A method of preparing fucoidan having an efficiently customized molecular weight and applications of the fucoidan

A technology for fucoidan and molecular brown algae, which is applied in the directions of pharmaceutical formulations, organic active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of restricting the progress of research and market development of fucoidan, unclear structure, complex ingredients, etc. , to achieve significant blood lipid lowering effect, reduce impurity components, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

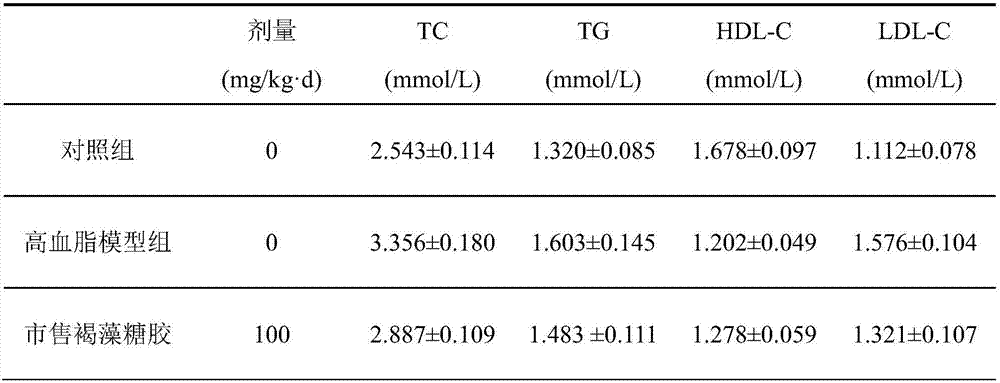

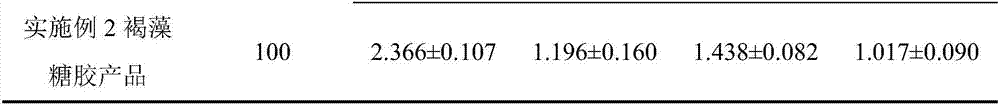

Examples

Embodiment 1

[0039] The specific production process steps of a high-efficiency high-purity uniform low-molecular-weight fucoidan product are as follows:

[0040] (1) Raw material: solid fucoidan product extracted from kelp, the specific method is as follows:

[0041] Take kelp and pulverize it so that the ratio of material to liquid is 1:15-20, bathe in 90°C water for 4 hours, and after centrifugation, take the supernatant and precipitate it with 20% (w / v) calcium chloride solution for 30 minutes, centrifuge, and use the volume of the supernatant The ethanol solution with a fraction of 70-80% was precipitated, then centrifuged and dried to obtain crude fucoidan. It is prepared into a solution according to a mass concentration of 3% (w / v);

[0042] (2) Microwave forced dissolution, microwave frequency at 1500MHz, 4 times of treatment, 5min interval, 8s each time;

[0043] (3) Ultrasonic degradation, the fucoidan solution completely dissolved in step (2) is subjected to ultrasonic treatmen...

Embodiment 2

[0049] The specific production process steps of a high-efficiency high-purity uniform low-molecular-weight fucoidan product are as follows:

[0050] (1) Raw materials: the solid fucoidan product extracted from kelp, which is derived from the crude fucoidan prepared in step (9) of Example 1 in the patent CN106008730A, with a mass concentration of 4% (w / v) prepared as a solution;

[0051] (2) Microwave forced dissolution, microwave frequency at 1000MHz, 5 times of treatment, interval 5min, 10s each time;

[0052] (3) Ultrasonic degradation, the fucoidan solution completely dissolved in step (2) is subjected to ultrasonic treatment to reduce the molecular weight of macromolecular fucoidan, the ultrasonic frequency is 60KHz, and the treatment time is 20min;

[0053] (4) Fractionation of fucoidan, using a high-flow rate agarose gel chromatography (DEAE-Sepharose Fast Flow) classification system, using 0-1.5mol / L NaCl solution as the mobile phase for elution, and the flow rate of t...

Embodiment 3

[0059] The specific production process steps of a high-efficiency high-purity uniform low-molecular-weight fucoidan product are as follows:

[0060] (1) Raw materials: fucoidan solution extracted from kelp, the specific preparation method is as follows:

[0061] Take kelp and crush it, use 5-26g / L calcium chloride solution to make the ratio of solid to liquid 1:8-10, adjust the pH to 2, extract in a water bath at 50-60°C for 1-2 hours, and centrifuge to obtain the supernatant It is the fucoidan solution to be processed;

[0062] (2) Microwave forced dissolution, microwave frequency at 1000MHz, treatment 5 times, interval 5min, 5s each time; (3) Ultrasonic degradation, ultrasonic treatment of fucoidan solution completely dissolved in step (2) to reduce macromolecules For the molecular weight of fucoidan, the ultrasonic frequency is 45KHz, and the processing time is 30min;

[0063] (4) Fractionation of fucoidan, using a high-flow agarose gel chromatography (DEAE-Sepharose Fast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com