Low-gloss bending-resistant heat transfer printing powder coating used for section aluminum and a preparing method thereof

A powder coating, low-gloss technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as unsatisfactory, low gloss, mechanical properties of coating films, and decreased storage stability of weather-resistant powder coatings, so as to avoid Effects of residual paper printing, reducing gloss, and improving transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare the low-gloss anti-bending heat-transfer powder coating for aluminum profile according to the following steps:

[0036] (1) According to the following component A formula, put the raw materials into the mixing tank according to their corresponding mass percentages for pre-mixing, and the time is 3-4 minutes;

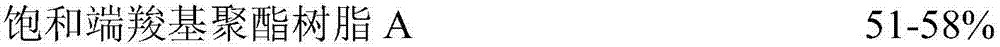

[0037] A component:

[0038]

[0039] Wherein, the saturated carboxyl-terminated polyester resin A is a high-toughness carboxyl polyester resin with an acid value of 46 mgKOH / g, a viscosity of 7500 mPa·s at 200°C, and a glass transition temperature of 67°C; The median particle size of extinction barium is 5.8μm;

[0040] (2) Use a twin-screw extruder to melt, knead, and disperse the premixed raw materials evenly and extrude them. The frequency of the screw is 30Hz; then tableting and crushing;

[0041] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40 Hz, and the frequency of the auxiliary mill is 3...

Embodiment 2

[0056] Prepare the low-gloss anti-bending heat-transfer powder coating for aluminum profile according to the following steps:

[0057] (1) According to the following component A formula, put the raw materials into the mixing tank according to their corresponding mass percentages for pre-mixing, and the time is 3-4 minutes;

[0058] A component:

[0059]

[0060]Wherein, the saturated carboxyl-terminated polyester resin A is a high-toughness carboxyl polyester resin with an acid value of 47mgKOH / g, a viscosity of 7700mPa·s at 200°C, and a glass transition temperature of 67°C; The median particle size of extinction barium is 5.7μm;

[0061] (2) Use a twin-screw extruder to melt, knead, and disperse the premixed raw materials evenly and extrude them. The output screw frequency is 33Hz; then perform tableting and crushing;

[0062] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 45Hz, and the frequency of the auxiliary mill ...

Embodiment 3

[0076] Prepare the low-gloss anti-bending heat-transfer powder coating for aluminum profile according to the following steps:

[0077] (1) According to the following component A formula, put the raw materials into the mixing tank according to their corresponding mass percentages for pre-mixing, and the time is 3-4 minutes;

[0078] A component:

[0079]

[0080]

[0081] Wherein, the saturated carboxyl-terminated polyester resin A is a high-toughness carboxyl polyester resin with an acid value of 50 mgKOH / g, a viscosity of 7800 mPa·s at 200°C, and a glass transition temperature of 67°C; The median particle size of extinction barium is 5.5μm;

[0082] (2) Use a twin-screw extruder to melt, knead, and disperse the premixed raw materials evenly and extrude them. The frequency of the screw is 40Hz; then tableting and crushing;

[0083] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40Hz, and the frequency of the auxiliar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com