A production process of black chrome coating for high-performance heat collectors by continuous electroplating on metal strips

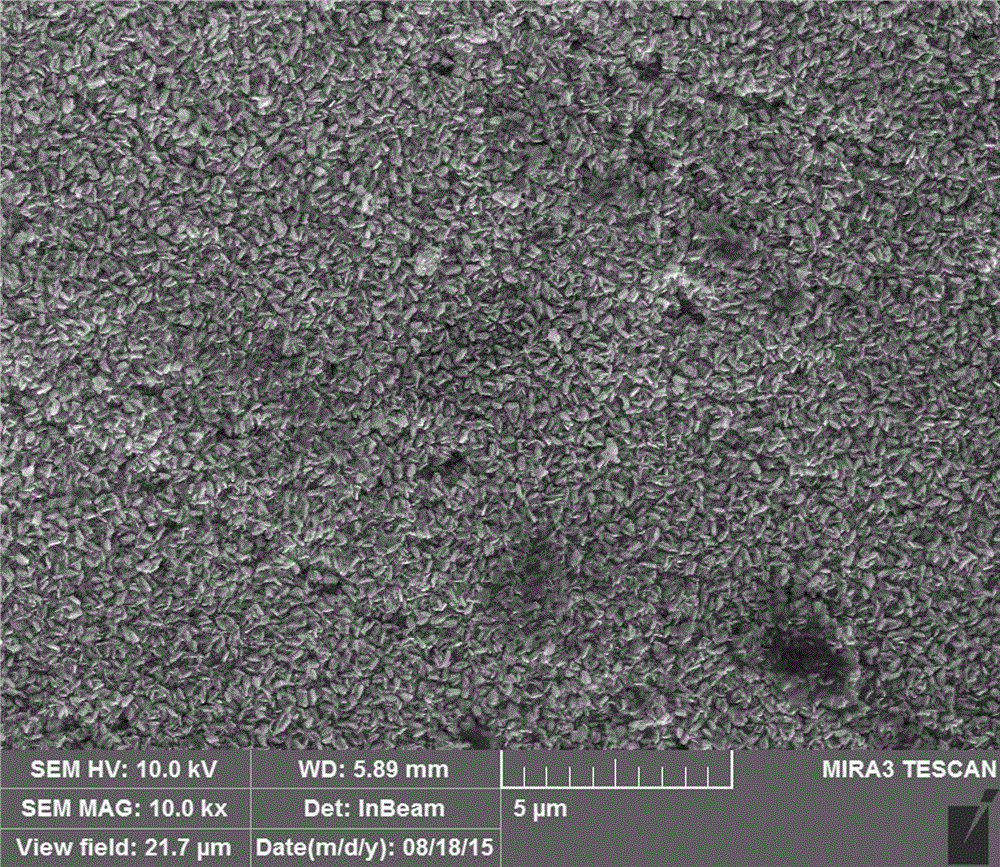

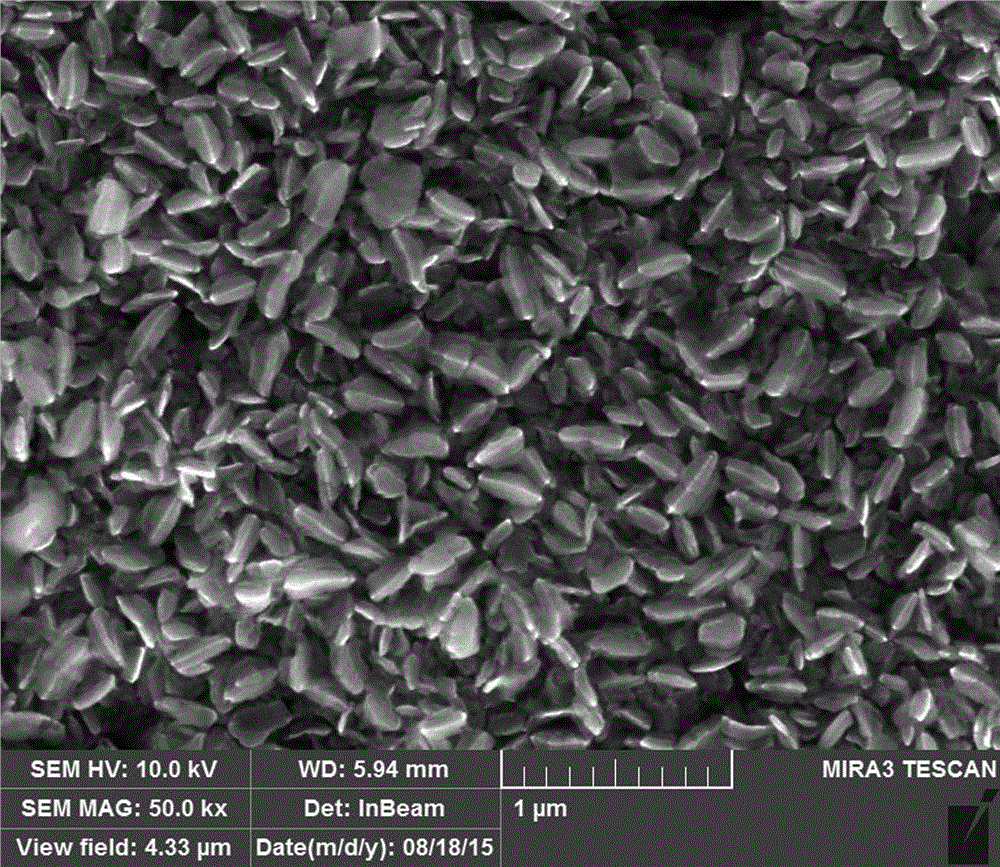

A technology of black chromium coating and production process, which is applied in the field of electroplating production process, can solve the problems of high current density, high production cost, poor conductivity of solution, etc., and achieve the effects of improved corrosion