Device for removing fine particles by combining acoustic agglomeration technology with turbulence coalescence technology and method thereof

A technology of fine particles and sound waves, which is applied in the field of devices for removing fine particles through sound wave agglomeration combined with turbulent flow agglomeration technology, can solve the problems of increasing energy consumption, increasing noise pollution, increasing sound pressure level, etc., to achieve improved removal efficiency, Effect of improving agglomeration efficiency and reducing sound pressure level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

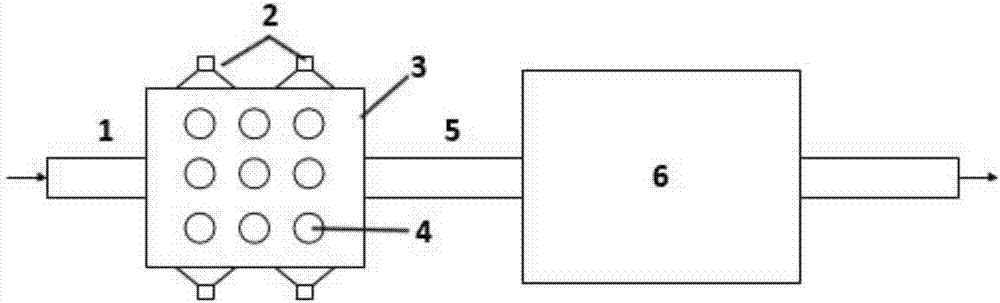

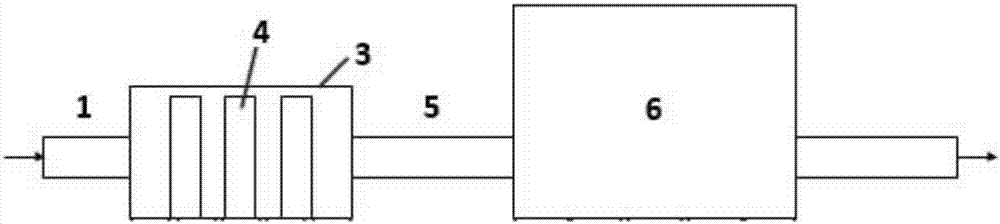

[0019] Such as figure 1 , figure 2 As shown, a device for removing fine particles by acoustic agglomeration combined with turbulent agglomeration technology includes an acoustic agglomeration chamber 3, a compression drive sound source 2, a turbulence cylinder 4, a flue gas inlet pipe 1 and a flue gas outlet pipe 5; The flue gas inlet pipe 1, the sound wave agglomeration chamber 3, the flue gas outlet pipe 5 and the dust collector 6 are connected in series in sequence; a single or multiple compression driving sound sources 2 are arranged on the external top surface of the sound wave agglomeration chamber 3; inside the sound wave agglomeration chamber 3 Disturbance cylinders 4 are arranged horizontally; the flow disturbance cylinders 4 are cylindrical and arranged in an array, and their function is to generate turbulent flow. The compression driving sound source 2 has a frequency of 1000-2000 Hz and a sound pressure level of 120-150 dB. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com