Printed circuit board pcb and its non-destructive testing method and device

A printed circuit board, non-destructive testing technology, used in printed circuit components, circuit inspection/identification, etc., can solve problems such as tight PCB layout area, signal quality degradation, signal distortion, etc., to save layout area and reduce test costs. , the effect of eliminating signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

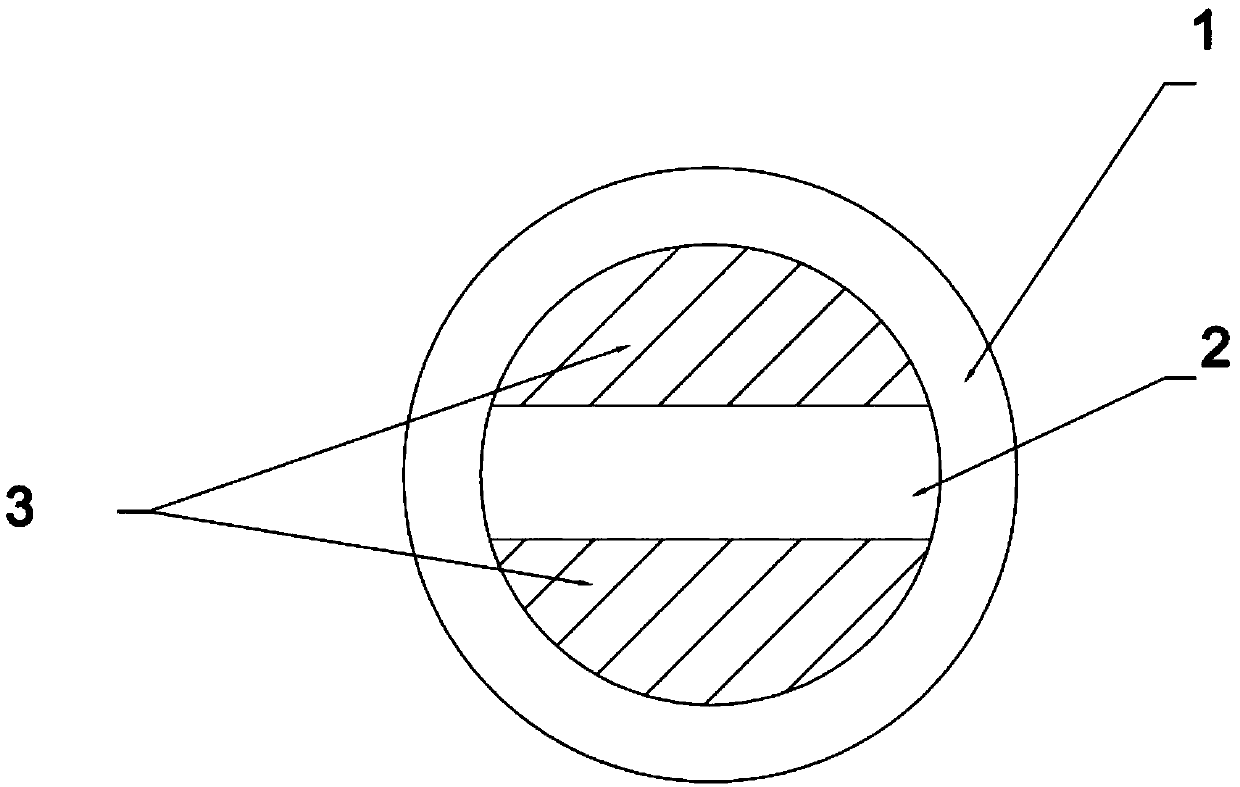

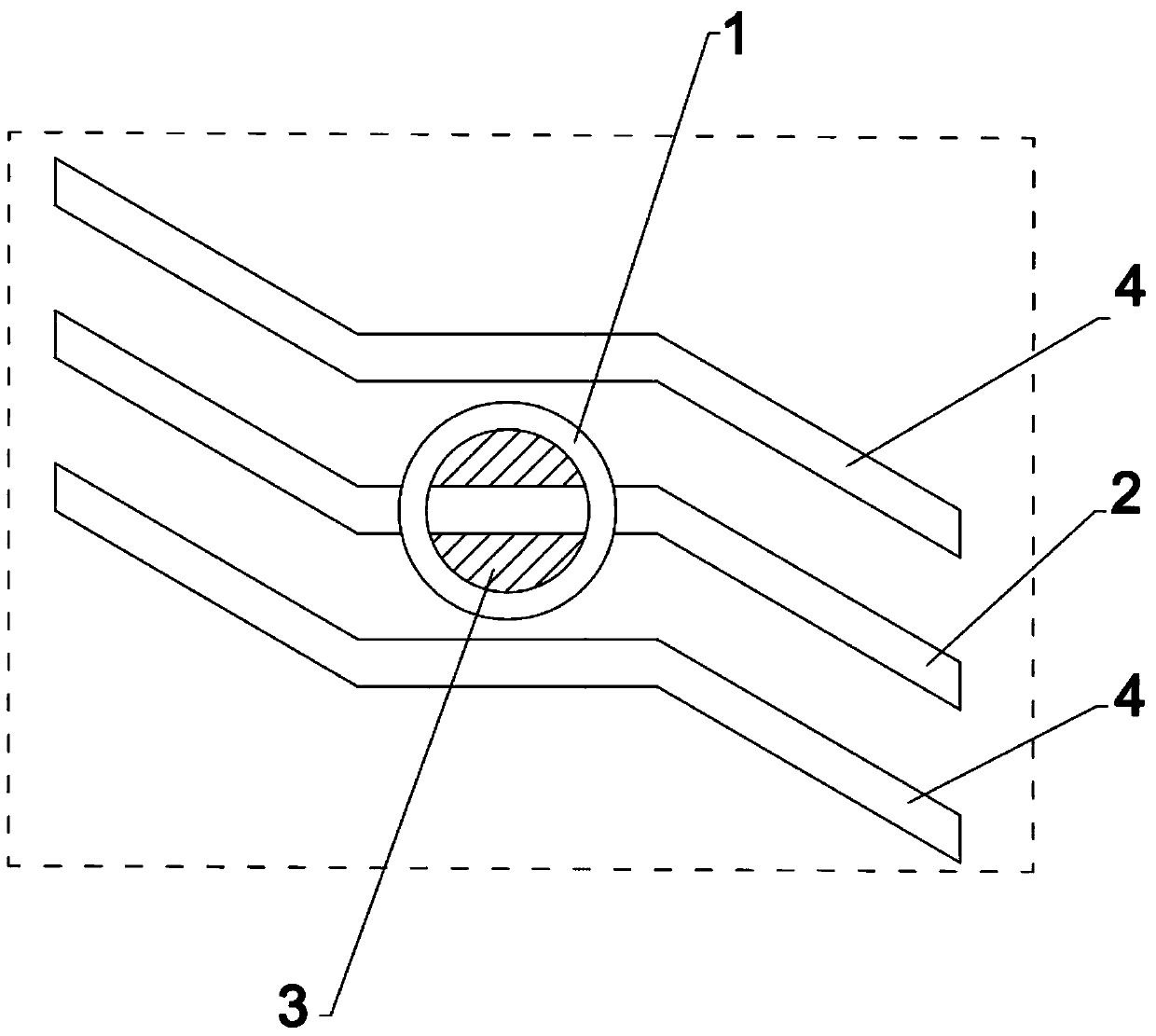

[0060] refer to figure 1 and figure 2 , the present invention proposes a printed circuit board (PCB). The solder resist on the surface of the PCB is solder resist cured by solvent-based ink. The position of the circuit 2 to be tested on the solder resist surface is provided with a raised silk screen ring 1, and the silk screen ring 1 is a non-solvent The silk screen ring 1 formed by solidifying ink, the inner circle of the silk screen ring 1 corresponds to the line 2 to be tested and the forbidden areas 3 distributed on both sides of the line 2 to be tested.

[0061] During PCB processing, the PCB is processed and produced according to the conventional PCB process, and the solder mask on the surface of the PCB is processed with solvent-based ink. After the solder mask is cured, the silk screen ring 1 on the surface of the PCB is processed with non-solvent ink. In the way of printing, since the ink of the silk screen ring 1 is printed on the upper layer of the cured solder ma...

