Transparent and mildew-proof silane-modified polyether sealant and preparation method thereof

A mildew-resistant silane and sealant technology, which is applied in the field of transparent mildew-resistant silane-modified polyether sealant and its preparation, can solve the problems of poor environmental protection and poor durability of mildew resistance, and achieve improved mildew resistance and good weather resistance , the effect of not easy to organic volatiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

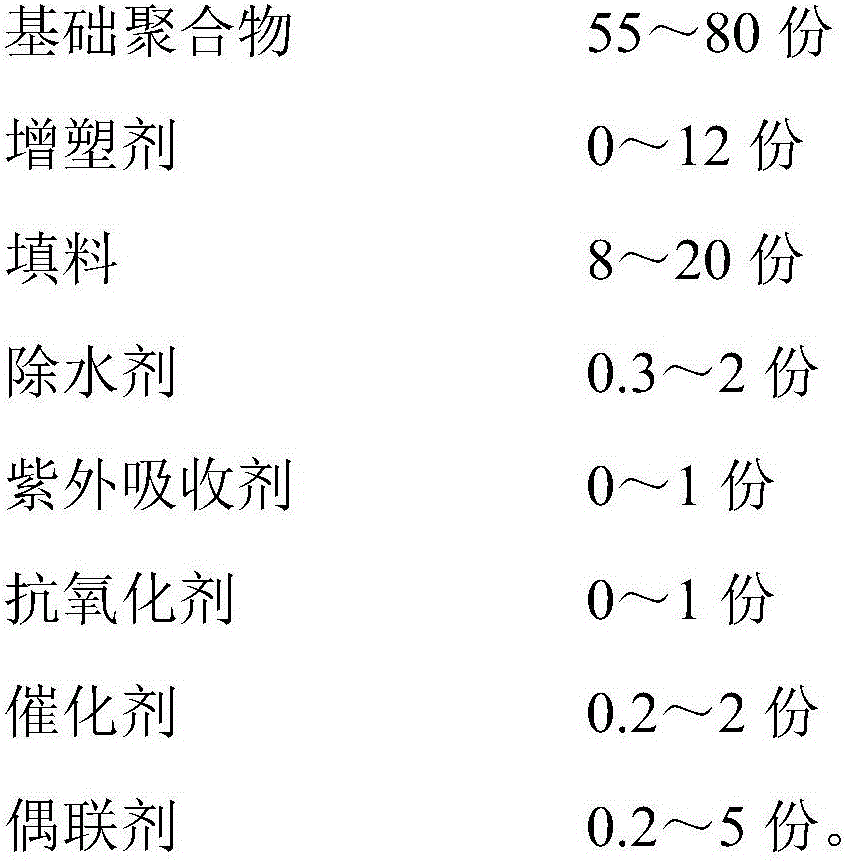

[0032] A transparent mildew-proof silane-modified polyether sealant, which consists of the following components in parts by weight:

[0033]

[0034]

[0035] The preparation of described transparent mildew-proof silane modified polyether sealant comprises the following steps:

[0036] A. Add the modified polyether of basic polymer terminal trimethoxysiloxane, plasticizer diisodecyl phthalate, ultraviolet absorber, and antioxidant into the high-speed disperser, mix at room temperature for 1 hour, and mix well;

[0037] B. Add filler R972 hydrophobic silica into the high-speed disperser, heat up to 110°C, stir and vacuum dehydrate at high speed for 3 hours under the vacuum degree of -0.0095MPa, until the moisture content is below 5 / 10,000;

[0038] C. Cool the reaction solution below 50°C, then add the catalyst dibutyltin dilaurate, water remover vinyltrimethoxysilane, coupling agent γ-aminopropyltriethoxysilane, control the stirring speed and pass the cooling Water, to ...

