Austenitic heat-resistant steel and preparation method thereof

A technology of austenitic heat-resistant steel and matrix, which is applied in the field of high-temperature metal structural materials, can solve problems such as poor structural stability and affect the safe operation of power stations, reduce grain boundary interface energy, and improve resistance to steam oxidation and flue gas. Corrosion ability, the effect of improving the toughness of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

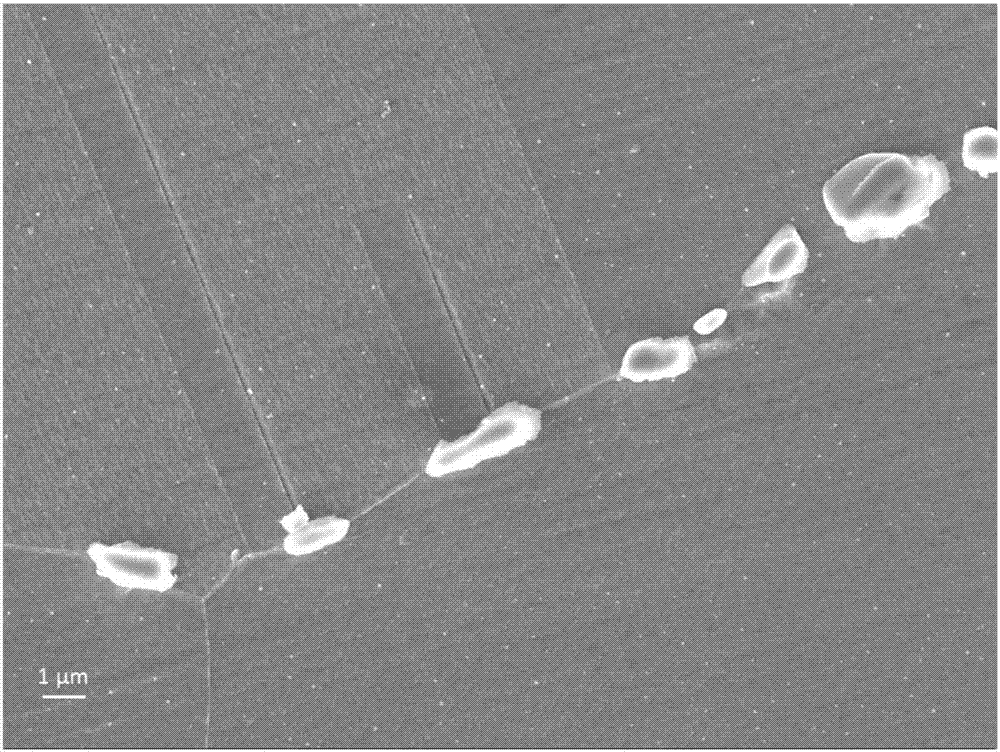

Image

Examples

Embodiment 1-3

[0026] 1. Alloy composition

[0027] What Table 1 provided is the chemical composition of Examples 1, 2, and 3 of the present invention. Alloys 1#-3# used in the test are the austenitic alloys of Examples 1, 2, and 3 of the present invention. In order to compare with the commercial HR3C alloy, the composition of HR3C is also listed in the table.

[0028] The chemical composition (% by weight, balance is Fe) of the embodiment 1-3 of the present invention and comparative example (HR3C) of table 1

[0029]

[0030] 2. Alloy melting and thermal deformation

[0031] 19-25% Ni, 20-25% Cr, 1.0-6.0% Co, ≤1.0% Mn, 0.2-0.8% Nb, 0-0.5% V, ≤1.0% Si by weight percentage , 0.1-0.3% of N, 0.04-0.10% of C, 0.001-0.003% of B, 0-0.04% of Ce, 0.01-0.03% of P, the balance is Fe, added to the vacuum induction furnace for melting, pouring into alloy ingots.

[0032] Homogenize the alloy ingot at 1150-1200°C for 20-30 hours, then heat deform (hot forging or hot rolling) the homogenized alloy ...

Embodiment 4-7

[0049] Table 4 shows the chemical composition of Examples 4, 5, 6 and 7 of the present invention. Alloys 4#-6# used in the test are the austenitic alloys of Examples 4, 5, 6 and 7 of the present invention.

[0050] The chemical composition (% by weight, balance is Fe) of the embodiment of the present invention 4-7 of table 4

[0051] alloy Ni Cr mn Nb Si N C B P co V Ce 4# 25 20 0.1 0.8 1.0 0.1 0.04 0.002 0.07 1.0 0.25 0.015 5# 22 25 0.8 0.6 0.75 0.15 0.087 0.003 0.014 5.0 0.5 - 6# 19 23 0.3 0.2 0.66 0.25 0.10 0.001 0.01 6.0 0.3 0.04 7# 20 22 1.0 0.4 0.90 0.3 0.046 0.001 0.022 2.0 - 0.02

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com