Preparation method of silicon-carbon composite material

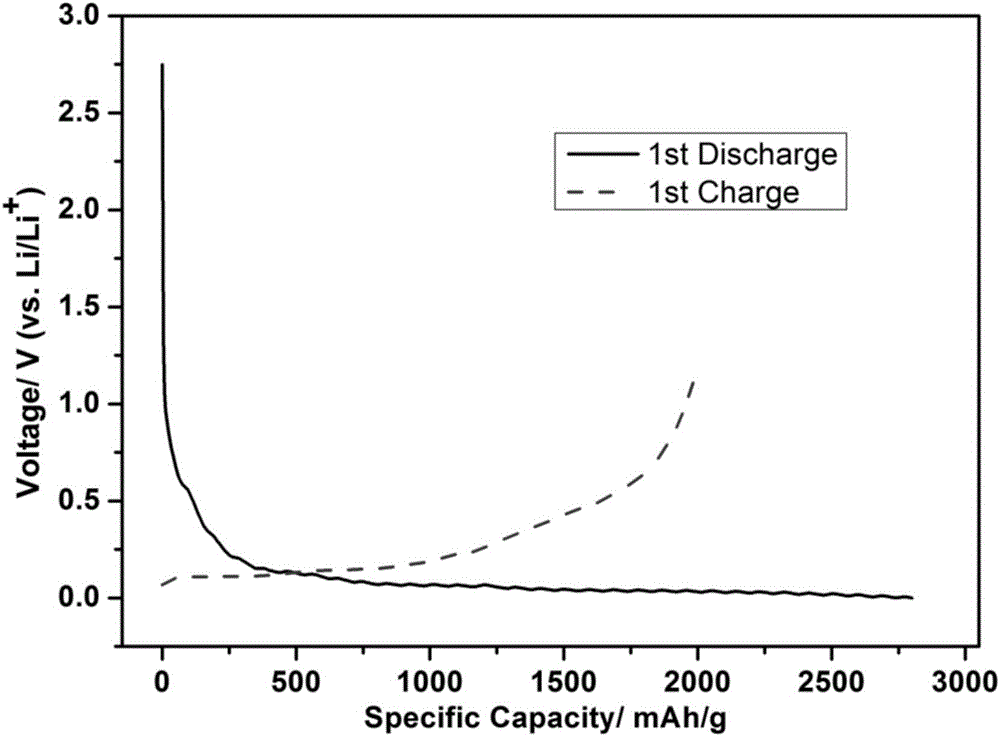

A silicon-carbon composite material and carbon source technology, which is applied in the preparation of microspheres, electrode manufacturing, and microcapsule preparations, can solve the problems of poor cycle performance of lithium batteries, consumption of lithium ions, and detachment between battery electrode active materials and current collectors. , to achieve good charge and discharge performance and cycle performance, improve electrochemical performance, and facilitate rapid deintercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0031] Step 1: preparing carbon-coated nano silicon-based oxide.

[0032] ① Weigh a certain amount of aqueous solution of silicon particles and carbon source and mix them uniformly to form a suspension with a silicon-carbon molar ratio of 5-15:1;

[0033] ②Transfer to a container, perform a hydrothermal reaction at a first preset temperature for a first preset time, then cool to room temperature, take it out, wash with water and absolute ethanol, and then vacuum dry to prepare a carbon-coated nano-silicon-based oxide.

[0034] Step 2: preparing a silicon-carbon composite material.

[0035] ① Grinding and mixing the carbon-coated nano-silicon-based oxide obtained in step 1 with metal magnesium powder at a mass ratio of 1:0.6-1.6 to form a mixture, and then mixing the mixture into the inorganic salt;

[0036] ②Put the above-mixed mixture and inorganic sal...

