Method for fast separating polysaccharides from dragon fruit by counter-current chromatography

A technology of countercurrent chromatography and dragon fruit is applied in the fields of food processing and utilization and functional food manufacturing, which can solve the problems of slow speed, limited amount of separation and high cost, and achieve the expansion of application range, fast separation speed and large injection volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

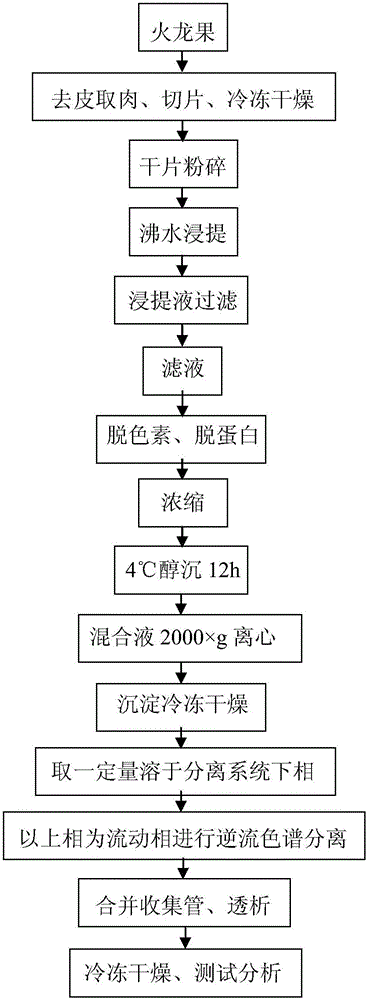

[0046] Embodiment 1, a kind of method (utilize counter-current chromatography to separate the method for polysaccharide rapidly from pitaya) of polysaccharide from pitaya, carry out following steps successively:

[0047] (1) Peel the dragon fruit and take the pulp, slice the pulp to a thickness of 3-5mm, and freeze-dry it at a temperature of -50-55°C and a vacuum of 50-100Pa until it is made into a product with a water content of ≤0.05%. Dried dragon fruit slices (drying time is about 24h).

[0048] Put 200g of dried dragon fruit slices into a blender and crush until passing through a 200-300 mesh sieve to obtain dried dragon fruit powder, add it to a large beaker filled with 8.0L distilled water, heat to boiling, keep at 100°C, cook and extract for 3 hours ;

[0049] Replace the dried pitaya slices with the residue obtained after the extraction and repeat the above-mentioned boiling water extraction for 2 times, and combine all the extracts.

[0050] (2) The combined extracts...

Embodiment 2

[0062] Embodiment 2, a kind of method for separating and preparing polysaccharide from pitaya, carries out following steps successively:

[0063] (1), the preparation method of dragon fruit dried slice is the same as embodiment 1.

[0064] Put 180g of dried dragon fruit slices into a blender and crush until passing through a 200-300 mesh sieve to obtain dried dragon fruit powder, add it to a large beaker filled with 7.0L distilled water, heat to boiling, keep at 100°C, cook and extract for 2.5 h;

[0065] Replace the dried pitaya slices with the residue obtained after the extraction and repeat the above-mentioned boiling water extraction for 2 times, and combine all the extracts.

[0066] (2) The combined extracts are cooled to room temperature and filtered, and the filtrate is concentrated, depigmented, deproteinized in turn, and concentrated again to obtain a concentrated solution;

[0067] details as follows:

[0068] Concentrate the filtrate (concentrate with a rotary e...

Embodiment 3

[0073] Embodiment 3, a kind of method for separating and preparing polysaccharide from pitaya, carries out following steps successively:

[0074] (1), the preparation method of dragon fruit dried slice is the same as embodiment 1.

[0075] Put 180g of dried dragon fruit slices into a grinder and grind until passing through a 200-300 mesh sieve to obtain dried dragon fruit powder, add it to a large beaker filled with 8.0L distilled water, heat to boiling, keep at 100°C, cook and extract for 3 hours ;

[0076] Replace the dried pitaya slices with the residue obtained after the extraction and repeat the above-mentioned boiling water extraction for 2 times, and combine all the extracts.

[0077] (2) The combined extracts are cooled to room temperature and filtered, and the filtrate is concentrated, depigmented, deproteinized in turn, and concentrated again to obtain a concentrated solution;

[0078] details as follows:

[0079] Concentrate the filtrate (concentrate with a rotar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com