A kind of water-based binder for positive electrode of lithium ion battery and preparation method thereof

A water-based binder, lithium-ion battery technology, applied in battery electrodes, binder types, ester copolymer binders, etc., can solve the problems of low positive electrode bulk density, low production efficiency, low yield, etc. The effect of good battery cycle performance, improved yield and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this example, sodium acrylamido isopropyl sulfonate, laurate and sodium persulfate are used as amphiphilic reactive emulsifiers, functional monomers with special functional groups that improve the flexibility of polymer chains, and initiators, respectively. The mixture of acrylic acid, acrylamide and butyl acrylate is used as the acrylate monomer, and the ratio of the acrylate monomer, the amphiphilic reactive emulsifier and the functional monomer in the whole preparation process is: 19:0.1:1.

[0032]Specifically prepare the solution of lithium-ion battery cathode water-based binder according to the following steps: by weight, add in the reaction kettle successively: 320 parts of water, 0.4 part of sodium acrylamido isopropyl sulfonate, 25 parts of acrylic acid, 15 parts of propylene Amide, 36 parts of butyl acrylate, and 4 parts of laurate were stirred and blended at 400 rpm. When the temperature rises to 82°C, add sodium persulfate to initiate polymerization, and ...

Embodiment 2

[0035] In the present embodiment, sodium persulfate is still used as the initiator, and the difference is that allyloxy hydroxypropyl sulfonate and veova10 (vinyl tertiary carbonate) are used as amphiphilic reactive emulsifiers and have improved macromolecular chain Flexible functional monomers with special functional groups, using a mixture of acrylic acid, acrylamide, butyl acrylate, ethyl acrylate and itaconic acid as acrylate monomers, wherein itaconic acid and part of acrylic acid start to initiate polymerization after a period of time Add together with some water, the ratio of acrylate monomer, amphiphilic reactive emulsifier and functional monomer in the whole preparation process is: 17:0.25:2.5.

[0036] Concretely prepare the solution of lithium-ion battery cathode water-based binder according to the following steps: by weight, add in the reaction kettle successively: 260 parts of water, 1 part of allyloxy sodium hydroxypropane sulfonate, 10 parts of acrylic acid, 12 p...

Embodiment 3

[0039] The manganese + ternary system was used as the positive electrode electroactive material, and the aqueous binder solution prepared in Example 2 was used to prepare the positive electrode slurry. The ratio of materials in the entire positive electrode slurry is: water-based binder, 2.0%; positive electrode material, 95%; conductive agent S-P, 3%.

[0040] The positive electrode slurry prepared above has a solid content of 70% and a viscosity of 8000 mPa.s. The slurry has good thixotropy. The coating process adopts an 18m drying tunnel, where the temperature of the drying tunnel is set at 90°C-110°C-120°C-100°C-90°C, and the coating speed is 8 m / min. The positive electrode sheet made of the slurry is smooth, free from crimping and cracking, has a high packing density, and has a high yield of the electrode sheet.

