Photo-cured printing ink for gold-plating resistant potion and application of photo-cured printing ink

A light-curing ink and potion technology, which is applied in inks, applications, household appliances, etc., can solve the problems of not being able to meet the high precision of PCB, the resolution depends on the precision, and the poor performance of gold-plating potion, so as to improve the performance of gold-plated potion, High resolution, good performance of resistance to gold plating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

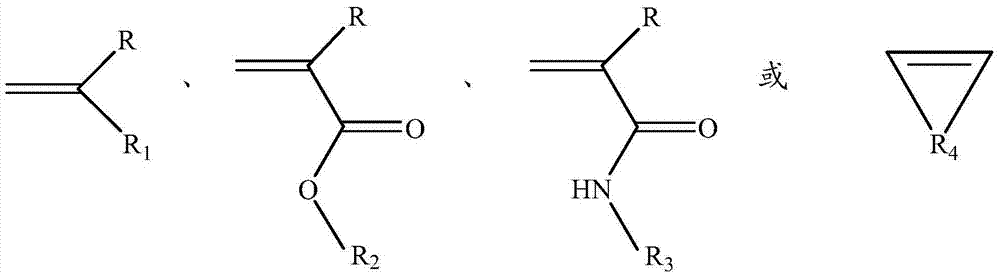

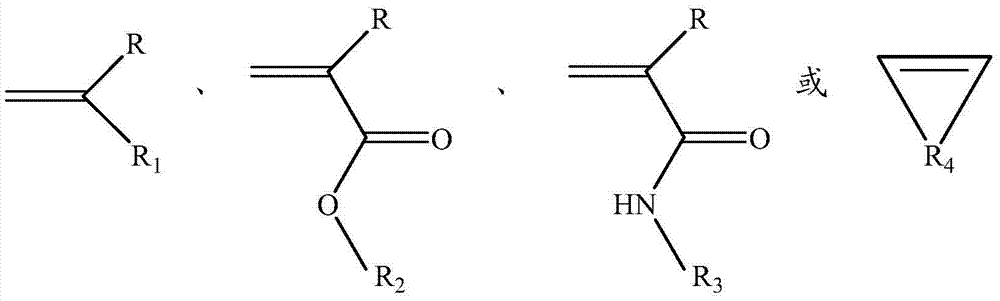

[0056] Further, in the above-mentioned photocurable ink, the esterified styrene-maleic anhydride copolymer resin can be obtained through esterification reaction between alcohol and styrene-maleic anhydride copolymer resin. The specific synthesis method includes: polymerizing maleic anhydride and styrene to obtain styrene-maleic anhydride copolymer resin; reaction to obtain esterified styrene maleic anhydride copolymer resin. The specific kind of alcohol used is not strictly limited, but alcohols with 1 to 10 carbon atoms are preferred, because alcohols with 1 to 10 carbon atoms are in liquid state and can be used not only as reactants but also as reaction media during the reaction , to make the reaction milder, which is very beneficial for increasing the reaction rate and conversion rate of the esterification reaction. More preferred are monohydric alcohols having 1 to 10 carbon atoms, such as propanol, butanol, pentanol, hexanol, heptanol, octanol, nonanol, decanol, isopropa...

