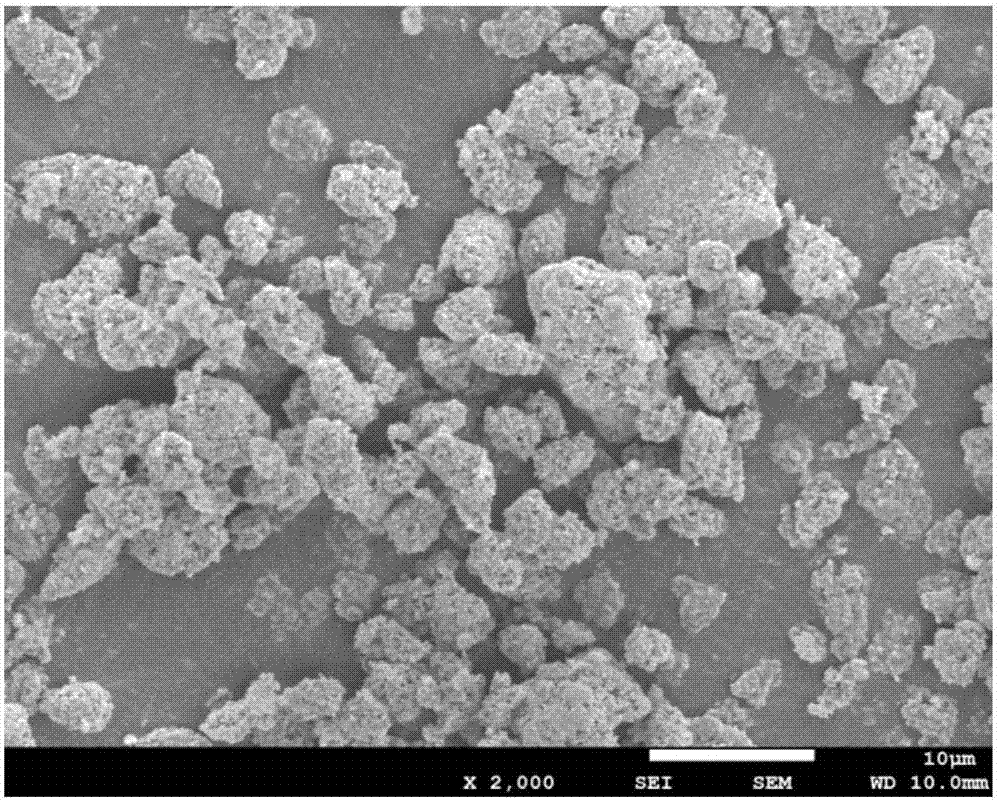

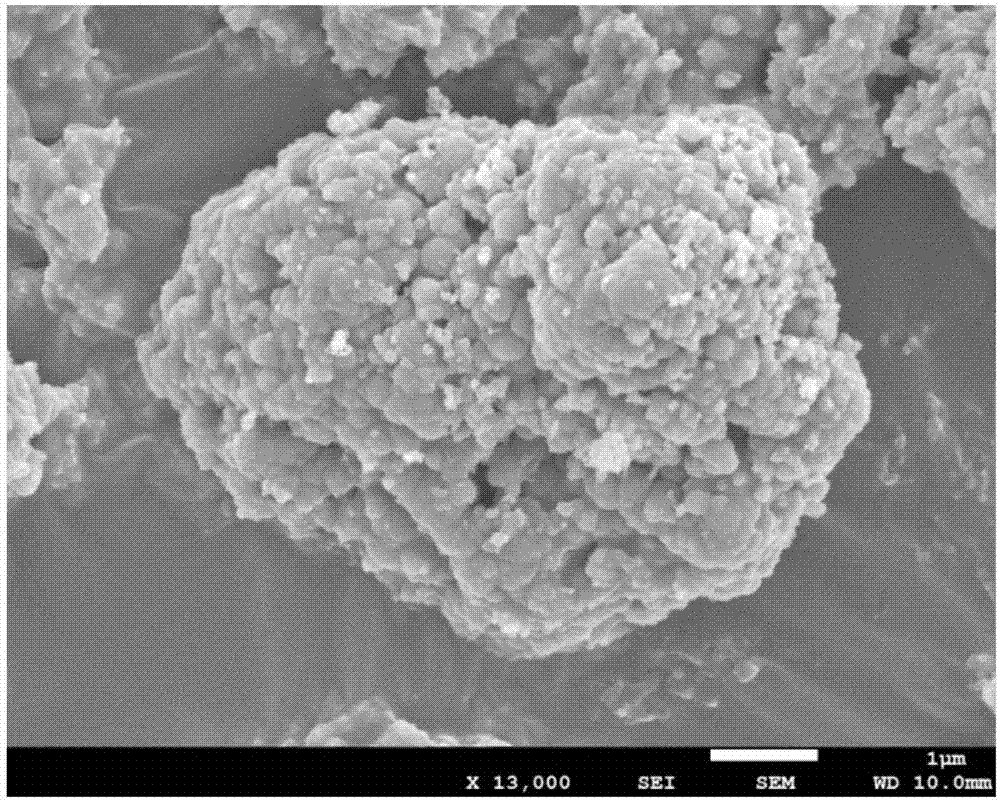

Preparation method for nano-micro structured ferric phosphate

A technology of iron orthophosphate and phosphoric acid solution, applied in structural parts, chemical instruments and methods, nanotechnology, etc., can solve the problems of different sizes of iron phosphate particles, difficult to control the size and morphology effectively, and achieve uniform size. control, excellent electrochemical performance, and the effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) be that ferrous sulfate and phosphoric acid that mol ratio is 1:1 are dissolved in water, stir, make ferrous ion concentration and be the mixed solution of 4mol / L; Be that the phosphoric acid solution of 1.5 is transferred in the reactor by pH, Add the mixed solution of ferrous sulfate and phosphoric acid, 2mol / L hydrogen peroxide solution and 2mol / L ammonia water into the phosphoric acid solution at the same time, the molar ratio of the added ferrous ion and hydrogen peroxide is 2:1, and the pH is controlled The reaction was carried out at 1.5, and the reaction was carried out at 25°C for 12 hours. After the reaction was complete, the aging was continued for 24 hours;

[0057] (2) The product obtained in step (1) is filtered, washed, and dried to obtain FePO 4 Hydrate precursor;

[0058] (3) Put the precursor obtained in step (2) in a muffle furnace and heat-treat at 600°C for 4 hours to obtain FePO 4 Material.

[0059] FePO prepared in this embodiment 4 Materi...

Embodiment 2

