Open gear waterproof grease composition and preparation method thereof

A lubricating grease composition and open gear technology, which is applied in the field of lubricating grease, can solve problems such as poor water resistance, extreme pressure and anti-wear performance, inability to fully meet equipment lubrication requirements, single dispersion of solid additives, etc., and achieve dispersion stability Good, easy to monitor, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

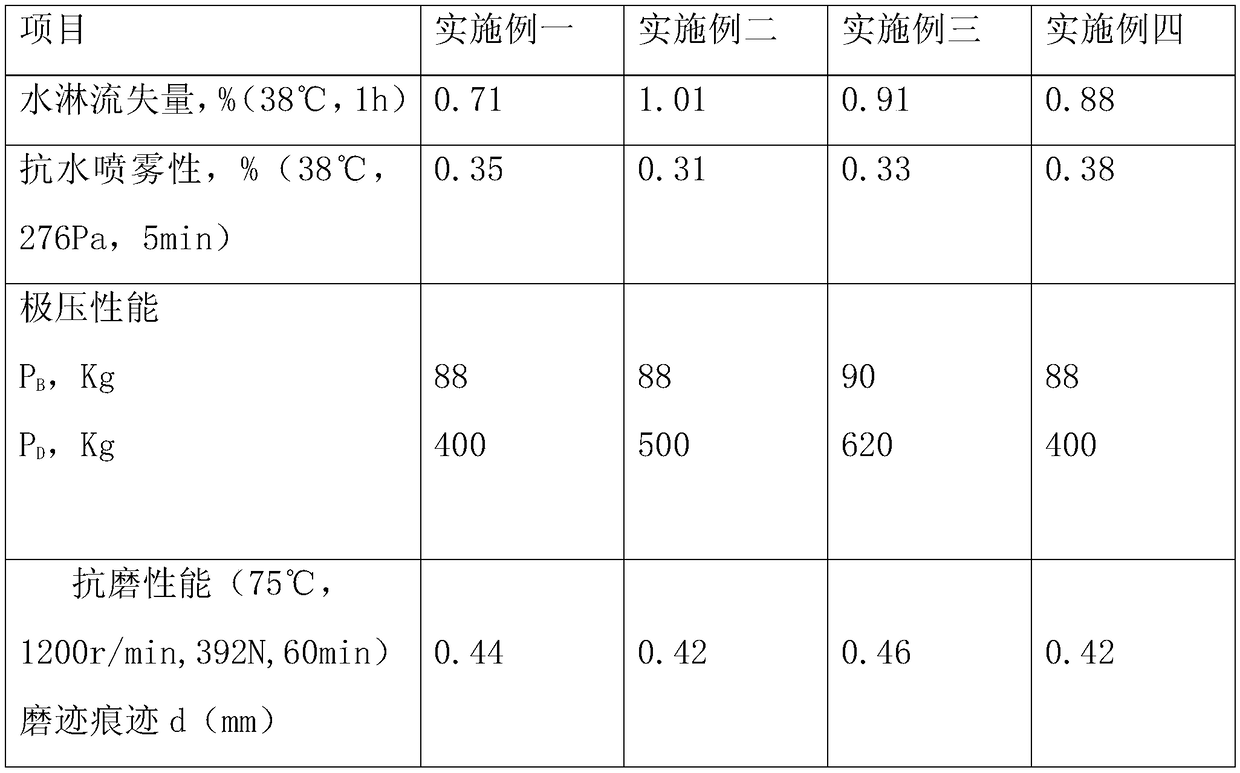

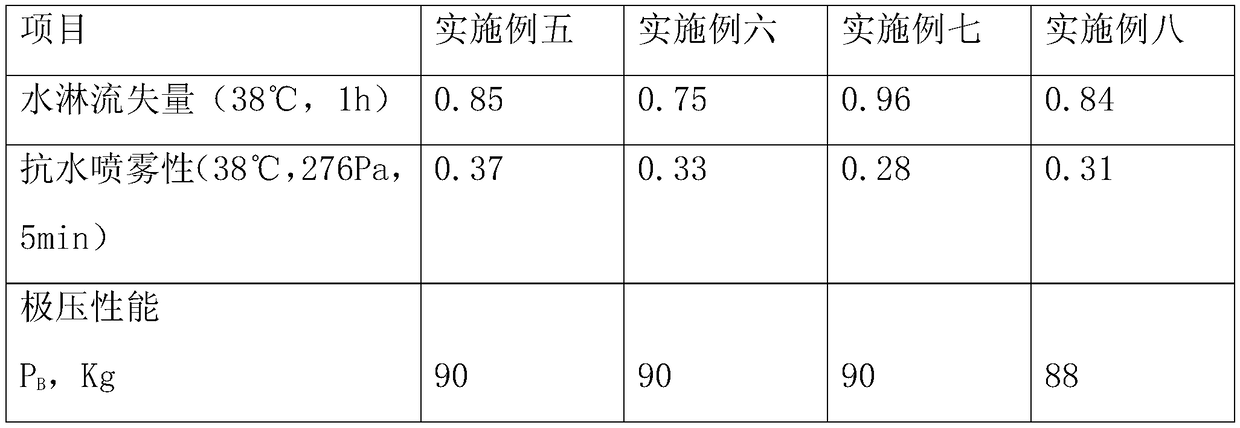

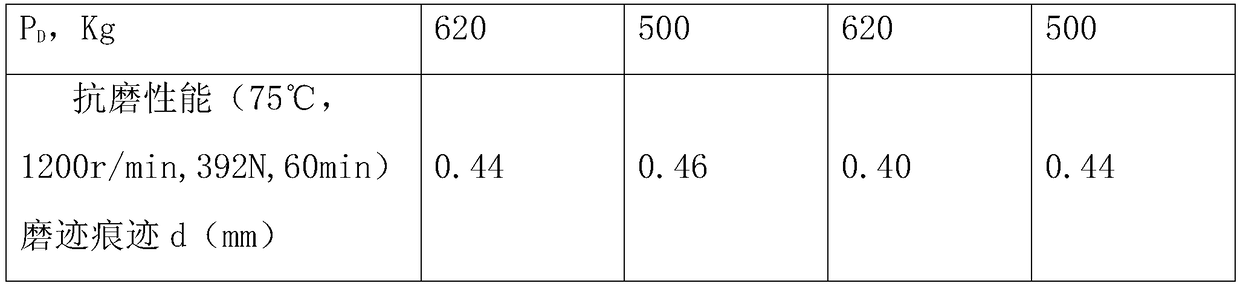

Examples

preparation example Construction

[0024] The preparation method of the open gear waterproof grease composition provided in this example includes the following steps: After uniformly mixing the components according to the set weight percentage, heating to a temperature of 60-80°C, and then grinding to obtain the open gear Type gear waterproof grease composition; it is preferable to uniformly mix each component according to the set weight percentage, heat to a temperature of 70°C, and then grind; Stable quality, excellent water resistance and extreme pressure anti-wear performance, proper heating and grinding is beneficial to reduce the viscosity of liquid raw materials, so that solid additives can be fully ground and dispersed.

[0025] In this example, all the raw materials used can be purchased from the market.

Embodiment 1

[0028] Take 50% of composite calcium sulfonate base grease, 25% of MCA, 10% of polyisobutylene (average molecular weight is 2400), 5% of fumed silicon dioxide, and 10% of zinc oxide (1000 mesh) in the small test kettle by weight percentage , after uniform mixing, heating to a temperature of 80° C., and then putting the heated mixture into a three-roll mill to grind until the solid additives are fully dispersed, thereby obtaining an open gear waterproof grease composition.

Embodiment 2

[0030] Take 80% of composite calcium sulfonate-based grease, 16% of MCA, 2% of polyisobutylene (average molecular weight of 1300), 1% of fumed silicon dioxide, and 1% of zinc oxide (500 mesh) in the small test kettle by weight percentage , after uniform mixing, heating to a temperature of 60° C., and then putting the heated mixture into a three-roll mill to grind until the solid additives are fully dispersed, and the open gear waterproof grease composition is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com