Molybdenum dioxide nano photothermal conversion material and preparation method and application thereof

A technology of molybdenum dioxide and nano-materials, which is applied in the field of molybdenum dioxide nano-photothermal conversion materials and its preparation, can solve the problems of affecting light absorption effect, poor biodegradability, and high energy consumption for synthesis, and achieve excellent photothermal Stability and biocompatibility, simple and fast preparation method, high active crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

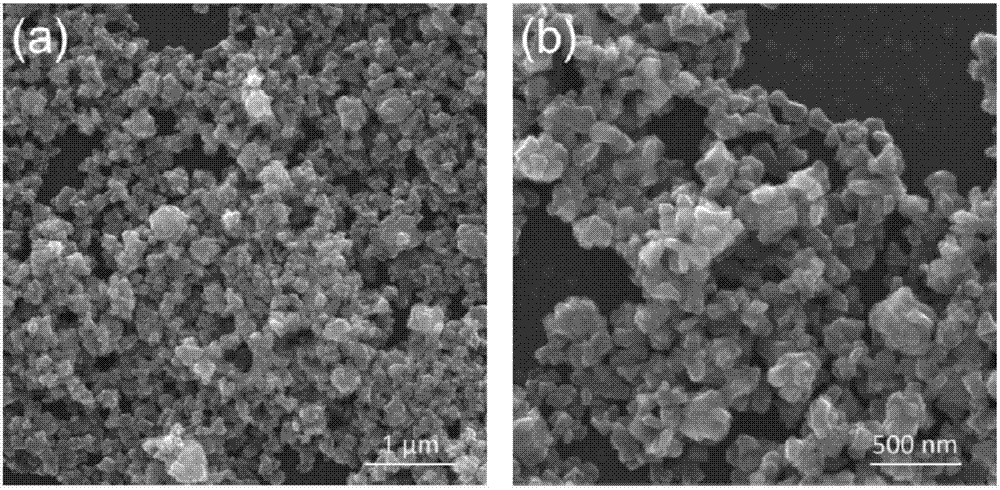

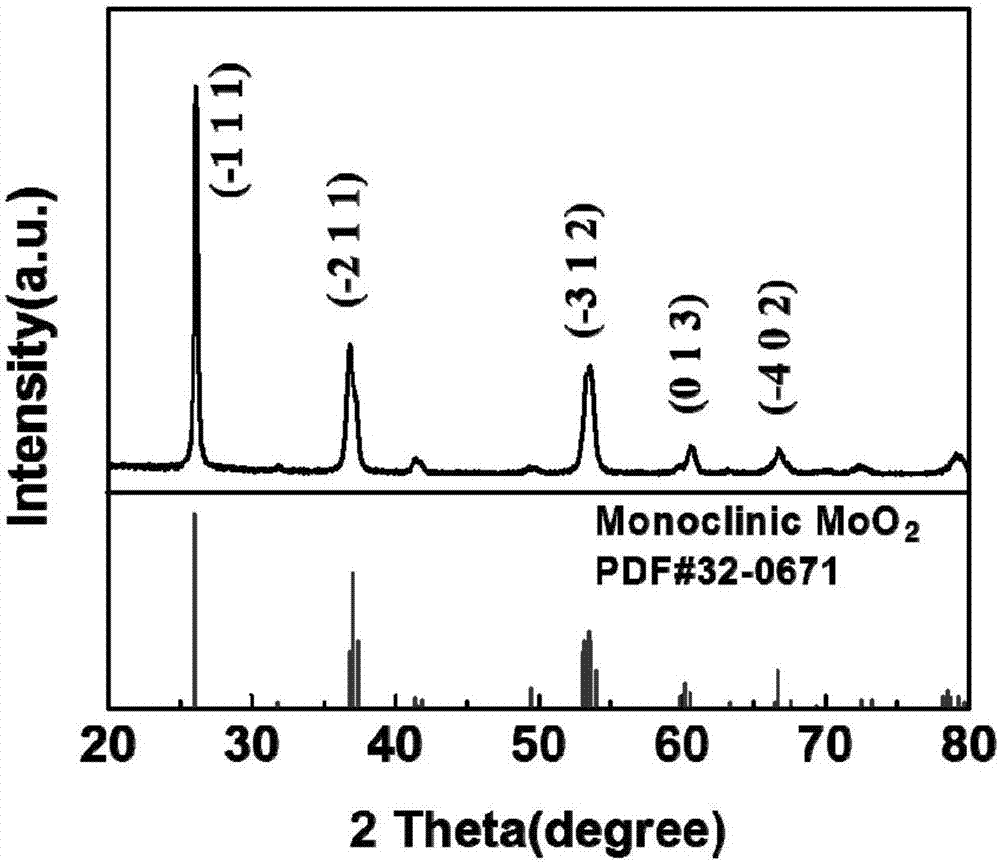

[0040] The combination of liquid phase laser ablation and solvothermal method is used to prepare molybdenum dioxide nano-photothermal conversion materials, which specifically includes the following steps:

[0041] Step 1, preparation of ethanol and H at a volume ratio of 2:1 2 o 2 The mixed solution, the high-purity molybdenum target (99.99%) is immersed in the mixed solution, stirred and mixed evenly;

[0042]Step 2, focusing a laser beam with a wavelength of 1064nm on the surface of simple molybdenum, with a laser pulse frequency of 10Hz, and ablating the molybdenum target for 20min under 250mJ laser energy to obtain a colloid containing molybdenum oxide nanoparticles;

[0043] Step 3. Insulate the colloid containing molybdenum oxide nanoparticles at 180°C for 2 hours, and perform solvothermal synthesis. After the reaction, cool to room temperature, remove the supernatant, and wash and centrifuge the bottom product of the reaction kettle with ethanol for 6 times. 8000r / min...

Embodiment 2

[0049] The combination of liquid phase laser ablation and solvothermal method is used to prepare molybdenum dioxide nano-photothermal conversion materials, which specifically includes the following steps:

