Longan pulp polysaccharide with enhanced functional activity and its green modification preparation method based on endogenous protein binding

A technology of longan pulp polysaccharide and functional activity is applied in the field of longan pulp polysaccharide and its green modification preparation based on the binding of endogenous proteins, and can solve the problems of weak biological activity of longan pulp polysaccharide, inability to meet development and utilization, residual toxic and harmful reagents, etc. , to avoid white matter co-precipitation, easy operation, and obvious effect of synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

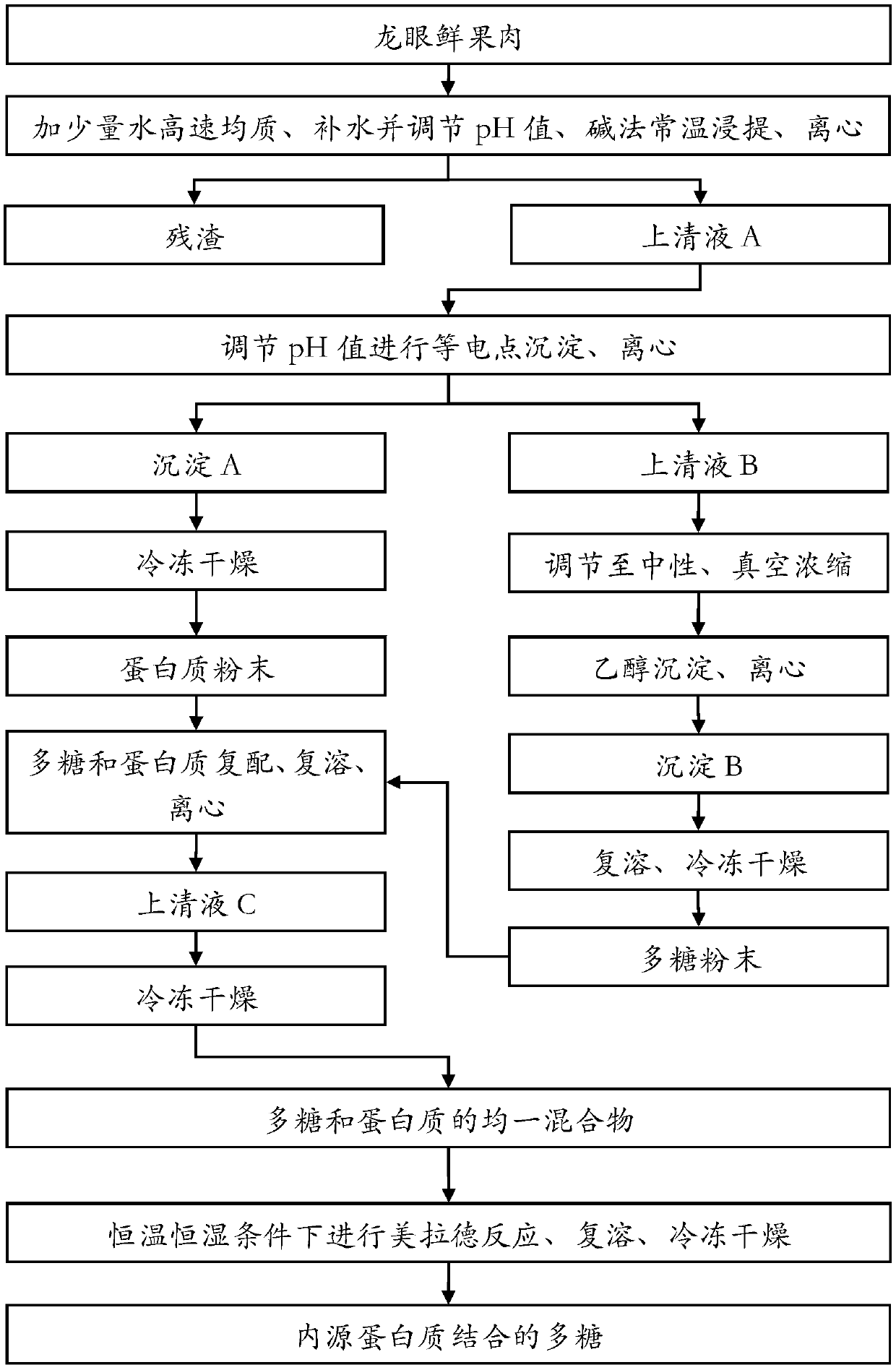

[0035] Preparation of longan pulp polysaccharide with enhanced functional activity, the process is as follows figure 1 shown.

[0036]Step 1): Take fresh longan pulp, add distilled water of 3 times the mass, and homogenize intermittently at 11000r / min at high speed for 3 times, each time for 3 minutes; add 6 times the mass of distilled water to the homogenate, and adjust the pH value 8.5, stirring and leaching at room temperature for 4 hours; after the leaching, centrifuge at 4500r / min for 10min, filter and separate the supernatant A, adjust its pH to 5, and after standing for 3h, centrifuge at 4500r / min for 10min to separate the precipitate A and the above The supernatant B and the precipitate A were washed with distilled water with a pH value of 5, and then freeze-dried to obtain the longan pulp protein.

[0037] Step 2): Take the supernatant B obtained in step 1) and adjust the pH to be neutral, concentrate in a vacuum to 1 / 4 volume, add ethanol to a volume concentration o...

Embodiment 2

[0040] Preparation of longan pulp polysaccharide with enhanced functional activity

[0041] Step 1): Take the fresh longan pulp, add distilled water of 2 times the mass, and homogenize twice at a high speed intermittently at 12000r / min for 4 minutes each time; add 5 times the mass of distilled water to the homogenate, and adjust the pH value 9. Stir and extract at room temperature for 3 hours; after the extraction, centrifuge at 5000r / min for 8min, filter and separate the supernatant A, adjust its pH value to 5.5, and after standing for 2h, centrifuge at 5000r / min for 8min to separate the precipitate A and the above The supernatant B and the precipitate A were washed with distilled water with a pH value of 5.5, and then freeze-dried to obtain the longan pulp protein.

[0042] Step 2): Take the supernatant B obtained in step 1) and adjust the pH to be neutral. After vacuum concentration to 1 / 3 volume, add ethanol to a volume concentration of 80%, and place it at 3°C for 14 ho...

Embodiment 3

[0045] Preparation of longan pulp polysaccharide with enhanced functional activity

[0046] Step 1): Take fresh longan pulp, add distilled water of 4 times the mass, and homogenize intermittently at 10,000 r / min at high speed for 4 times, each time for 2 minutes; add distilled water of 7 times the mass to the homogenate, and adjust the pH 8. Stir and extract at room temperature for 5 hours; after the extraction, centrifuge at 4000r / min for 12min, filter and separate the supernatant A, adjust its pH value to 4.5, and after standing for 4h, centrifuge at 4000r / min for 12min to separate the precipitate A and the above The supernatant B and the precipitate A were washed with distilled water with a pH value of 4.5, and then freeze-dried to obtain the longan pulp protein.

[0047] Step 2): Take the supernatant B obtained in step 1) and adjust the pH to be neutral, concentrate in vacuo to 1 / 5 volume, add ethanol to a volume concentration of 70%, and place it at 5°C for 10 hours to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com