Solid polymer electrolyte, preparation method thereof, composite positive pole and solid-state lithium-ion battery

A solid polymer and electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve the problems of low temperature cycle performance of batteries, poor Coulomb efficiency rate performance, low conductivity lithium ion migration number, etc. Low-temperature electrochemical performance, improved ionic conductivity, and the effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

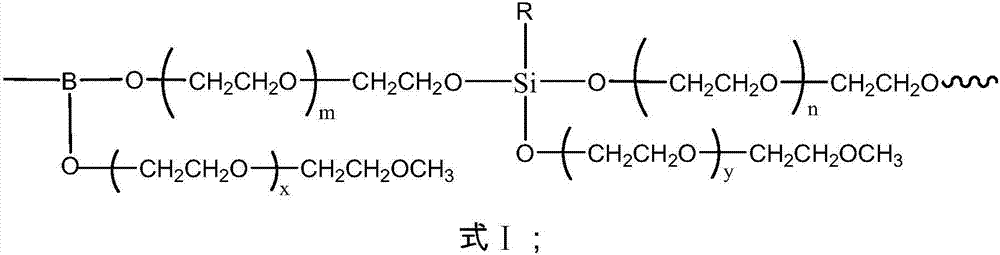

[0041] The present invention also provides a method for preparing the solid polymer electrolyte described in the above technical solution, comprising the following steps:

[0042] (1) Boron oxide, polyethylene glycol and polyethylene glycol monomethyl ether are mixed and heated to obtain a prepolymer;

[0043] (2) adding silane dropwise to the prepolymer obtained in the step (1), and polymerizing to obtain a comb polymer;

[0044] (3) adding a crosslinking agent dropwise to the comb polymer obtained in step (2) to obtain a network polymer precursor;

[0045] (4) mixing the network polymer precursor obtained in the step (3) with a lithium salt, and performing a crosslinking reaction to obtain a solid polymer electrolyte;

[0046] The steps (1), (2) and (3) are carried out under anhydrous and oxygen-free conditions.

