Method for Improving Sludge Coal-Water Slurry Slurry Performance Through Sludge Pretreatment

A technology for pretreatment and sludge water, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc. It can solve the problems of complex sludge components, water cannot flow freely, viscosity rise, etc., to improve the concentration and sludge mixing. Mixed volume, obvious social and economic benefits, simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

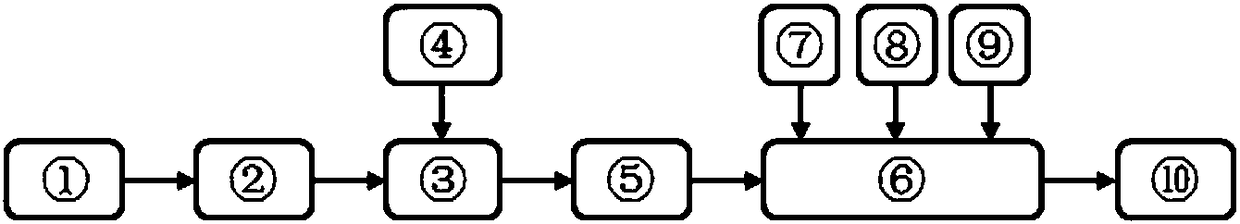

Method used

Image

Examples

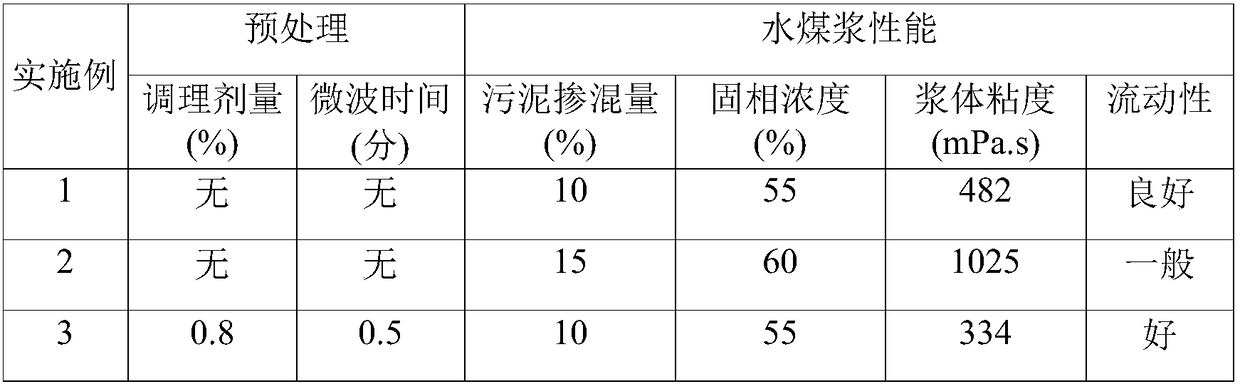

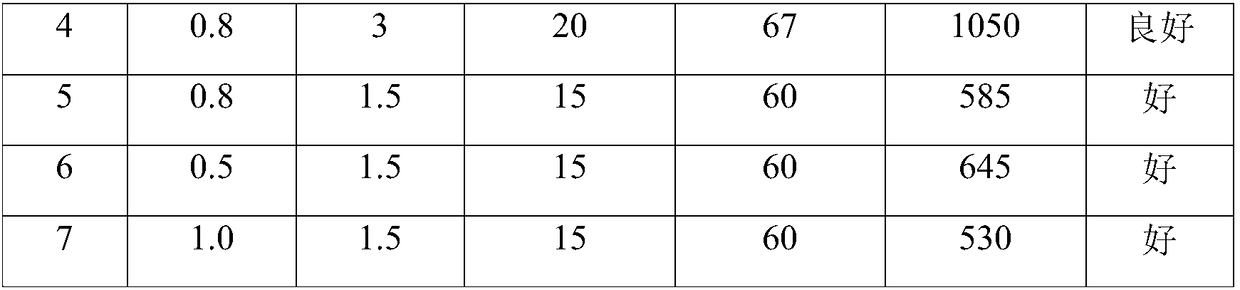

Embodiment 1

[0028] Material:

[0029]The sludge is mechanically dehydrated sludge from a sewage treatment plant in Hangzhou, with a moisture content of about 80%. The coal is bituminous coal from Yanzhou, Shandong, and the air-dry basis moisture, ash, volatile matter and fixed carbon are 1.18%, 15.24%, 29.50% and 54.08%, respectively. The additive is sodium methylene naphthalene sulfonate-sodium styrene sulfonate-sodium maleate.

[0030] step:

[0031] Calculate the amount of wet sludge, coal (particle size ≤ 4mm), water and additives required for pulping according to the estimated concentration of coal-water slurry. The sludge is not pretreated, and the corresponding quality of sludge, coal particles and corresponding proportions of water and additives are put into the variable frequency planetary ball mill, which occupies about one-third of the volume of the ball mill tank, and then according to the test requirements Put a certain proportion of steel balls (the diameters of large, me...

Embodiment 2

[0035] Material:

[0036] The sludge is the sludge after sewage treatment of a petrochemical enterprise in Nanjing, with a moisture content of about 80%. The coal is bituminous coal from Yanzhou, Shandong, and the air-dry basis moisture, ash, volatile matter and fixed carbon are 1.18%, 15.24%, 29.50% and 54.08%, respectively. The additive is calcium lignosulfonate.

[0037] step:

[0038] Calculate the amount of wet sludge, coal (particle size ≤ 4mm), water and additives required for pulping according to the estimated concentration of coal-water slurry. The sludge is not pretreated, and the corresponding quality of sludge, coal particles and corresponding proportions of water and additives are put into the variable frequency planetary ball mill, which occupies about one-third of the volume of the ball mill tank, and then according to the test requirements Put a certain proportion of steel balls (the diameters of large, medium and small balls are: 20mm, 10mm, and 6mm respect...

Embodiment 3

[0042] Material:

[0043] The sludge is mechanically dehydrated sludge from a sewage treatment plant in Hangzhou, with a moisture content of about 80%. The coal is bituminous coal from Yanzhou, Shandong, and the air-dry basis moisture, ash, volatile matter and fixed carbon are 1.18%, 15.24%, 29.50% and 54.08%, respectively. The additive is sodium methylene naphthalene sulfonate-sodium styrene sulfonate-sodium maleate. Conditioning agent is potassium chloride.

[0044] step:

[0045] Calculate the amount of wet sludge, conditioner, coal (particle size ≤ 4mm), water and additives required for pulping according to the estimated concentration of coal-water slurry. The sludge is pretreated, and the corresponding quality of sludge and conditioner is mixed evenly and then put into the microwave radiation device for modification for 0.5min. 1. The additive is packed into the frequency conversion planetary ball mill, and the steps of Example 1 are repeated later.

[0046] Mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com