A high-dielectric and high-magnetic nickel-doped barium ferrite ceramic material and its preparation method

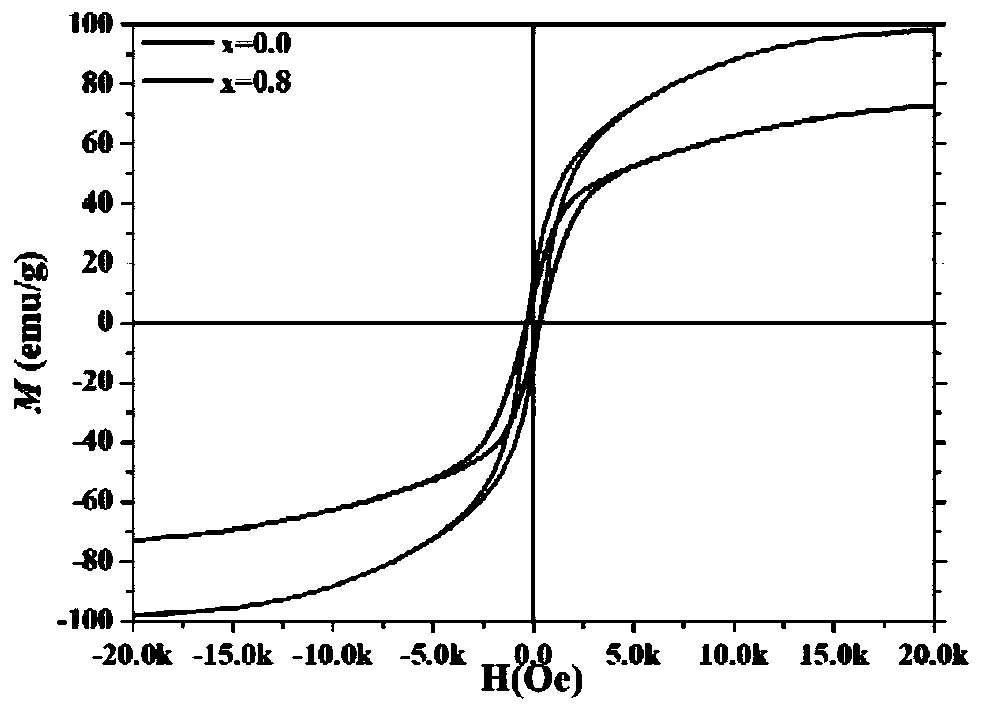

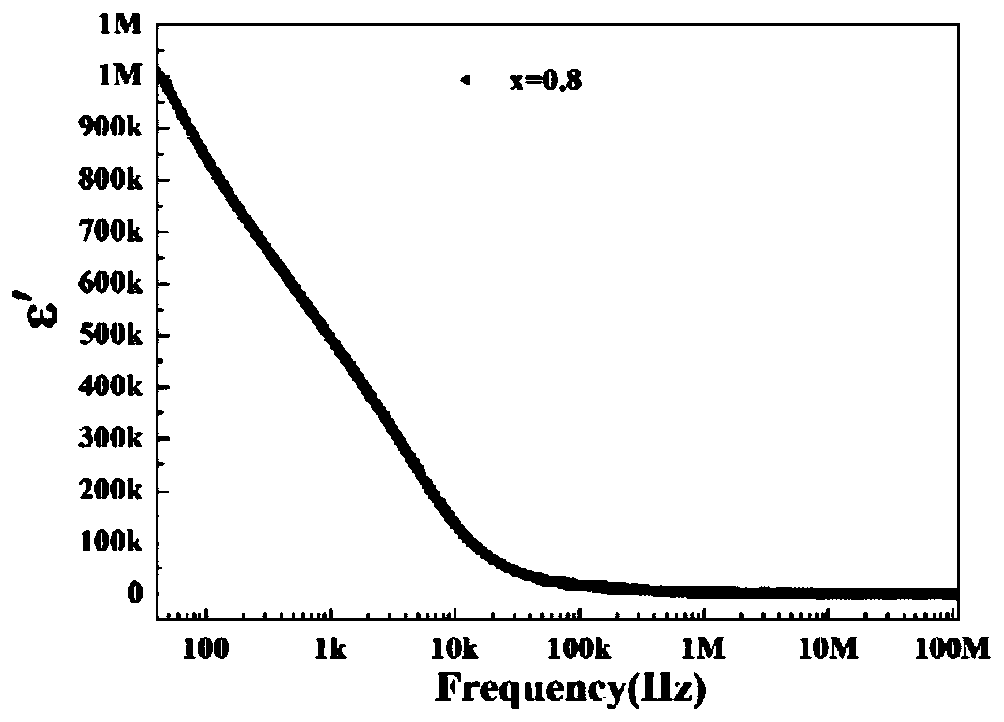

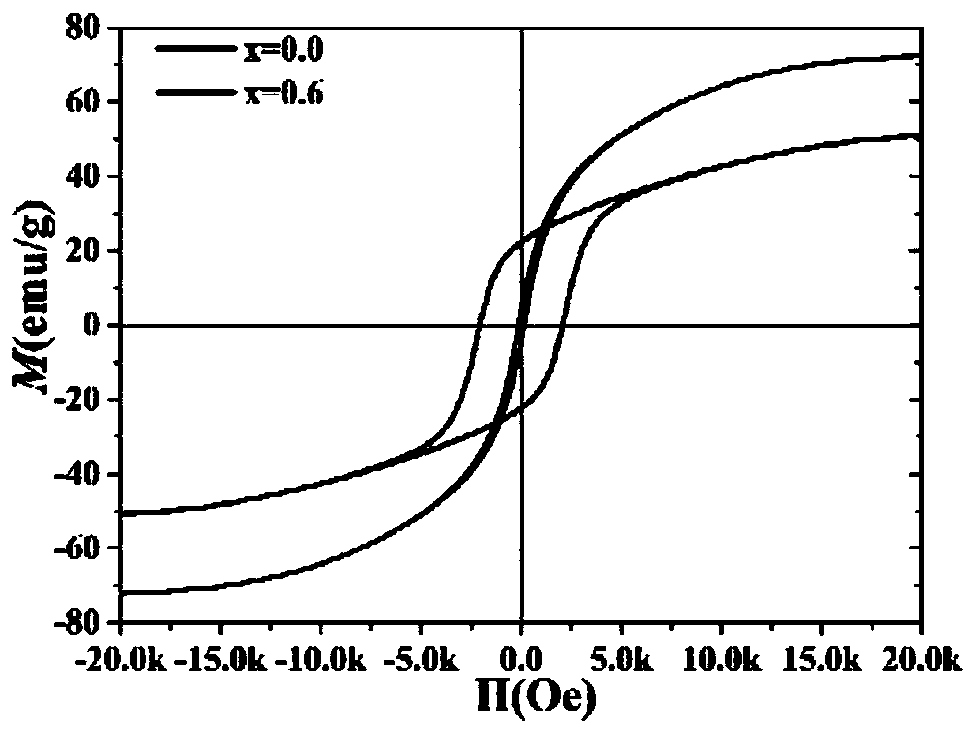

A technology of barium ferrite and ceramic materials, which is applied in the field of nickel-doped single-phase barium ferrite ceramic materials, can solve the problems of decrease in saturation magnetization, insignificant increase in saturation magnetization, and large loss, and achieve simple preparation methods, Excellent high-dielectric and high-magnetic properties, the effect of increasing magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] (1) According to the molar ratio of 1:11.2:0.8, mix 2.613g of barium nitrate, 45.248g of iron nitrate nonahydrate and 2.362g of nickel nitrate hexahydrate. Then add 39.086g of citric acid monohydrate as complexing agent. After adding 300 mL of deionized water, stir for 2 hours until the solute is completely dissolved to obtain the desired solution;

[0028] (2) Add ammonia water to the above solution, adjust the pH value to 7, heat and stir in a water bath at 85° C. for 4 hours, and volatilize the solvent to obtain a sol precursor;

[0029] (3) drying the obtained sol precursor at 100-120°C for 3-4 days to obtain a fluffy xerogel;

