A KNN-based energy storage glass-ceramic material with ultra-low dielectric loss and its preparation method

A technology of ultra-low dielectric and glass-ceramics, which is applied in the field of glass-ceramic materials, can solve problems such as unpreparable and high breakdown field strength, and achieve fine internal grains, eliminate internal stress, and complete crystal growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the glass-ceramic material of the present embodiment comprises the following steps:

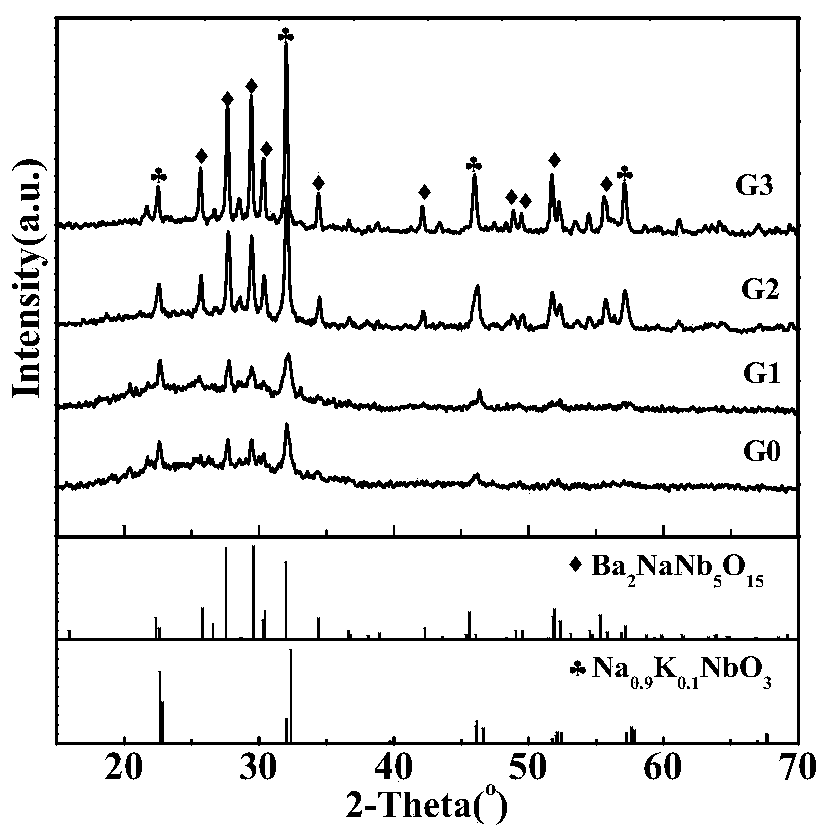

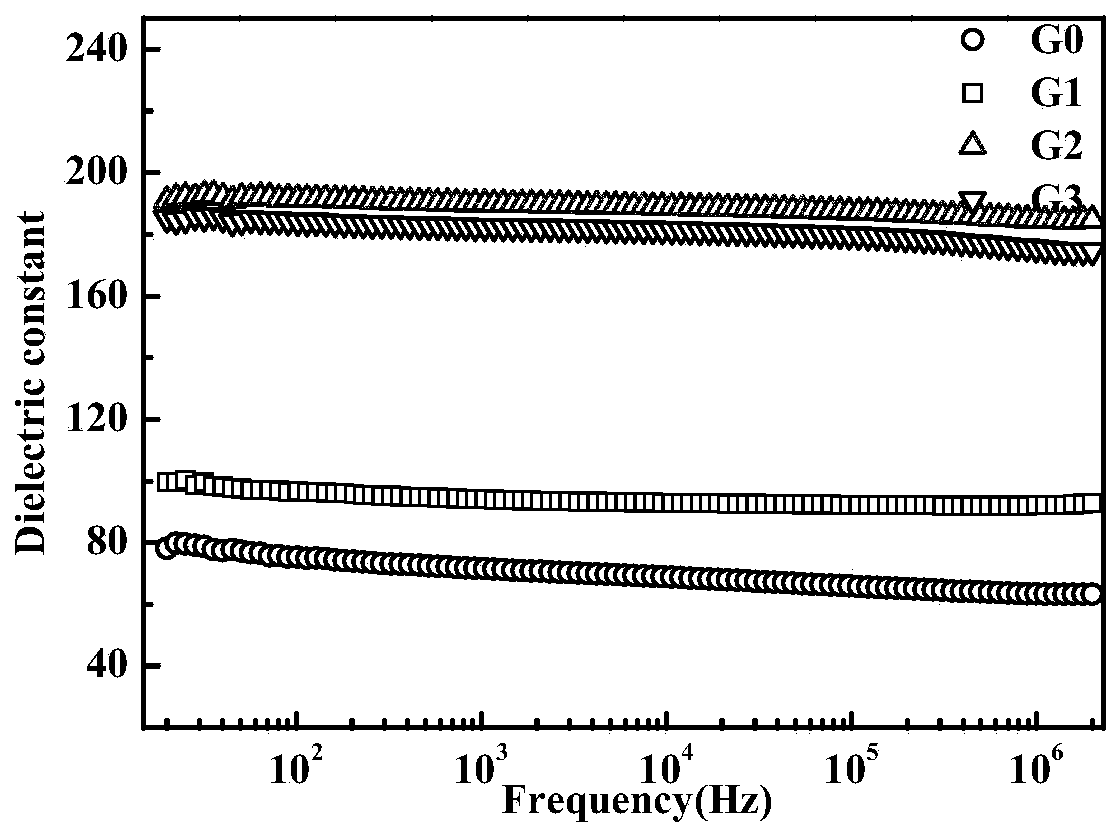

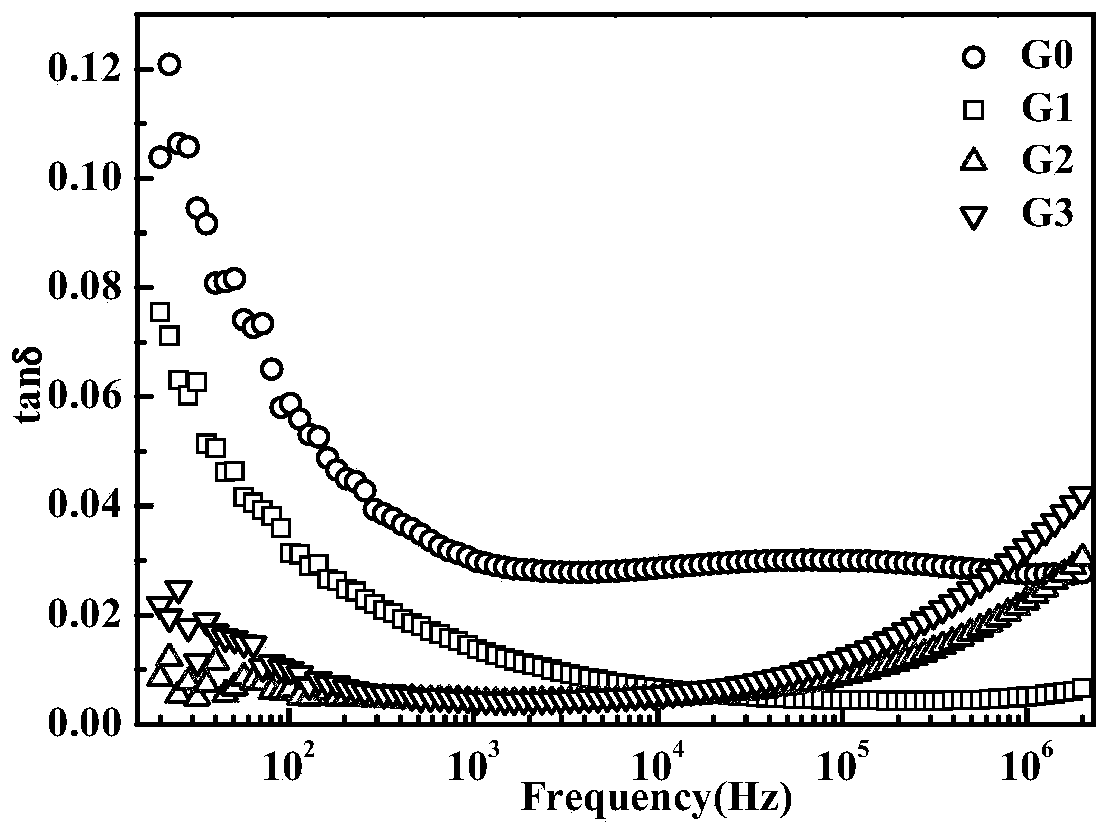

[0036] 1) The KNN-based glass-ceramic material in this embodiment is 0.25:0.25:0.6:0.1:0.6:0.2 by the amount of substance, and K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , BaCO 3 , SiO 2 , H 3 BO 3 and 0.2 mol% CeO 2 mix. At this time, in the crystal phase, K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 and BaCO 3 The molar ratio is (3-x): (3-x): 6: 2x, x = 0.5; SiO in the glass phase 2 and H 3 BO 3 The molar ratio is 3:1, and the glass phase accounts for 40% of the total crystal phase and glass phase.