Embodiment 2

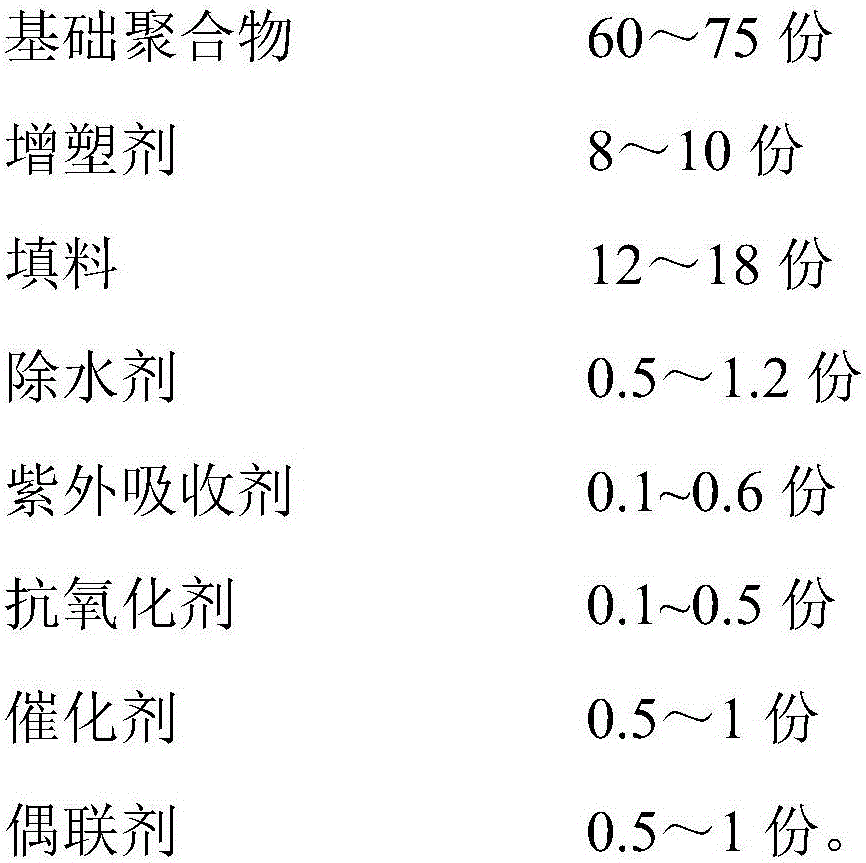

[0040] A transparent mildew-proof silane-modified polyether sealant, which consists of the following components in parts by weight:

[0041]

[0042]

[0043] The preparation of described transparent mildew-proof silane modified polyether sealant comprises the following steps:

[0044] A: Add the base polymer, plasticizer, UV absorber, and antioxidant into the high-speed disperser, mix at room temperature for 2 hours, and mix well;

[0045] B: Add fillers to the high-speed disperser, raise the temperature to 10°C, stir and vacuum dehydrate at high speed for 3 hours under the condition of vacuum degree -0.0095MPa, until the moisture content is below 5 / 10,000;

[0046] C: Cool the reaction solution below 50°C, then add catalyst, water remover, coupling agent, control the stirring speed and pass cooling water to ensure that the temperature of the rubber material is below 50°C; stir for 1 hour, vacuum degassing and filling, A transparent anti-mildew silane-modified polyethe...

Embodiment 3

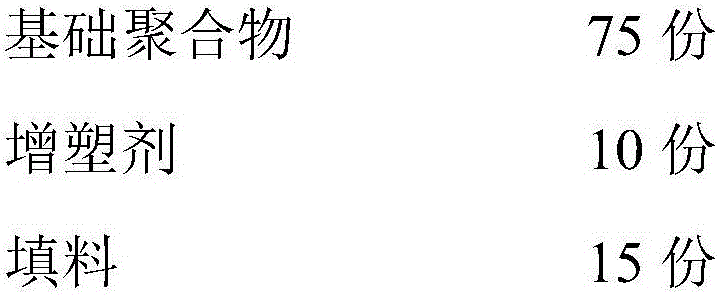

[0048] A transparent mildew-proof silane-modified polyether sealant, which consists of the following components in parts by weight:

[0049]

[0050] The preparation of described transparent mildew-proof silane modified polyether sealant comprises the following steps:

[0051] A: Add the base polymer, plasticizer, UV absorber, and antioxidant into the high-speed disperser, mix at room temperature for 1.5 hours, and mix well;

[0052] B: Add fillers to the high-speed disperser, raise the temperature to 105°C, stir and vacuum dehydrate at a high speed for 3 hours at a vacuum degree of -0.0095MPa, until the moisture content is below 5 / 10,000;

[0053] C: Cool the reaction solution below 50°C, then add catalyst, water remover, coupling agent, control the stirring speed and pass cooling water to ensure that the temperature of the rubber material is below 50°C; stir for 1 hour, vacuum degassing and filling, A transparent anti-mildew silane-modified polyether sealant was prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com