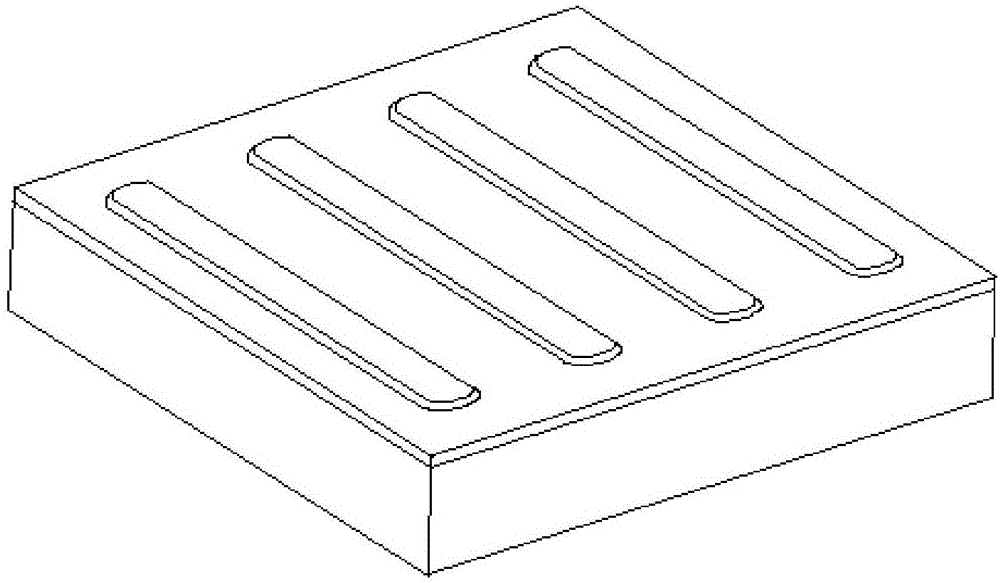

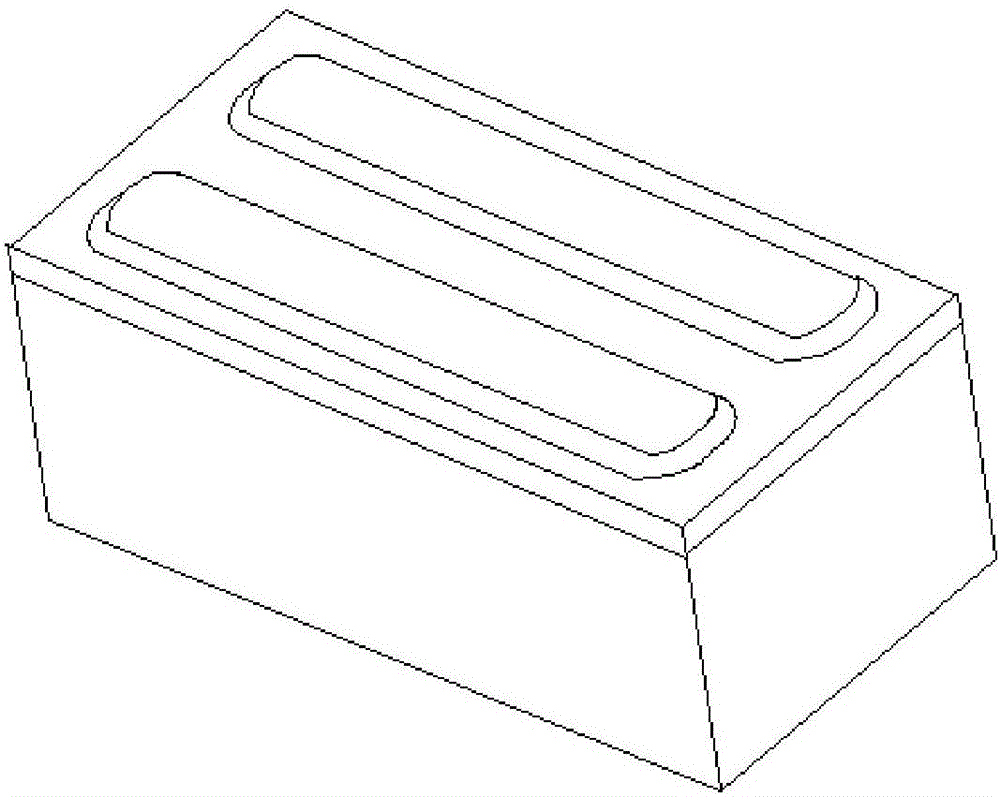

Cement polymer based high-temperature concrete permeable pavement bricks and manufacturing method thereof

A high-performance concrete and permeable pavement brick technology, applied in the field of pavement materials, can solve the problems of easy cracking of the permeable surface layer, poor water permeability, difficult to satisfy, etc., and achieves inhibition of alkali white pollution, high compressive strength, Improve the effect of transition zone structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0062] A cement polymer-based high-performance concrete permeable pavement brick, including a permeable base layer and a permeable surface layer. The parts by weight of the components in the raw material of the permeable base layer are: 290 parts of cement A, 0.5 parts of ultra-light aggregate, 1765 parts of coarse aggregate, 255 parts of sand, 0.50 parts of polymer emulsion A, 0.50 parts of interface enhancer, 0 parts of bulk mud shrinkage inhibitor, 97.5 parts of deionized water;

[0063]The cement described in the permeable base of this embodiment is Portland cement with a strength grade of 42.5; the ultra-light aggregate is polyphenylene particles; the coarse aggregate is quartzite gravel; the sand is mud-containing The amount is 3% (in parts by mass) of Jiangsha; the polymer emulsion is polyacrylate emulsion (PAE); agent and 84.5 parts of dispersant; the coupling agent is isopropyl trititanate, the curing agent is potassium silicate, and the dispersant is sodium polymethy...

specific Embodiment approach 2

[0089] A cement polymer-based high-performance concrete permeable pavement brick, including a permeable base layer and a permeable surface layer. The parts by weight of the components in the raw materials of the permeable base layer are: 300 parts of cement A, 1.5 parts of ultra-light aggregate, 1745 parts of coarse aggregate, 260 parts of sand, 0.55 parts of polymer emulsion A, 0.475 parts of interface enhancer, 0.15 parts of bulk shrinkage inhibitor, and 100 parts of deionized water;