[0037] 2) When heating the quartz crucible with the furnace from room temperature to 1100°C, start adding the mixture, then continue heating to 1350°C, and keep the temperature at 1350°C for 30 minutes to melt the mixture evenly to obtain a mixed molten material; put the mixed molten material on the copper plate After molding, put it into the furnace quickly and ann...

Embodiment 2

[0041] 1) The KNN-based glass-ceramic material in this embodiment is 0.2:0.2:0.6:0.2:0.6:0.2 by the amount of substance, get K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , BaCO 3 , SiO 2 , H 3 BO 3 and 0.2 mol% CeO 2 mix. At this time, in the crystal phase, K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 and BaCO 3 The molar ratio is (3-x): (3-x): 6: 2x, x = 1; SiO in the glass phase 2 and H 3 BO 3 The molar ratio is 3:1, and the glass phase accounts for 40% of the total crystal phase and glass phase.

[0042] 2) When heating the quartz crucible with the furnace from room temperature to 1100°C, start adding the mixture, then continue heating to 1350°C, and keep the temperature at 1350°C for 30 minutes to melt the mixture evenly to obtain a mixed molten material; put the mixed molten material on the copper plate After molding, put it into the furnace quickly and anneal at 650°C for 7 hours to obtain the annealed glass;

[0043] 3) After holding at 850°C for 5h, cool down to room tempera...

Embodiment 3

[0046] 1) The KNN-based glass-ceramic material in this embodiment is 0.15:0.15:0.6:0.3:0.6:0.2 by the amount of substance, and K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , BaCO 3 , SiO 2 , H 3 BO 3 and 0.2 mol% CeO 2 mix. At this time, in the crystal phase, K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 and BaCO 3 The molar ratio is (3-x): (3-x): 6: 2x, x = 1.5; SiO in the glass phase 2 and H 3 BO 3 The molar ratio is 3:1, and the glass phase accounts for 40% of the total crystal phase and glass phase.

[0047] 2) When heating the quartz crucible with the furnace from room temperature to 1100°C, start adding the mixture, then continue heating to 1350°C, and keep the temperature at 1350°C for 30 minutes to melt the mixture evenly to obtain a mixed molten material; put the mixed molten material on the copper plate After molding, put it into the furnace quickly and anneal at 600°C for 7 hours to obtain the annealed glass;

[0048] 3) After holding at 850°C for 5h, cool down to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com