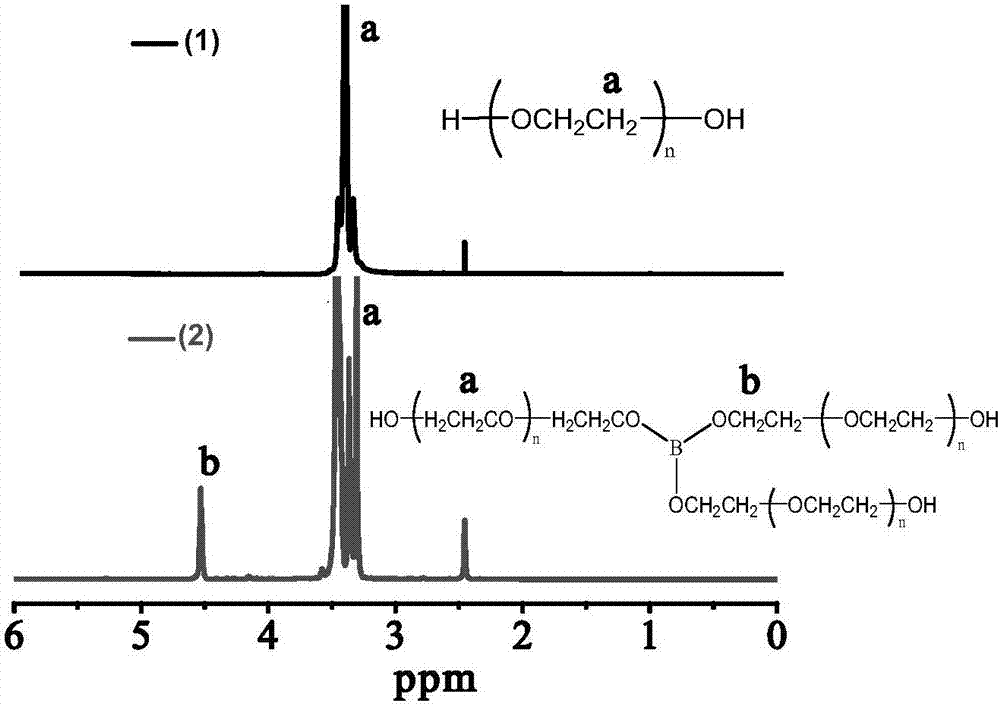

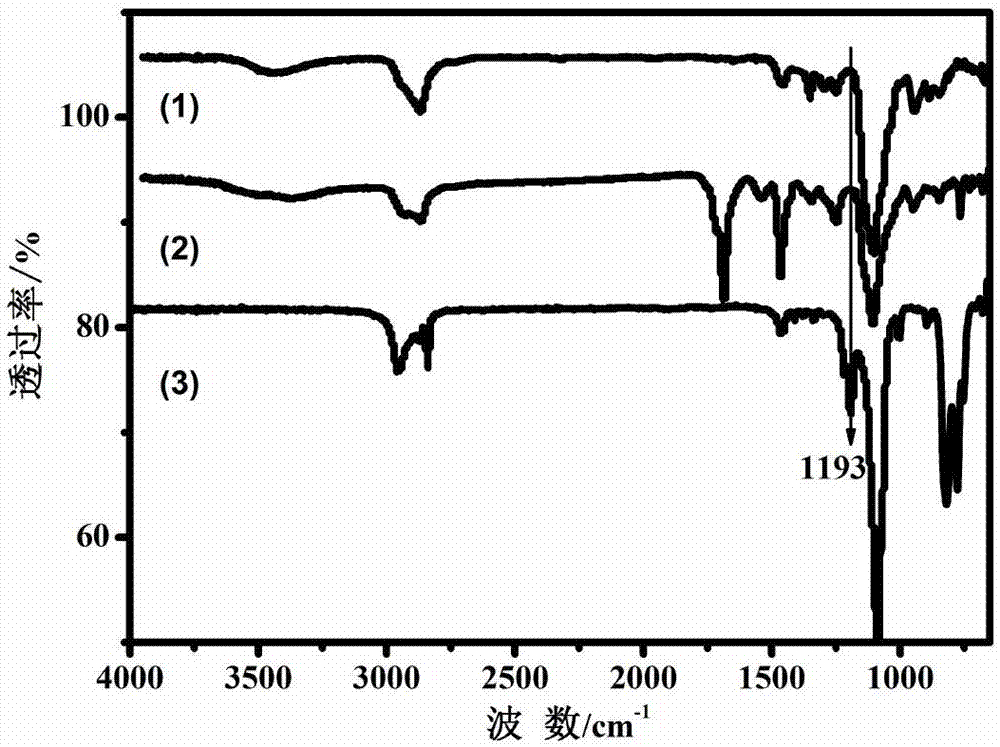

[0047] The invention mixes boron oxide, polyethylene glycol and polyethylene glycol monomethyl ether, and heats to obtain a prepolymer. In the present invention...

Embodiment 1

[0078] (1) Boron oxide, polyethylene glycol and polyethylene glycol monomethyl ether were stirred and mixed at 50 r / min for 12 hours, and heated to 60° C. to obtain a prepolymer;

[0079] (2) Add 0.01mL / s of silane dropwise to the prepolymer obtained in the step (1), adjust the pH value to 5, 60°C, stir at 50r / min for 20min and polymerize to obtain a comb polymer;

[0080] (3) 0.012mL / s drop crosslinking agent in the comb polymer that described step (2) obtains, obtain network polymer precursor;

[0081] (4) Stir and mix the network polymer precursor obtained in the step (3) with lithium salt and tetrahydrofuran at 200r / min for 5h. The concentration of the polymer is 10%. The cross-linking reaction obtains a solid polymer electrolyte with a thickness of 100 μm and a diameter of 16 mm;

[0082] The steps (1), (2) and (3) are carried out under anhydrous and oxygen-free conditions, and the step (4) is carried out under an air environment.

[0083] The silane is n-propyltrimetho...

Embodiment 2

[0089] The solid polymer electrolyte prepared in Example 1, the active material, the conductive agent and the binder were ball milled and mixed with a solvent at 300r / min for 24 hours to obtain a mixed material; the active material was lithium cobaltate with a mass fraction of 60%, and the solid polymer The mass fraction of the electrolyte is 20%, the mass fraction of the binder polyvinylidene fluoride is 5%, and the mass fraction of the conductive agent acetylene black is 15%.

[0090] The mixed material was coated and dried at 100° C. for 36 hours, and sliced to obtain a composite positive electrode with a thickness of 80 μm and a diameter of 19 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com