Preparation method for selenide thin film modifying foamed nickel electrode and application thereof

A foamed nickel and selenide technology, applied in the field of environmental engineering, can solve the problems of reduced catalytic anode oxygen precipitation activity, limited number of active sites, difficult industrial production, etc., achieves excellent electrocatalytic activity, reduces bubble overpotential, and the preparation process mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the method for preparing cobalt selenide film by foam nickel electrode

[0041] (1) Sonicate the nickel foam electrode in hydrochloric acid solution and absolute ethanol solution with a concentration of 6M for 15-25min respectively; dry it after cleaning and set aside;

[0042] (2) the nickel foam electrode that step (1) is obtained is placed in electrodeposition solution, comprises following component in the described electrodeposition solution: the potassium chloride of the cobalt chloride hexahydrate of 10mM, the selenium dioxide of 10mM and 50mM . The molar concentration ratio of described cobalt chloride hexahydrate and selenium dioxide is 1:1; Platinum rod is made counter electrode, and saturated calomel electrode is reference electrode, carries out constant potential deposition 20min under the potential of-0.6V under room temperature, super Fully rinse with pure water, blow dry with nitrogen, and dry overnight in a vacuum oven at 50°C to obtain a c...

Embodiment 2

[0046] Embodiment 2: the method for preparing cobalt selenide thin film by foam nickel electrode

[0047] The difference from Example 1 is that the potentiostatic deposition was carried out at room temperature at a potential of -0.7 V (relative to a saturated calomel reference electrode) for 20 min.

Embodiment 3

[0048] Embodiment 3: adopt the method for preparing cobalt selenide thin film with nickel foam electrode

[0049] The difference from Example 1 is that the potentiostatic deposition was carried out at room temperature at a potential of -0.8 V (relative to a saturated calomel reference electrode) for 20 min.

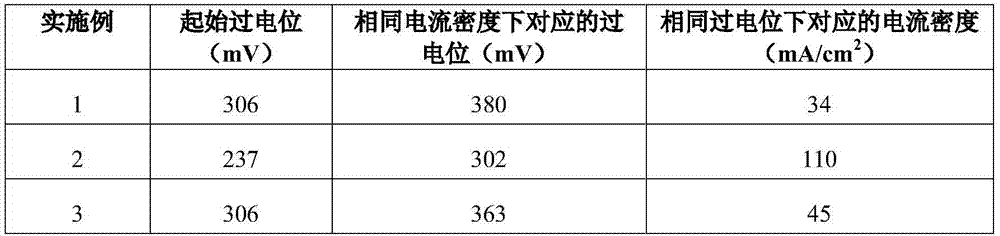

[0050] Table 1 Example 1-3 prepared cobalt selenide film property comparison (without calcination)

[0051]

[0052] Note: same current density: current density 30mA / cm 2 ; The same overpotential: 386mV.

[0053] According to Table 1, when the deposition potential is -0.7V (relative to the saturated calomel reference electrode), the cobalt selenide film prepared by direct deposition at room temperature without heating and calcining has the best properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com