[0050] Step 1, preparing ethanol and H at a volume ratio of 1:1 2 o 2 The mixed solution, the high-purity molybdenum target (99.99%) is immersed in the mixed solution, stirred and mixed evenly;

[0051] Step 2, focusing a laser beam with a wavelength of 1064nm on the surface of simple molybdenum, with a laser pulse frequency of 10Hz, and ablating the molybdenum target for 20min under 250mJ laser energy to obtain a colloid containing molybdenum oxide nanoparticles;

[0052] Step 3. Insulate the colloid containing molybdenum oxide nanoparticles at 160°C for 5 hours, and perform solvothermal synthesis. After the reaction, cool to room temperature, remove the supernatant, and wash and centrifuge the bottom product of the reaction kettle with ethanol for 6 times. 8000r / min, ce...

Embodiment 3

[0055] The combination of liquid phase laser ablation and solvothermal method is used to prepare molybdenum dioxide nano-photothermal conversion materials, which specifically includes the following steps:

[0056] Step 1, preparation of ethanol and H at a volume ratio of 2:1 2 o 2 The mixed solution, the high-purity molybdenum target (99.99%) is immersed in the mixed solution, stirred and mixed evenly;

[0057] Step 2, focusing a laser beam with a wavelength of 1064nm on the surface of simple molybdenum, with a laser pulse frequency of 10Hz, and ablating the molybdenum target for 45min under 100mJ laser energy to obtain a colloid containing molybdenum oxide nanoparticles;

[0058] Step 3. Insulate the colloid containing molybdenum oxide nanoparticles at 220°C for 2 hours, and perform solvothermal synthesis. After the reaction, cool to room temperature, remove the supernatant, and wash and centrifuge the bottom product of the reaction kettle with ethanol for 6 times. 8000r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com