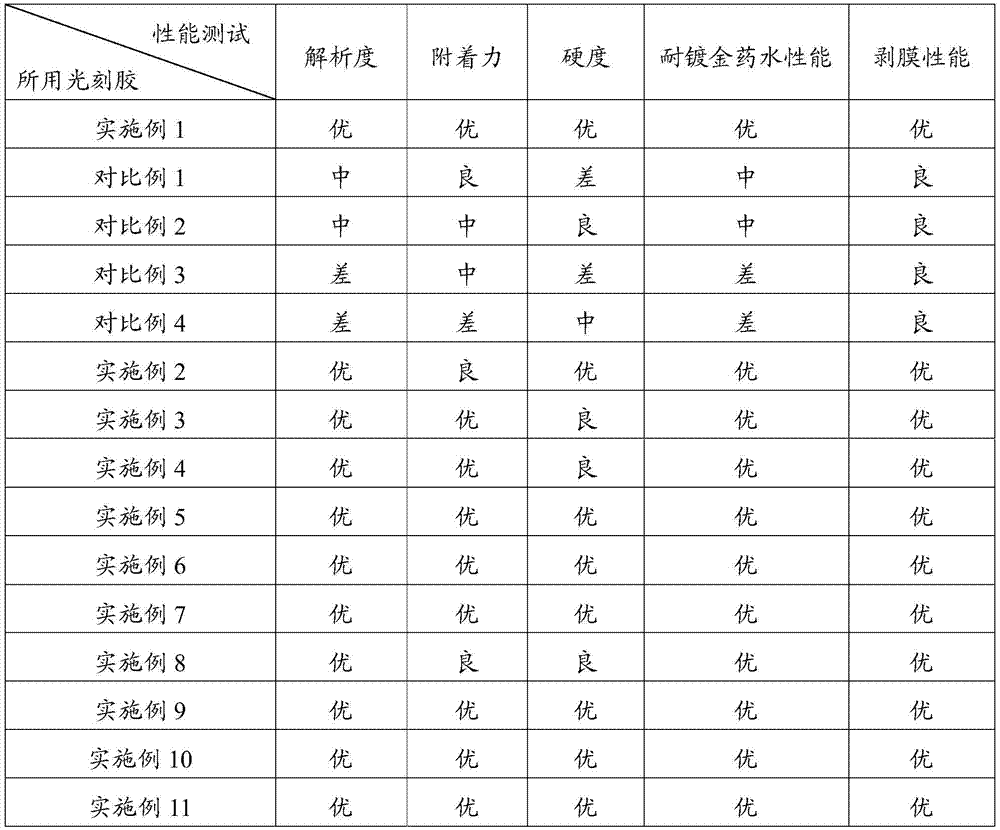

Embodiment 1

[0102] This embodiment provides a photocurable ink resistant to gold-plating potion, the photocurable ink includes the following components by weight:

[0103] Acrylic acid copolymer resin, 10 parts;

[0104] Esterified styrene-maleic anhydride copolymer resin, 10 parts;

[0105] Trimethylolpropane triacrylate, 14 parts;

[0106] 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone, 2 parts;

[0107] Talcum powder, 30 parts;

[0108] Propylene glycol methyl ether acetate, 30;

[0109] Phthalo blue, 2 parts;

[0110] Leveling agent, 1 part; defoamer, 1 part by weight.

[0111] The photocurable ink of this embodiment is obtained after mixing the above components uniformly in proportion.

[0112] Wherein, the acrylic acid copolymer resin is obtained by copolymerizing acrylic acid and methyl methacrylate, its weight average molecular weight is 100,000 (Mw), its molecular weight distribution index is 1.95, and its acid value is 150 mgKOH / g. Based on the total mass of acr...

Embodiment 2

[0137] This embodiment provides a photocurable ink resistant to gold-plating potion, the photocurable ink includes the following components by weight:

[0138] Methacrylic acid copolymer resin, 5 parts;

[0139] Esterified styrene-maleic anhydride copolymer resin, 25 parts;

[0140] Dipentaerythritol hexaacrylate, 5 parts;

[0141] Benzoin dimethyl ether, 6 parts; 2-isopropyl thioxanthone, 2 parts;

[0142] Silica, 5 parts;

[0143] Propylene glycol methyl ether acetate, 42 parts;

[0144] phthalo green, 5 parts;

[0145] Leveling agent, 1 part; adhesion promoter, 1 part; defoamer, 3 parts.

[0146] The photocurable ink of this embodiment is obtained after mixing the above components uniformly in proportion.

[0147] Among them, the methacrylic acid copolymer resin is obtained by copolymerizing methacrylic acid, methyl acrylate and cyclopentene, and has a weight average molecular weight of 10,000 (Mw), a molecular weight distribution index of 1.70, and an acid value of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com