Natto refined flour and making method thereof

A production method and technology of natto powder, applied in food science and other directions, can solve the problems of blood vessel wall damage, easy entry of lipids into the blood vessel wall, easy recurrence, etc., to increase blood vessel elasticity, prevent the formation of secondary thrombosis, enhance The effect of vascular toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

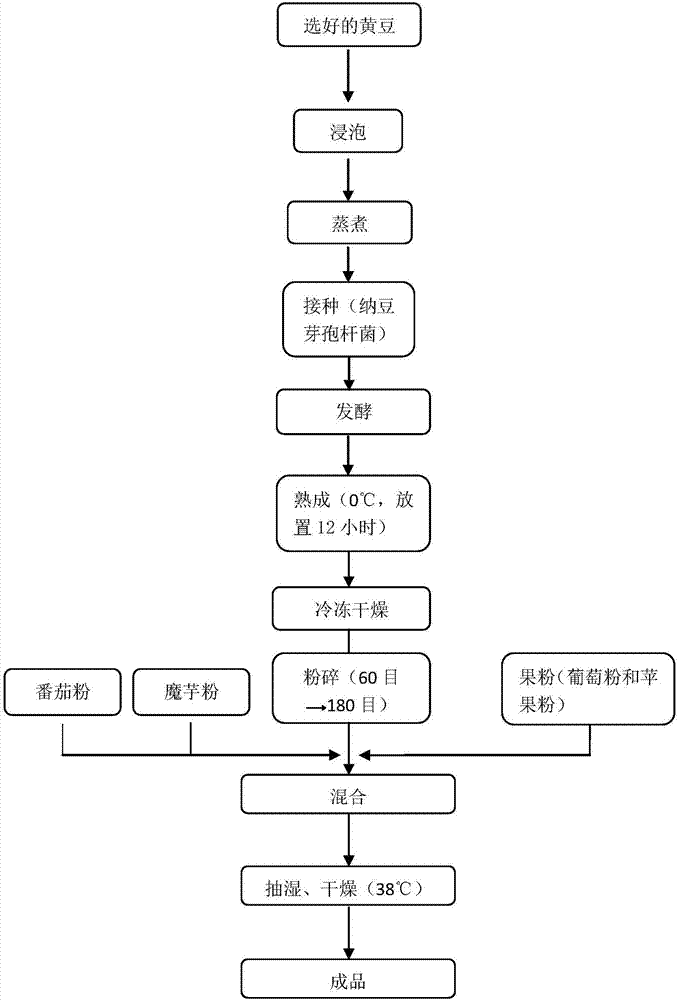

[0034] The production process of natto powder is as follows:

[0035] A. Production of natto

[0036] 1. Soybean pretreatment: The raw soybeans are manually graded and screened to remove impurities such as stones and sawdust mixed in the soybeans, and the soybeans with full grains, uniform sizes, and bright colors are manually selected;

[0037] 2. Soaking: wash the pretreated soybeans and add them to the nutrient solution at a weight ratio of 1:4 for immersion, soak for 20 hours at 7°C, and then rinse with pure water, wherein the nutrient solution includes the following components expressed in weight percentages : Sodium Selenite 0.02%, Magnesium Sulfate 0.2%, Sodium Chloride 0.2%, Chromium Chloride 0.01%, Purified Water 95.7%;

[0038] 3. Cooking: Put the soaked soybeans in a high-pressure steam pot and cook at 121°C for 25 minutes;

[0039] 4. Inoculation: Cool the boiled soybeans to 40°C, and inoculate Bacillus natto at an inoculation amount of 3% by spraying;

[0040] ...