Embodiment 2

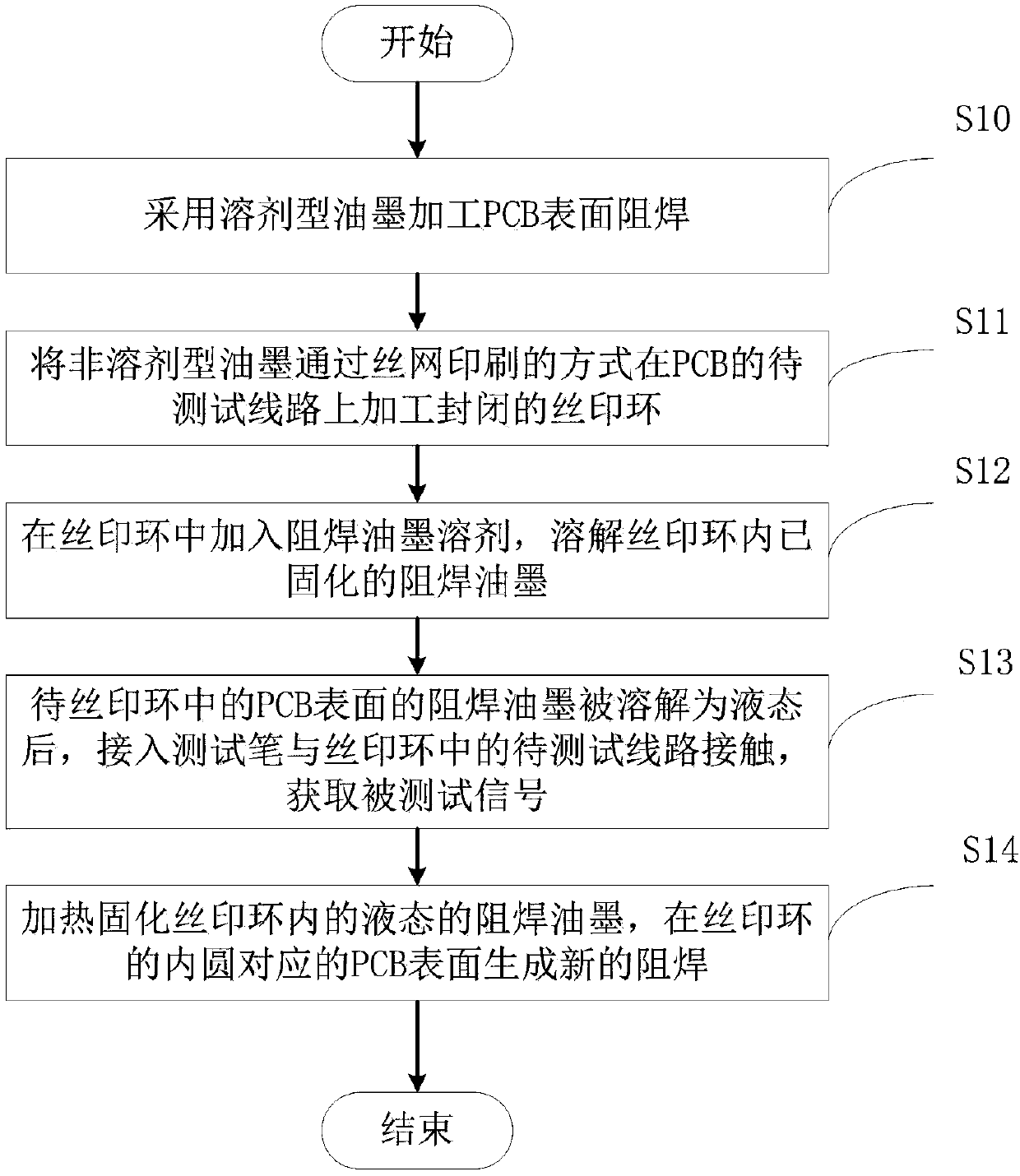

[0065] refer to image 3 , the present invention also proposes a method for non-destructive testing of the printed circuit board PCB as described in Embodiment 1, comprising the following steps:

[0066] S10, using solvent-based ink to process the solder mask on the surface of the PCB.

[0067] S11. Process a closed silk-screen ring on the circuit 2 to be tested on the PCB by screen-printing non-solvent ink.

[0068] S12 , adding a solder resist ink solvent into the silk screen printing ring 1 to dissolve the cured solder resist ink in the silk screen printing ring 1 .

[0069] S13. After the solder resist ink on the surface of the PCB in the silk screen ring 1 is dissolved into a liquid state, a test pen is connected to contact the circuit 2 to be tested in the silk screen ring 1 to obtain a signal to be tested.

[0070] S14 , heat and solidify the liquid solder resist ink in the silk screen ring 1 , and generate new solder resist on the surface of the PCB corresponding to ...

Embodiment 3

[0094] refer to Figure 5 , the present invention also proposes a device for non-destructive testing of the printed circuit board PCB described in Embodiment 1, including:

[0095] The solder resist processing unit 10 is used for processing the solder resist on the surface of the PCB with solvent-based ink.

[0096] The silk screen ring processing unit 20 is used to process the closed silk screen ring 1 on the circuit 2 to be tested on the PCB by screen printing with non-solvent ink.

[0097]A marking unit 30 is provided for setting a signal marking silk screen around the silk screen ring 1 for identifying the circuit 2 to be tested.

[0098] The positioning unit 40 is used to determine the position of the silk screen ring 1 according to the signal mark silk screen, and determine the specific position of the corresponding circuit 2 to be tested.

[0099] The dissolving unit 50 is used to add a solder resist ink solvent into the silk screen printing ring 1 to dissolve the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com