Embodiment 1

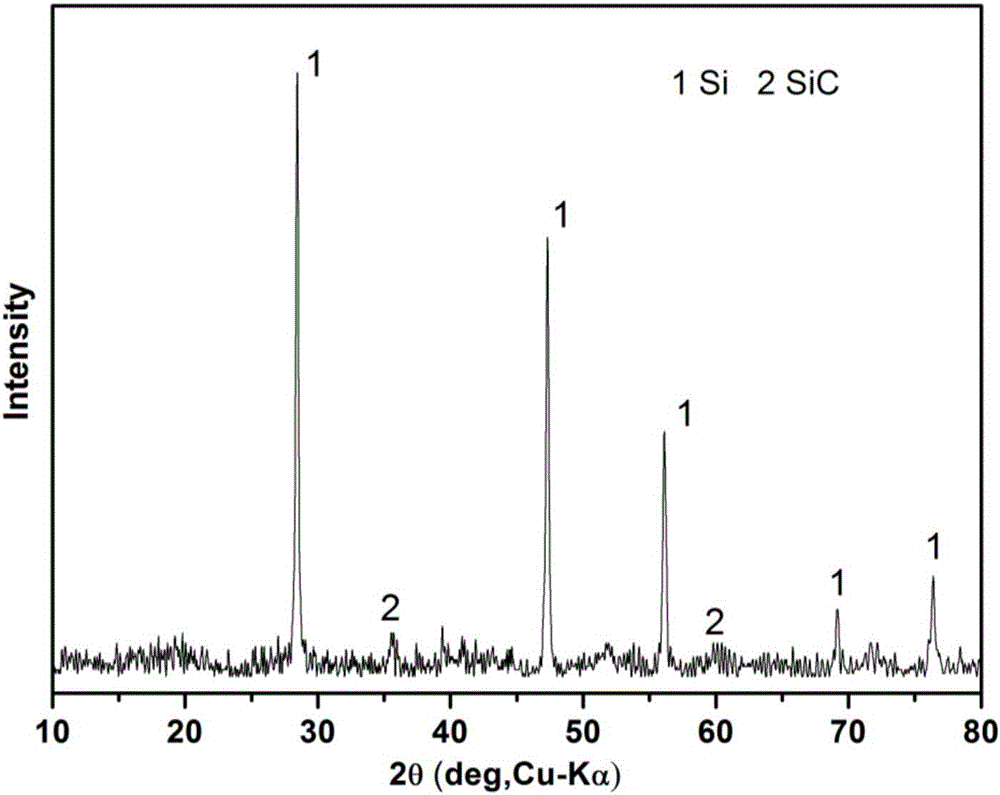

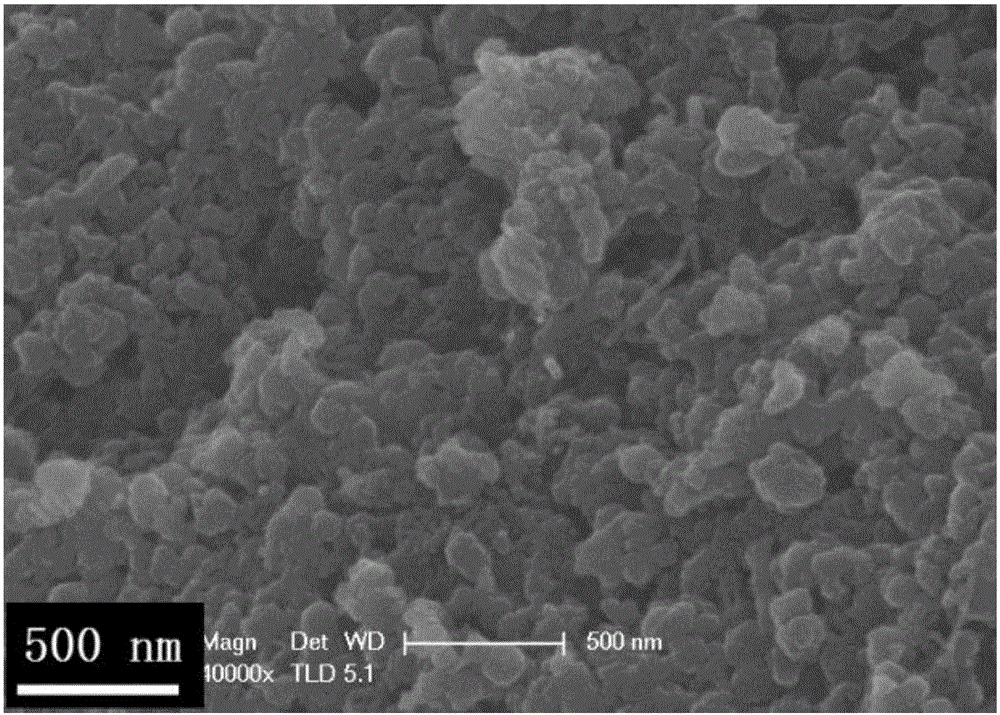

[0046] ① Weigh 5.00g of SiO 2 Stir and disperse the granules in 40mL deionized water, add 1.51g of glucose granule hydrate, stir and mix evenly, transfer to a 50mL container, perform a hydrothermal reaction at 180°C for 4h, then cool to room temperature, take it out, wash with water, and dry in vacuum to prepare carbon-coated SiO 2 ;

[0047] ② Grind and mix carbon-coated nano silicon-based oxide and metal magnesium powder at a mass ratio of 1:0.88 to form a mixture, and then mix the mixture into a mixed inorganic salt of anhydrous sodium chloride and anhydrous potassium chloride (1: 1 wt%), the mass ratio of the carbon-coated nano-silicon carbon-based oxide, metal magnesium powder and mixed inorganic salt is 1:0.88:20, then put the mixed mixture and inorganic salt into the container, and place In an inert gas, raise the temperature to 700°C at a heating rate of 3°C / min, keep it for 10 hours, take it out after cooling, and wash it with a certain amount of hydrochloric acid, ...

Embodiment 2

[0049] ① Weigh 5.00g of SiO 2 Stir and disperse the particles in 40mL of deionized water, add 1.70g of glucose granule hydrate, stir and mix evenly, transfer to a 50mL container, perform a hydrothermal reaction at 190°C for 6h, then cool to room temperature, take it out, wash with water, and dry in vacuum to prepare Carbon-coated nano-SiO 2 ;

[0050] ② Carbon-coated nano-SiO 2and metal magnesium powder are ground and mixed in a mass ratio of 1:0.84 to form a mixture, and then the mixture is mixed into a mixed inorganic salt of anhydrous sodium chloride and anhydrous magnesium chloride (1:1.23wt%), and the carbon-coated nano The mass ratio of silicon carbon-based oxide, metal magnesium powder and mixed inorganic salt is 1:0.84:20, then put the mixed mixture and inorganic salt into a container, and place it in an inert gas, at 3°C / min Rise to 650°C at a certain heating rate, keep it for 8 hours, take it out after cooling, wash it with a certain amount of hydrochloric acid, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com