High performance NdFeB rare earth permanent magnet material and preparation method thereof

A rare earth permanent magnet, neodymium iron boron technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of easy sliding or rotation of magnetic powder, difficult control of magnet oxidation, and high requirements for hot pressing molds. The effect of micro-porosity, short sintering time and comprehensive magnetic properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

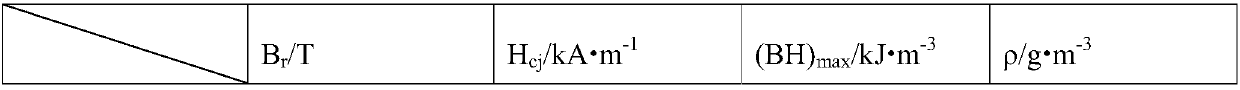

Embodiment 1

[0033] This embodiment prepares 27.17Nd-70.59Fe-1.02B-0.72Al-0.5Cu rare earth permanent magnet material, and the process steps are as follows:

[0034] (1) Ingredients

[0035] Dosing according to the chemical formula of the above-mentioned rare earth permanent magnet materials, and remove the oxides and inclusions on the surface of the metal raw materials;

[0036] (2) Casting

[0037] Put the raw materials prepared in step (1) into a vacuum induction melting furnace and melt them under the condition of high-purity argon. After melting, pour the alloy liquid on a water-cooled copper roller with a linear speed of 3m / s, and then quickly cool it to obtain Quick-setting alloy cast sheet with an average thickness of 0.25mm;

[0038] (3) Preparation of magnetic powder

[0039] Put the alloy cast sheet obtained in step (2) into a rotary hydrogen explosion furnace for hydrogen absorption-dehydrogenation treatment to obtain coarsely crushed alloy particles with a particle size of 1...

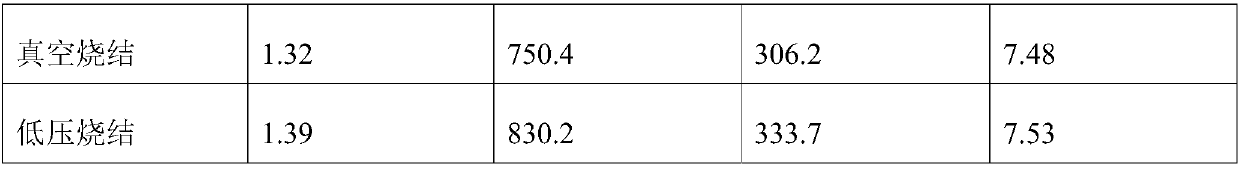

Embodiment 2

[0054] This embodiment prepares 29.28Nd-68.15Fe-1.02B-0.85Al-0.7Cu rare earth permanent magnet material, and the process steps are as follows:

[0055] (1) Ingredients

[0056] Dosing according to the chemical formula of the above-mentioned rare earth permanent magnet materials, and remove the oxides and inclusions on the surface of the metal raw materials;

[0057] (2) Casting

[0058] Put the raw materials prepared in step (1) into a vacuum induction melting furnace and melt them under the condition of high-purity argon. After melting, pour the alloy liquid on a water-cooled copper roller with a linear speed of 3m / s, and then quickly cool it to obtain Quick-setting alloy cast sheet with an average thickness of 0.25mm;

[0059] (3) Preparation of magnetic powder

[0060] Put the alloy cast sheet obtained in step (2) into a rotary hydrogen explosion furnace for hydrogen absorption-dehydrogenation treatment to obtain coarsely crushed alloy particles with a particle size of 1...

Embodiment 3

[0074] This example prepares 29.82(Nd,Pr)-62.42Fe-4.97Co-1.0B-0.83Ga-0.96Cu rare earth permanent magnet material, and the process steps are as follows:

[0075] (1) Ingredients

[0076] Dosing according to the chemical formula of the above-mentioned rare earth permanent magnet materials, and remove the oxides and inclusions on the surface of the metal raw materials;

[0077] (2) Melting and casting: put the raw materials prepared in step (1) into a vacuum induction melting furnace, melt under the condition of high-purity argon, and pour the alloy liquid on a water-cooled copper roller with a linear speed of 3m / s after melting, that is Quick-setting alloy cast sheets with an average thickness of 0.25mm can be obtained after rapid cooling;

[0078] (3) Preparation of magnetic powder

[0079] Put the alloy cast sheet obtained in step (2) into a rotary hydrogen explosion furnace for hydrogen absorption-dehydrogenation treatment to obtain coarsely crushed alloy particles with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com