[0090] The cement described in the permeable base of this embodiment is ordinary Portland cement with a strength grade of 42.5; the ultra-light aggregate is 1 part of polystyrene particles and 0.5 part of waste rubber particles; the coarse aggregate is crushed andesite stone; the sand is river sand with a mud content of 5% (by mass); the polymer emulsion is ethylene-vinyl acetate copolymer emulsion (EVA); the interface enhancer is 10 parts by weight The coupling agent, the curing agent of 7.5 ...

specific Embodiment approach 3

[0099] A cement polymer-based high-performance concrete permeable pavement brick, including a permeable base layer and a permeable surface layer. The parts by weight of the components in the raw material of the permeable base layer are: cement A310 parts, ultra-light aggregate A2 parts, coarse bone 1730 parts of material, 265 parts of sand, 0.60 parts of polymer emulsion A, 0.45 parts of interface enhancer, 0.35 parts of bulk mud shrinkage inhibitor, and 97 parts of deionized water;

[0100]The cement described in the permeable base of this embodiment is Portland cement with a strength grade of 52.5; the ultra-light aggregate is 1.5 parts of polystyrene particles and 0.5 parts of waste rubber particles; the coarse aggregate is diabase Gravel; Described sand is the mountain sand that mud content is 10% (by mass); Described polymer emulsion is polyvinyl acetate emulsion (PVAC); Described interfacial enhancer is by weight 12.5 Parts of coupling agent, 5.5 parts of curing agent an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Splitting tensile strength | aaaaa | aaaaa |

| Grinding pit length | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com