Method for extracting germanium from high-silicon high-iron low-grade germanium-containing material

A low-grade, high-speed iron technology, applied in the direction of improving process efficiency, can solve problems such as low leaching rate, equipment corrosion, and low recovery rate, and achieve the effects of accelerating diffusion speed, increasing contact probability, and improving reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

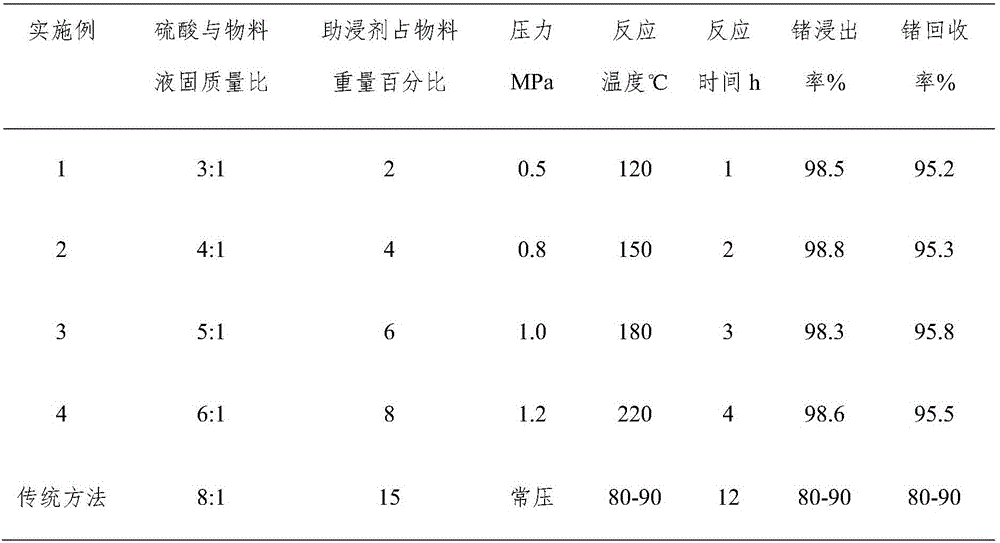

Examples

Embodiment 1

[0029] (1) After mixing the high-silicon, high-iron and low-grade germanium-containing materials with 50g / L sulfuric acid and immersion aid, add them to the high-pressure reaction kettle, control the temperature at 120°C, feed oxygen-containing gas, adjust the oxygen partial pressure to 0.5MPa, and carry out Oxygen pressure acid leaching, the material is discharged after 1 hour of reaction, and the obtained material is separated from solid and liquid to obtain a germanic acid immersion solution;

[0030] (2) adding reductant iron powder earlier in the germanium-containing acid immersion solution that step (1) obtains iron ion is reduced to ferrous ion, then adds gelatin desiliconization in the solution after reduction, obtains after removing iron and desilicon purification solution;

[0031] (3) add stabilizer in the purification solution that step (2) obtains, adopt germanium extractant to extract germanium or adopt tannic acid to precipitate germanium, obtain extracting germ...

Embodiment 2

[0033] (1) After mixing the high-silicon, high-iron and low-grade germanium-containing materials with 150g / L sulfuric acid and immersion aid, add them to the high-pressure reactor, control the temperature at 220°C, feed oxygen-containing gas, adjust the oxygen partial pressure to 1.2MPa, and carry out Oxygen pressure acid leaching, the material is discharged after 4 hours of reaction, and the obtained material is separated from solid and liquid to obtain a germanic acid immersion solution;

[0034] (2) adding reductant iron powder earlier in the germanium-containing acid immersion solution that step (1) obtains iron ion is reduced to ferrous ion, then adds gelatin desiliconization in the solution after reduction, obtains after removing iron and desilicon purification solution;

[0035] (3) add stabilizer in the purification solution that step (2) obtains, adopt germanium extractant to extract germanium or adopt tannic acid to precipitate germanium, obtain extracting germanium ...

Embodiment 3

[0037] (1) After mixing the high-silicon, high-iron and low-grade germanium-containing materials with 100g / L sulfuric acid and leaching aid, add them to the high-pressure reactor, control the temperature at 180°C, feed oxygen-containing gas, adjust the oxygen partial pressure to 0.8MPa, and carry out Oxygen pressure acid leaching, the material is discharged after 3 hours of reaction, and the obtained material is separated from solid and liquid to obtain a germanic acid immersion solution;

[0038] (2) adding reductant iron powder earlier in the germanium-containing acid immersion solution that step (1) obtains iron ion is reduced to ferrous ion, then adds gelatin desiliconization in the solution after reduction, obtains after removing iron and desilicon purification solution;

[0039] (3) add stabilizer in the purification solution that step (2) obtains, adopt germanium extractant to extract germanium or adopt tannic acid to precipitate germanium, obtain extracting germanium r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com