A kind of preparation method and application of large-area graphene

A graphene and large-area technology, applied in the direction of graphene, nano-carbon, structural parts, etc., can solve the problems of lack of graphene surface functions, unfavorable large-scale production, and restricted material development, etc., to achieve low cost, short cycle, and process The effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

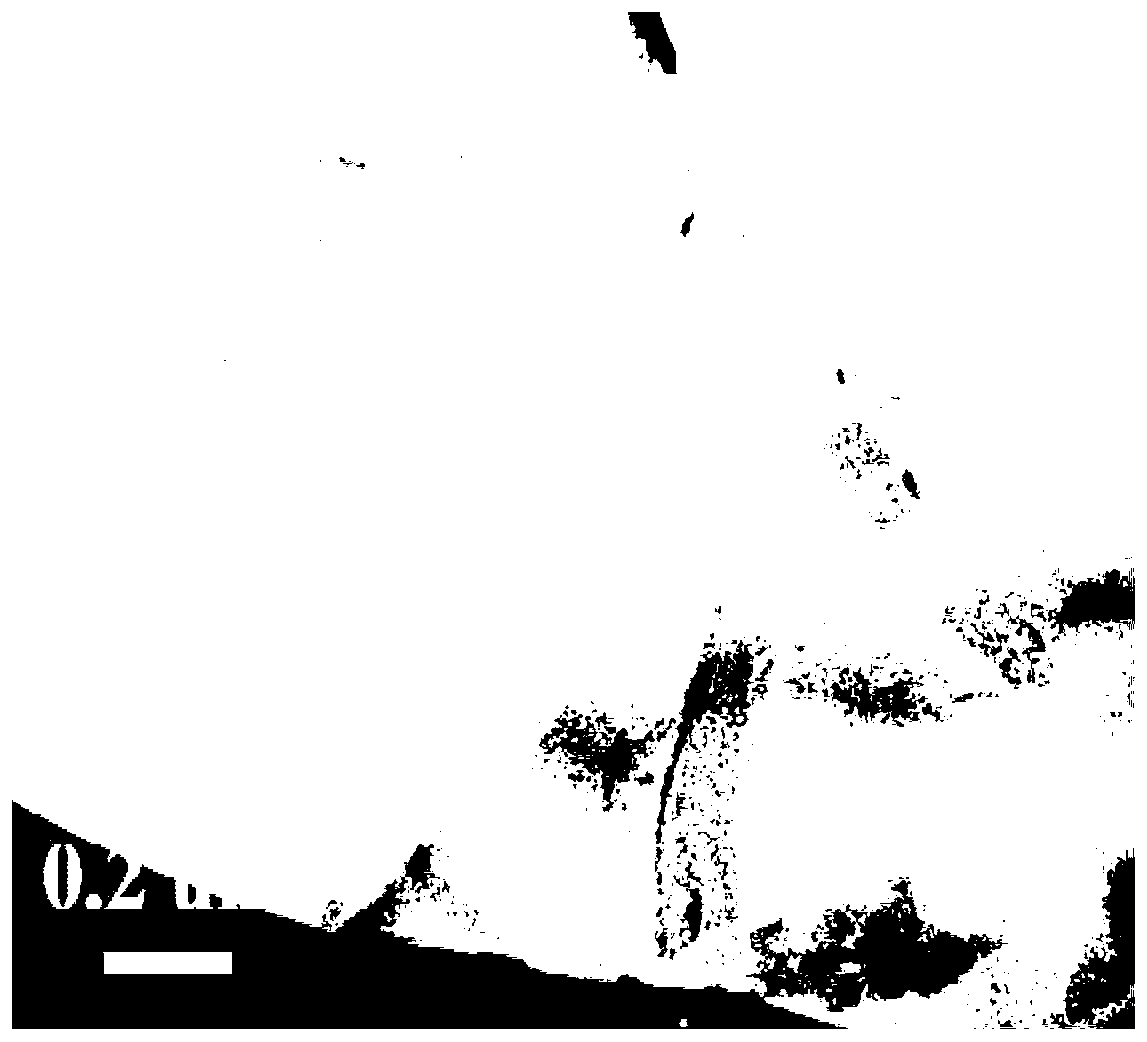

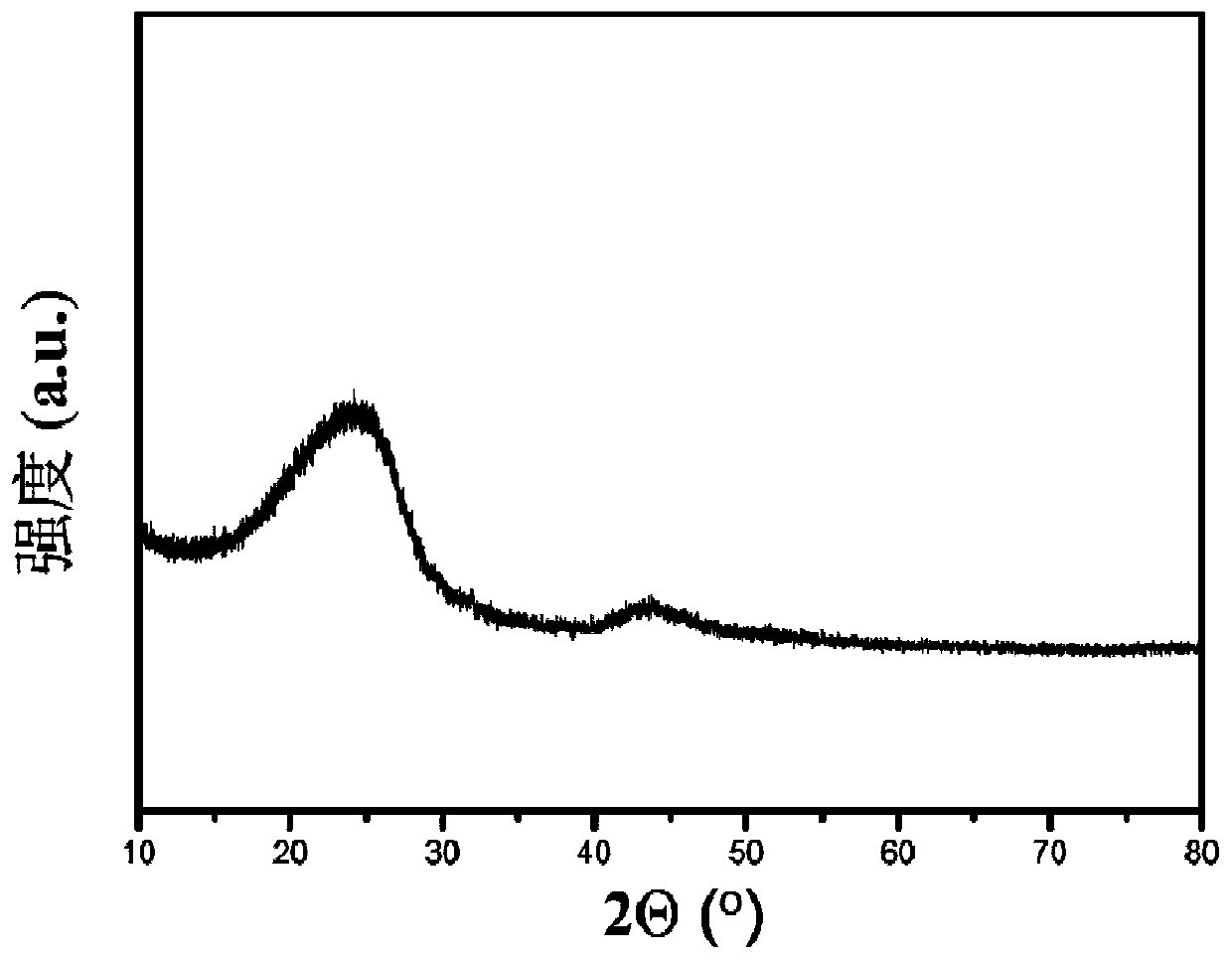

[0039] Mix 0.4g of carbon quantum dots and 4.0g of nickel chloride evenly, and then calcinate them at 700°C for 5h under the protection of Ar gas, with a heating rate of 10°C / min, and naturally cool down. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 10000r / min for 10min, wash with deionized water for 5 times, and vacuum dry at 100°C for 12h to obtain a black powder 0.16g. Its scanning electron microscope picture is figure 1 , it can be seen that the product is nano flakes (width can reach 30 μm). figure 2 Its transmission electron microscope picture is consistent with the scanning electron microscope result. image 3 Is its X-ray diffraction spectrum, the product that obtains is graphene carbon.

[0040] Mix the obtained graphene material, sodium carboxymethyl cellulose, and conductive carbon black evenly in a mass ratio of 70:15:15, add an appropriate amount of ultrapure water ...

Embodiment 2

