Catalyst for preparing methylal and methyl formate through one-step selective oxidation of methanol

The technology of methyl formate and catalyst is applied in the field of catalysts for preparing methylal and methyl formate by one-step selective oxidation of methanol, and can solve the problems of harsh conditions, low conversion rate, low selectivity and the like, and achieve good anti-sintering performance, Good dispersion and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 4.0g of vanadyl sulfate, 17.4g of titanium sulfate and 8.6g of sulfuric acid were dissolved in a three-necked flask containing 680ml of deionized water, dissolved under stirring, and 0.5g of activated carbon dispersant was added to obtain solution A; 40ml of ammonia (25%) was dissolved in Prepare solution B in 360ml deionized water. Place A under an ice-water bath and stir vigorously, and drop B into the mixture A at a speed of 110 r / min until the pH=9.0, and a slurry containing a yellow-brown precipitate is obtained. Continue to stir for 0.5h, then leave it to age for 2h, wash twice with 100ml of water to obtain a tan solid, dissolve the obtained tan solid in a solution of 15ml of water and 35ml of n-butanol, stir for 6h, and then suction filter to obtain filter cake C , C was dried at 110°C for 2h, and calcined at 400°C for 6h to obtain a catalyst for the selective oxidation of methanol to prepare methylal and methyl formate.

