Graphene-coated silicon nanoparticle with novel structure, and preparation method thereof

A technology coated with silicon nanoparticles and graphene, which is applied to structural parts, electrical components, electrochemical generators, etc., can solve the problems of slow electron transfer rate, pollution of the environment by waste liquid containing Cu ions, and separation of active material particles and current collectors. and other issues, to achieve high-rate charge-discharge performance and safety performance, to facilitate large-scale production, and to reduce the effect of battery volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

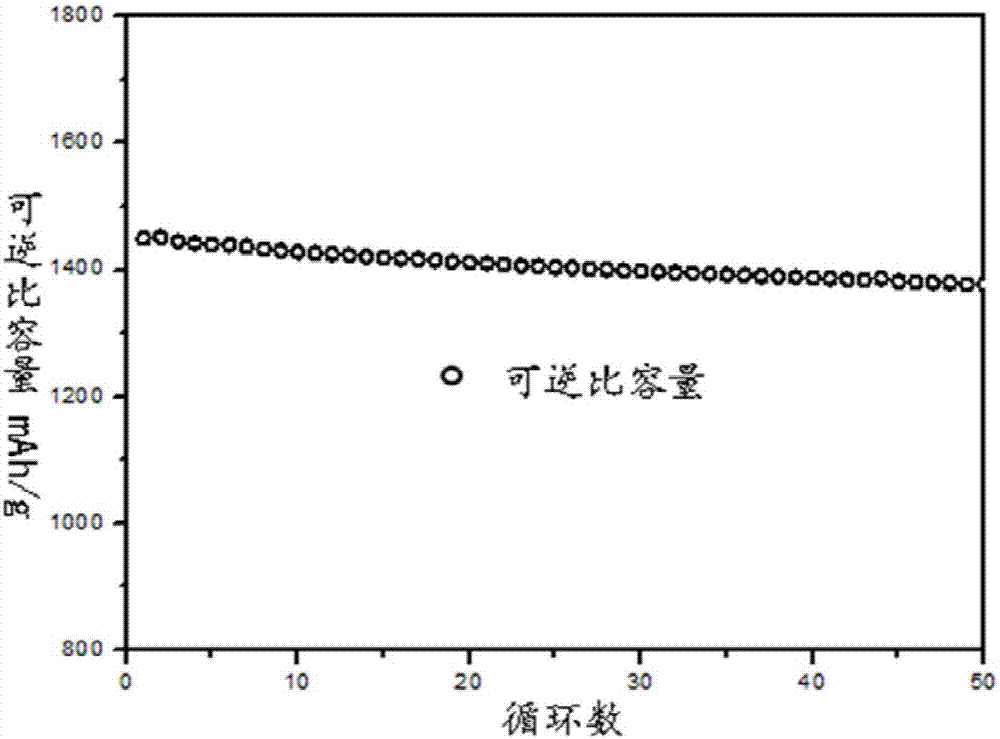

[0030] see figure 1 , the preparation method of novel structure graphene-coated silicon nanoparticles adopts the following preparation steps:

[0031] Material preparation: Take bulk commercial silicon and 6mm grinding balls, mix them at a ball-to-material ratio of 15:1, ball mill for 7 hours at a speed of 400r / min, sieve out the powder and use a Malvern 3000 laser particle size analysis The particle size range of the material tested by the instrument is obtained through testing. The particle size of the prepared silicon powder is in the range of 0.5-20.0um.

[0032] Step 1. Surface oxidation: Put the prepared silicon powder into a quartz crucible and put it into a high-temperature furnace. After gradually raising the temperature to 900°C, start to introduce compressed air and keep it warm for 1 hour. After cooling, the surface oxidized silicon powder is obtained. The oxygen content was tested by heating inert gas fusion-infrared absorption method, and the oxygen content was ...

Embodiment 2

[0041] The material preparation conditions are as in Example 1, the difference is that the silicon powder used is obtained by ball milling for 4 hours, and the particle size range of the material is tested using a Malvern 3000 laser particle size analyzer. The obtained silicon powder has a particle size of 0.6 -50um range.

[0042] The same method as in Example 1 was used to perform electrochemical tests and compare the volume expansion effect of the materials.

Embodiment 3

[0044] The material preparation conditions are the same as in Example 1, except that the oxidation time of the silicon powder is 0.5 h, and the oxygen content is 28.3% as measured by the pulse heating inert gas melting-infrared absorption method.

[0045] The same method as in Example 1 was used to perform electrochemical tests and compare the volume expansion effect of the materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com