[0030] (4) Heat the dry gel at a rate of 5 °C / min to 210 °C for 1.5 hours, then continue to increase the temperature at a rate of 5 °C / min to 450 °C for 2 hours, and finally increase the temperature at a rate of 10 °C / min After holding at 800°C for 3 hours, and then cooling in the furnace, the precursor of nickel-doped barium ferrite powde...

example 2

[0034] (1) According to the molar ratio of 1:11.4:0.6, mix 2.613g of barium nitrate, 46.056g of iron nitrate nonahydrate and 1.745g of nickel nitrate hexahydrate. Then add 39.296g of citric acid monohydrate as complexing agent. After adding 320 mL of deionized water, stir for 1.5 h until the solute is completely dissolved to obtain the desired solution;

[0035] (2) Add ammonia water to the above solution, adjust the pH value to 7, heat and stir in a water bath at 88° C. for 3 hours, and volatilize the solvent to obtain a sol precursor;

[0036] (3) drying the obtained sol precursor at 118° C. for 4 days to obtain a fluffy xerogel;

[0037] (4) Heat the dry gel at a rate of 8 °C / min to 210 °C for 1.5 hours, then continue to increase the temperature at a rate of 5 °C / min to 450 °C for 2 hours, and finally increase the temperature at a rate of 10 °C / min After reaching 800°C, keep it warm for 3 hours, and then cool down with the furnace to obtain the nickel-doped barium ferrite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com