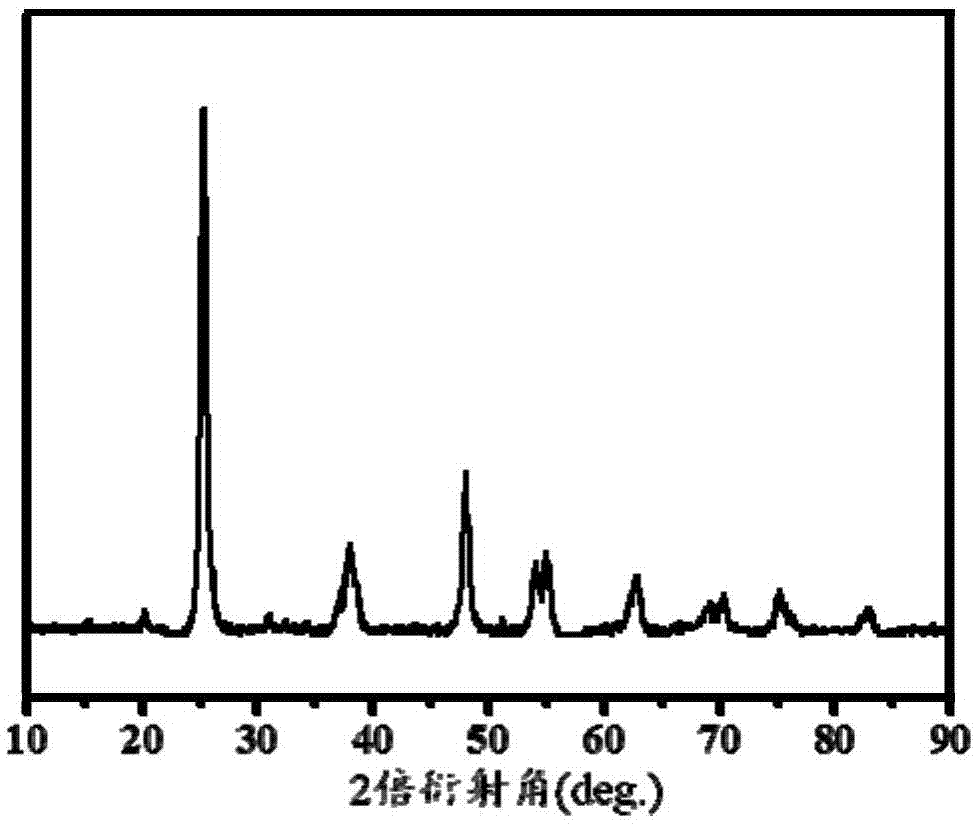

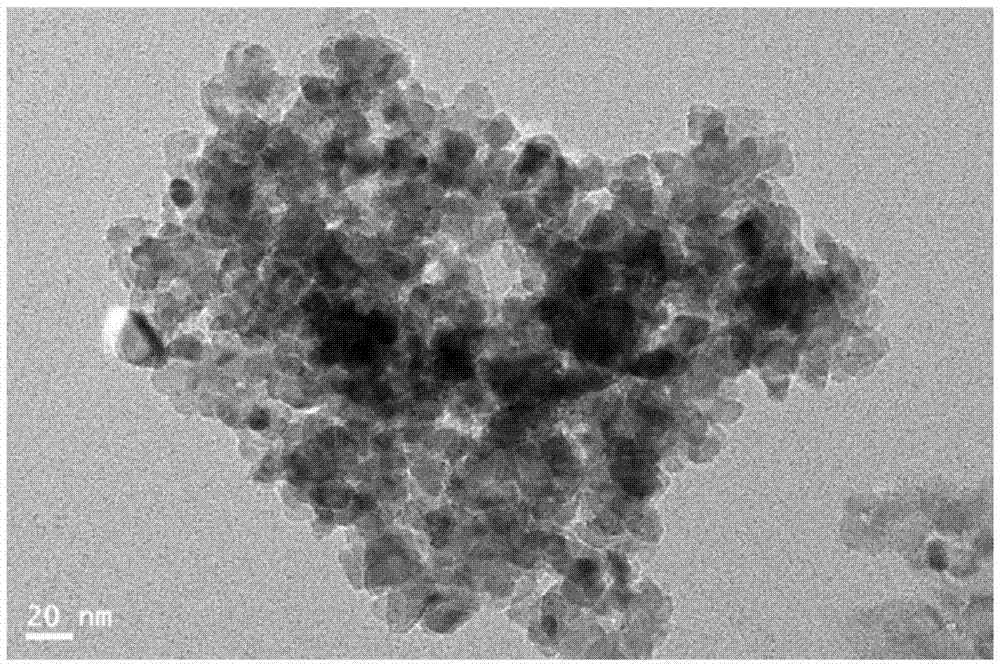

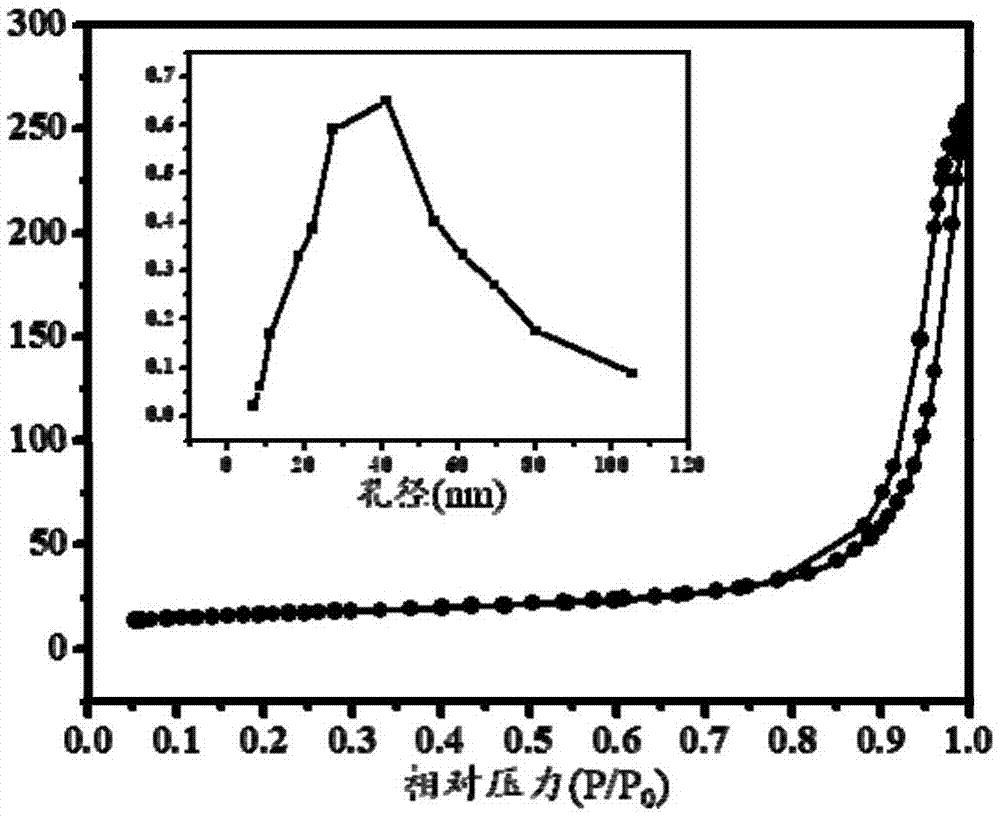

[0047] attached figure 1 As the XRD ch...

Embodiment 2

[0056] 4.2g of vanadyl sulfate, 17.4g of titanium sulfate and 8.6g of sulfuric acid were dissolved in a three-necked flask containing 680ml of deionized water, dissolved under stirring, and 1.0g of activated carbon dispersant was added to obtain solution A; 40ml of ammonia (28%) was dissolved in Prepare solution B in 360ml deionized water. Place A under an ice-water bath and stir vigorously, and drop B into the mixture A at a speed of 110 r / min until the pH=9.5, and a slurry containing a yellow-brown precipitate is obtained. Continue to stir for 0.5h, then leave it to age for 2h, wash twice with 100ml of water to obtain a tan solid, dissolve the obtained tan solid in a solution of 15ml of water and 35ml of n-butanol, stir for 6h, and then suction filter to obtain filter cake C , C was dried at 100°C for 2h, and calcined at 430°C for 6h to obtain a catalyst for the selective oxidation of methanol to prepare methylal and methyl formate.

[0057] The obtained catalyst was presse...

Embodiment 3

[0061] 3.5g of vanadyl sulfate, 17g of titanium sulfate and 6.3g of sulfuric acid were dissolved in a three-necked flask filled with 680ml of deionized water, dissolved under stirring, and 1.5g of active carbon dispersant was added to obtain solution A; 50ml of ammonia (18%) was dissolved in 450ml of deionized water was prepared as solution B. Place A under an ice-water bath and stir vigorously, and drop B into the mixture A at a speed of 130 r / min until the pH=9.3, and a slurry containing a yellow-brown precipitate is obtained. Continue to stir for 0.5h, then leave it to age for 2h, wash with 100ml of water for 3 times to obtain a tan solid, dissolve the obtained tan solid in a solution of 15ml of water and 35ml of Tween, stir for 7h, and then suction filter to obtain filter cake C. Dry C at 120°C for 2 hours, and roast at 400°C for 6 hours to obtain a catalyst for the selective oxidation of methanol to prepare methylal and methyl formate.

[0062] The prepared catalyst was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com