Extrusion and forging integrated forming process of large diameter aq80m magnesium alloy cake

A forming process, magnesium alloy technology, applied in the direction of metal extrusion, metal processing equipment, metal extrusion control equipment, etc., can solve the problems of reduced mechanical properties, large total deformation, easy cracking of ingots, etc., to reduce intermediate The effect of the number of annealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

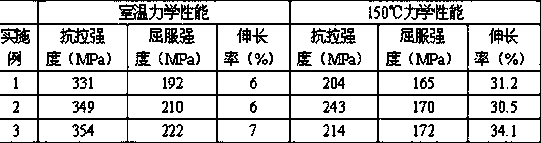

[0028] Magnesium alloy ingots with a diameter of Φ610mm and a length of 1650mm were prepared by semi-continuous casting, homogenized, air-cooled to room temperature, and descaled. Heat the extrusion die and keep the temperature at 360°C; heat the extrusion barrel and keep the temperature at 370°C; heat the billet to 420°C for 1 hour, and then carry out low extrusion ratio extrusion billet opening. The extrusion ratio is 3.6, and the extrusion speed is 1.2mm / s. After extrusion, a rod with a diameter of Φ300mm is obtained. The bars were cut into long 630mm bars. After the rod-shaped blank is kept at 410°C for 1 hour, it is thickened and compressed on a hydraulic press. The reduction of the forging pass is 10-25%, and the intermediate annealing is carried out for 6 passes to obtain a magnesium alloy with a diameter of Φ695mm and a height of 110mm. Cake material, 175℃ / 36h aging treatment. physical map see figure 1 , and its mechanical properties are shown in Table (1).

Embodiment 2

[0030] A magnesium alloy ingot with a diameter of Φ620mm and a length of 1600mm was prepared by semi-continuous casting, homogenized, air-cooled to room temperature, and descaled. Heat the extrusion die and keep the temperature at 390°C; heat the extrusion barrel and keep the temperature at 400°C; heat the ingot to 380°C for 1.5 hours, and then carry out low extrusion ratio extrusion. The extrusion ratio is 4, and the extrusion speed is 2mm / s. After extrusion, a rod with a diameter of Φ300mm is obtained. The bars were cut into long 630mm bars. After the rod-shaped blank is kept at 415°C for 1 hour, it is thickened and compressed on a hydraulic press. The reduction of the forging pass is 15-30%, and the intermediate annealing is carried out for 5 passes to obtain a magnesium alloy with a diameter of Φ700mm and a height of 100mm. Cake material, 175℃ / 36h aging treatment. Its mechanical properties are shown in Table (1).

Embodiment 3

[0032] A magnesium alloy ingot with a diameter of Φ610mm and a length of 1650mm was prepared by semi-continuous casting, homogenized, air-cooled to room temperature, and descaled. Heat the extrusion die and keep the temperature at 360°C; heat the extrusion barrel and keep the temperature at 370°C; heat the ingot to 360°C and keep it for 2 hours, then perform low extrusion ratio extrusion to open the billet. The extrusion ratio is 3.6, and the extrusion speed is 1.6mm / s. After extrusion, a rod with a diameter of Φ300mm is obtained. The bars were cut into long 630mm bars. After the rod-shaped blank is kept at 400°C for 1 hour, it is thickened and compressed on a hydraulic press. The reduction of the forging pass is 15-20%, and the intermediate annealing is carried out for 5 passes to obtain a magnesium alloy with a diameter of Φ700mm and a height of 100mm. Cake material, 175℃ / 36h aging treatment. Its mechanical properties are shown in Table (1)

[0033] Table (1) Mechanical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com