Dry distillation carbonizing treatment system for urban and rural lightweight wastes

A technology of carbonization treatment and waste, applied in the direction of gas treatment, special dry distillation, chemical instruments and methods, etc., can solve the problem that thermal carbide and ash cannot be fully utilized, can not handle urban and rural light waste well, and is harmless The low efficiency of recycling and resource utilization can achieve the effect of improving harmlessness and resource utilization, simple structure and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

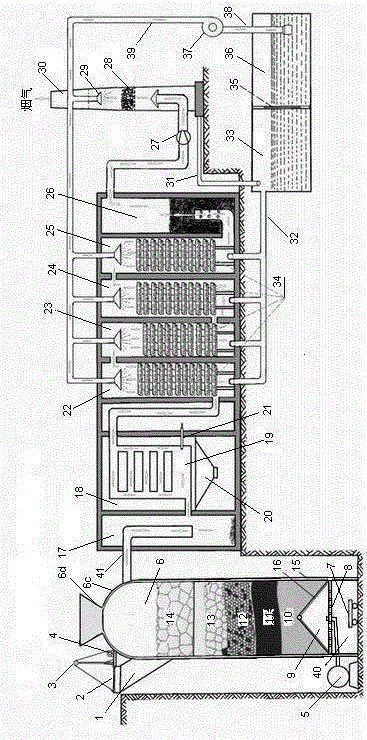

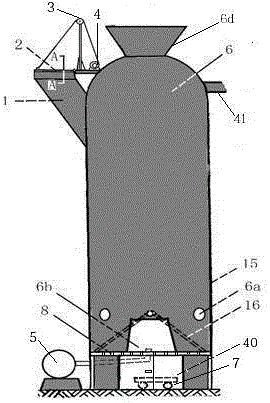

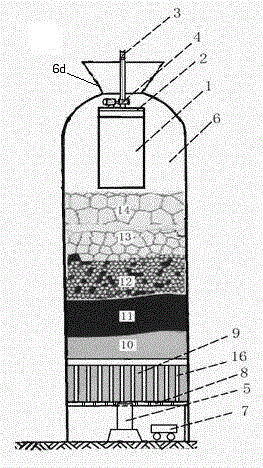

[0044] Such as figure 1 - Figure 7 As shown, the dry distillation carbonization kiln device includes a kiln body 15, a kiln roof 6c, a kiln cover 6d, a kiln bridge 8, a supporting kiln bridge 16, a kiln chamber 9, a kiln door 6b, a waste feeding bin 1, and a feed port cover plate 2. Hoist 4, air channel 40 and flue 41; the inner wall of the kiln body 15 is made of refractory bricks, and the outer wall is made of red bricks, and a steel and cement ring beam is built every 2 to 4 meters from the bottom up; The kiln bridge 8 is set above the air channel 40 below the inside of the kiln body 15. It is welded by a plurality of steel bars arranged at intervals, and is installed in the kiln chamber 9 with a horizontal inclination of 15 degrees from the direction of the kiln door 6b. The upper part of the kiln chamber 9 is A supporting kiln bridge 16 for supporting waste; the waste feeding bin 1 is arranged above the outer wall of the kiln body 15, and a feed inlet cover plate 2 is a...

Embodiment 2

[0058] Such as figure 1 , Figure 8 As shown, the dust removal and purification device includes a gravity dust removal chamber 17, a material drying bin 18, a harmful gas gas combustion chamber 19, a hopper under the drying bin 20, a gas burner 21, a primary spray chamber 22, and a secondary spray chamber 23. Three-stage spray chamber 24, four-stage spray chamber 25, harmful gas treatment chamber 26, pressurizer 27, deodorizing layer 28, spraying nozzle 29, chimney 30; 6 The flue 41 of the kiln roof 6d is connected, and a channel is provided on the left side wall to communicate with the material drying bin 18; the material drying bin 18 is provided with a harmful gas combustion chamber 19, and the upper part is composed of a plurality of communicating heat dissipation pipes. Drying materials are placed around, and the lower part is the lower hopper 20; the heat dissipation pipe in the material drying bin 18 is connected to the lower side pipeline on the left wall of the first...

Embodiment 3

[0063] Such as figure 1 As shown, the waste water circulation treatment device includes waste water discharge pipes 31, 32, waste water settling tank 33, filter screen 35, filter pool 36, water pump 37, water pump lower water pipe 38, water pump upper water pipe 39; The upper port of the drain pipe 31 is connected to the waste water discharge port of the chimney base, and the waste water discharge port at the lower end is communicated with the waste water sedimentation tank 33; the waste water discharge pipe 32 is respectively provided with one, two, three, and four spray chambers communicated with each other. Pipeline, waste water discharge outlet is communicated with waste water settling tank 33; Filter screen 35 is arranged between waste water settling tank 33 and filter tank 36; The lower end of described suction pump water pipe 38 leads into waste water settling tank 33, and the upper end connects water pump 37; The upper water pipe 39 of the water pump communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com