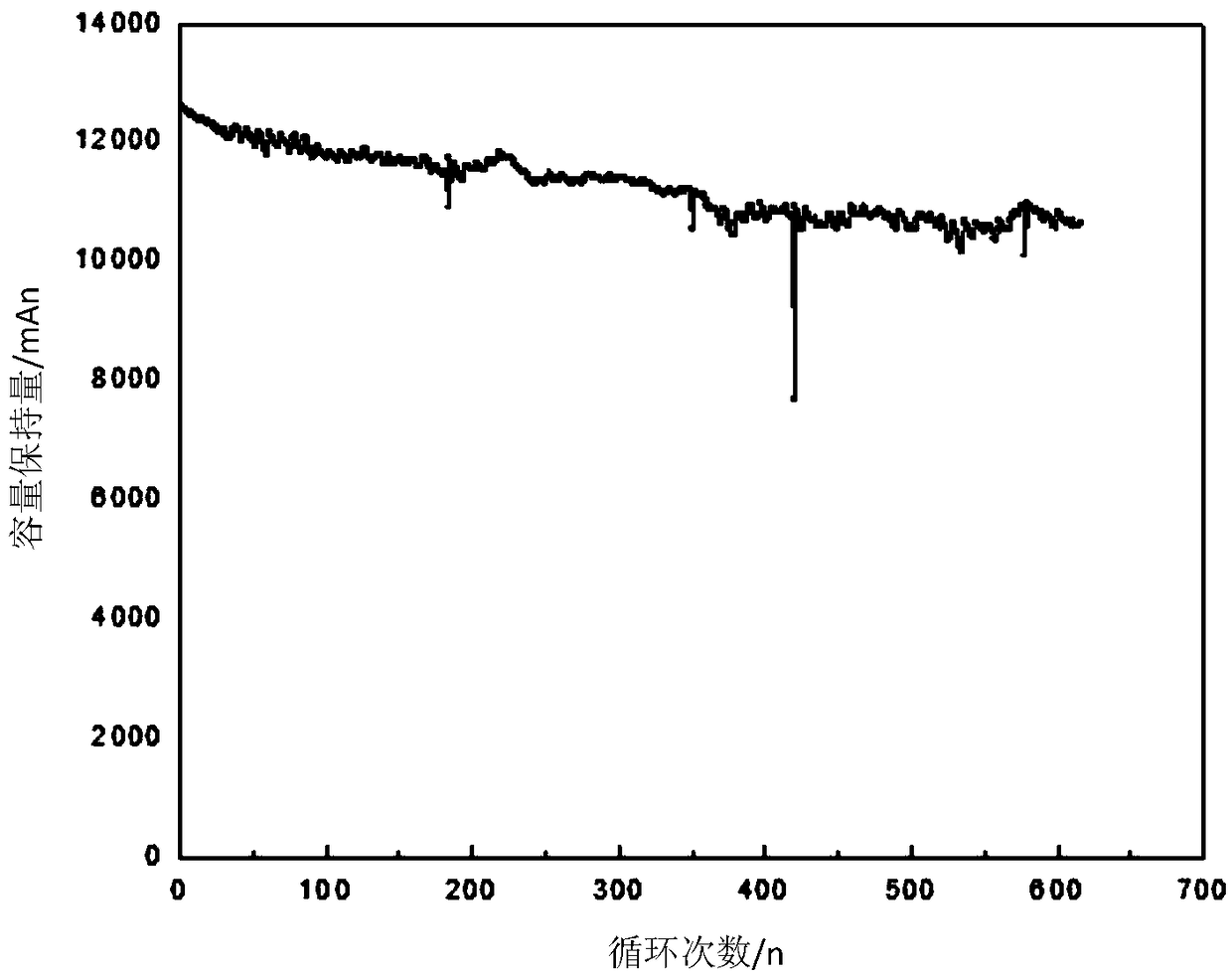

[0041] The above-mentioned positive pole piece is matched with lithium manganese oxide (BN-M01) active material to assemble a lithium-ion experimental battery,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

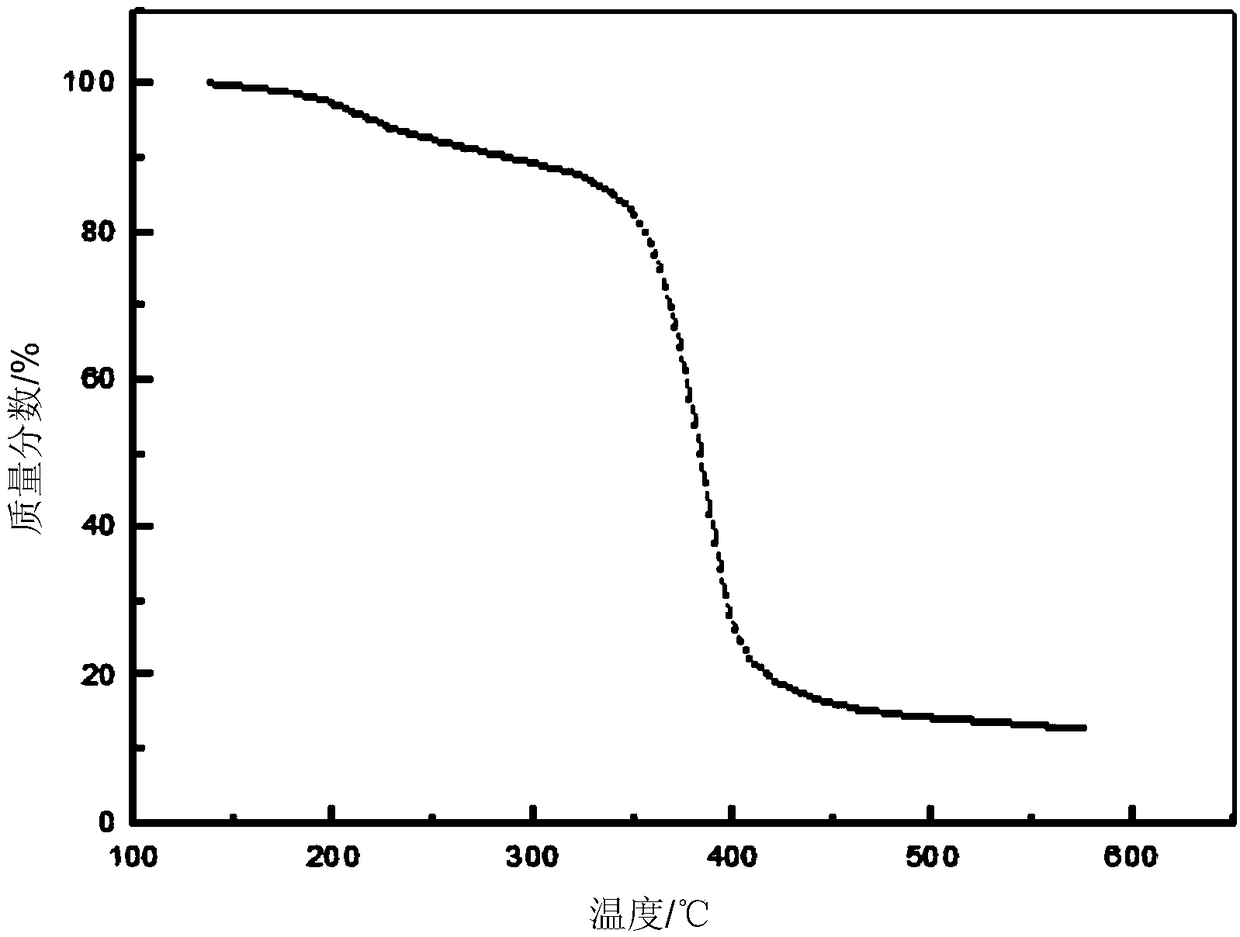

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com