Method for deeply cleaning and removing cobalt by wet hydrometallurgy

A technology of hydrometallurgy and deep purification, which is applied in the direction of improving process efficiency, can solve the problems of increasing the cost of auxiliary materials and electricity consumption, the inability of the production system to run for a long time, and affecting the electrolytic efficiency of the zinc system, so as to solve the problems of cobalt complexation solution problem, easy industrial implementation, and excellent cobalt removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

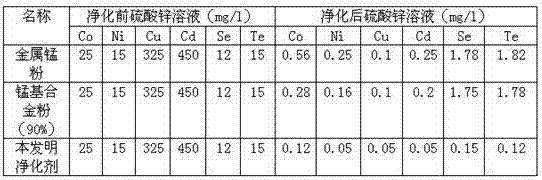

Image

Examples

Embodiment 1

[0026] Embodiment 1, a method for deep purification and removal of cobalt in zinc hydrometallurgy, comprising the following steps:

[0027] Step 1), put the neutral leach supernatant containing 148 g / l of zinc and 0.035 g / l of cobalt leached from zinc calcined sand into the first-stage purification tank, and control the temperature of the first-stage purification to 55°C, according to the total amount of copper and cadmium The amount of zinc powder is calculated as 2 times of the content. Add zinc powder, react for 1h, and filter through a filter press to obtain a section of copper cadmium slag and a filtered liquid. The Cu in the filtered liquid is 0.001g / l, and the Cd is 0.02g / l. l;

[0028] Step 2), heat up the filtered liquid in step 2 to 85-90°C and place it in the second-stage purification tank, and then pass through the second-stage purification 1# tank, the second-stage purification 2# tank, the second-stage purification 3# tank, Add zinc powder and antimony salt to t...

Embodiment 2

[0030] Embodiment 2, a method for deep purification and removal of cobalt in zinc hydrometallurgy, comprising the following steps:

[0031] Step 1), put the neutral leach supernatant containing 152 g / l of zinc and 0.052 g / l of cobalt leached from zinc calcined sand into the first-stage purification tank, and control the temperature of the first-stage purification to 65°C, according to the total amount of copper and cadmium. The amount of zinc powder is calculated as 3 times of the content. Add zinc powder, react for 1.5h, and filter through a filter press to obtain a section of copper cadmium residue and a filtered liquid. The Cu in the filtered liquid is 0.0015g / l, and the Cd is 0.028g. / l;

[0032] Step 2), heat up the filtered liquid in step 2 to 85-90°C and place it in the second-stage purification tank, and then pass through the second-stage purification 1# tank, the second-stage purification 2# tank, the second-stage purification 3# tank, Add zinc powder and antimony sa...

Embodiment 3

[0034] Embodiment 3, a method for deep purification and removal of cobalt in zinc hydrometallurgy, comprising the following steps:

[0035] Step 1), put the neutral leaching supernatant containing 140 g / l of zinc and 0.045 g / l of cobalt leached from zinc calcined sand into the first-stage purification tank, and control the temperature of the first-stage purification to 60°C, according to the total amount of copper and cadmium. The amount of zinc powder is calculated as 2.5 times of the content. Add zinc powder, react for 1.5h, and filter through a filter press to obtain a section of copper cadmium residue and a filtered liquid. The Cu in the filtered liquid is 0.0013g / l, and the Cd is 0.022g. / l;

[0036] Step 2), heat up the filtered liquid in step 2 to 85-90°C and place it in the second-stage purification tank, and then pass through the second-stage purification 1# tank, the second-stage purification 2# tank, the second-stage purification 3# tank, Add zinc powder and antimo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com