[0042] Mix 0.4g PEG-6000 and 4.0g nickel chloride evenly, and then calcinate it at 750°C for 5h under the protection of Ar gas, with a heating rate of 8°C / min, and naturally cool down. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 10000r / min for 10min, wash with deionized water for 5 times, and vacuum dry at 100°C for 12h to obtain a black powder 0.15g. Its scanning electron microscope picture is Figure 4 , it can be seen that the product is a nano-sheet, and the surface area of the graphene material is relatively large (the width can reach 30 μm). Figure 5 Its transmission electron microscope picture is consistent with the scanning electron microscope result.

[0043] Mix the obtained graphene material, sodium carboxymethyl cellulose, and conductive carbon black evenly in a mass ratio of 70:15:15, add an appropriate amount of ultrapure water to make a slurry and apply it on th...

Embodiment 3

[0045] Mix 0.4g carbon quantum dots and 4.0g nickel chloride evenly, and then 2 Under gas protection, it was calcined at 800°C for 4h, the heating rate was 10°C / min, and the temperature was lowered naturally. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 10000r / min for 10min, wash with deionized water for 5 times, and vacuum dry at 100°C for 12h to obtain a black powder 0.13g. Its scanning electron microscope picture is Figure 6 , it can be seen that the product is nano flakes (width can reach 30 μm). Figure 7 Its transmission electron microscope picture is consistent with the scanning electron microscope result.

[0046] Mix the obtained graphene material, sodium carboxymethyl cellulose, and conductive carbon black evenly in a mass ratio of 70:15:15, add an appropriate amount of ultrapure water to make a slurry and apply it on the copper foil, and place it in the After drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com