[0061] (1) Dissolve ferrous oxalate and ammonium dihydrogen phosphate with a molar ratio of 2:1 in a solution of water and ethanol, wherein the ethanol content is 5%, stir evenly, and make a mixed ferrous ion concentration of 3mol / L solution; the phosphoric acid solution with a pH of 1.9 is transferred to the reactor, and the mixed solution of ferrous oxalate and ammonium dihydrogen phosphate, 2mol / L of sodium hypochlorite and 3mol / L of ammonia are added to the phosphoric acid solution at the same time, and the added ferrous ions The molar ratio with sodium hypochlorite is 2:3, and the pH is controlled at 1.9 for the reaction, and the reaction is carried out at 35° C. for 25 hours. After the reaction is complete, continue aging for 10 hours;

[0062] (2) The product obtained in step (1) is filtered, washed, and dried to obtain FePO 4 Hydrate precursor;

[0063] (3) Put the precursor obtained in step (2) in a muffle furnace and heat-treat it at 700°C for 2 hours to obtain FeP...

Embodiment 3

[0066] (1) Dissolve the combination of ferrous oxalate and ferrous sulfate and phosphoric acid in the solution of water and ethanol according to the molar ratio of 2:3, wherein the ethanol content is 10%, and stir evenly to make the ferrous ion concentration 2mol / L The mixed solution; the phosphoric acid solution with a pH of 2.5 is transferred to the reactor, and the mixed solution of ferrous oxalate, ferrous sulfate and phosphoric acid, 2mol / L hydrogen peroxide solution and 2.5mol / L potassium hydroxide solution are simultaneously Add it into the phosphoric acid solution, the molar ratio of the added ferrous ion and hydrogen peroxide is 1:1, control the pH at 2.5 for the reaction, the reaction is carried out at 50°C for 4 hours, after the reaction is complete, continue to age for 20 hours;

[0067] (2) The product obtained in step (1) is filtered, washed, and dried to obtain FePO 4 Hydrate precursor;

[0068] (3) Put the precursor obtained in step (2) in a muffle furnace and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com