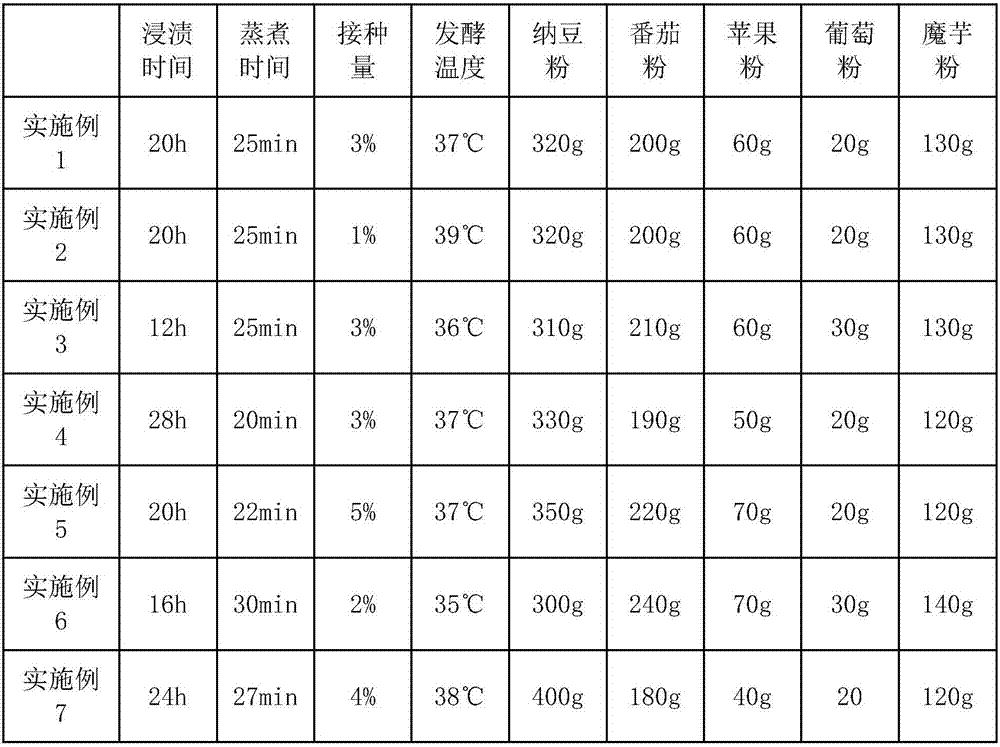

Embodiment 1 to 7

[0048] The natto sensory properties of embodiment 1 to 7 production:

[0049] For the natto produced by the process of Example 1-7, a white film is formed on the surface of the fermented natto, which is viscous and long in wire drawing, and the resulting natto is yellowish in color and has a metallic luster. Wherein the natto produced by the production process of Example 1 has the strongest viscosity and the longest wire drawing, and because nattokinase mainly exists in the viscous wire drawing of natto, it can be seen preliminarily from the sensory properties of natto that embodiment 1 The produced natto has a high content of nattokinase.

[0050] Measure the content of bacillus natto and nattokinase in the natto produced by embodiment 1 to embodiment 7 with colony plate counting method and FU ultraviolet spectrophotometry, as shown in table 2:

[0051]Table 2

[0052] Nattokinase (FU) Bacillus natto (1*109cfu / g) Example 1 1327 45 Example 2 1274 ...

experiment example A

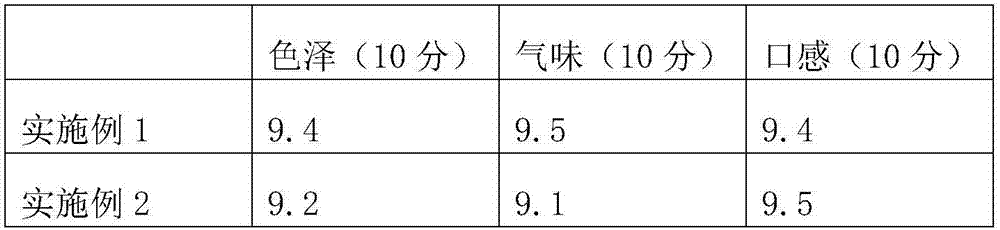

[0055] Experimental example A: natto fine powder sensory properties

[0056] Randomly choose 16-30 years old, 30-55 years old, 50-80 years old experimenter of three age groups is to the natto fine powder prepared by each embodiment in the present invention and commercially available pure natto powder product, fresh natto product The sensory aspects (color, smell, taste) were evaluated and scored, and the scoring results are shown in Table 3 below, wherein 30 subjects were selected for each age group, and the average value of the scores of a total of 90 subjects was taken as the final result. In the test, color: 10 is the subject's favorite color; smell: 10 is the highest score that the subject likes; taste: 10 is the highest score that the subject likes.

[0057] table 3

[0058]

[0059]

[0060] The results show that the freeze-dried natto powder prepared in Examples 1-7 is obviously superior to pure natto powder and fresh natto in terms of smell and mouthfeel, and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com