resistance, enhanced absorption, and uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

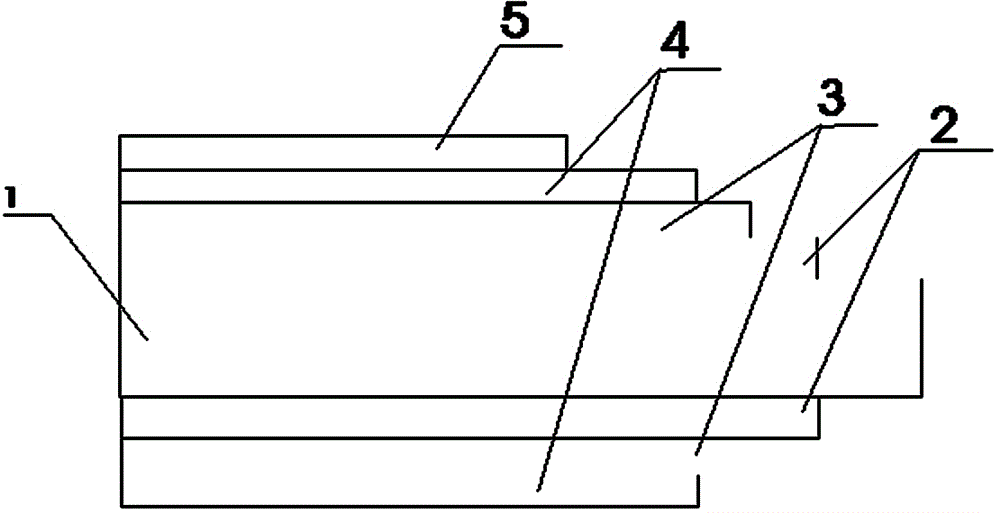

[0023] Embodiment 1: a kind of metal strip continuous electroplating high-performance heat collector black chrome coating production process, namely take metal plate and strip as base material, select aluminum plate strip as base material in the present embodiment, on it Continuous plating of black chrome coating, the specific process includes the following process procedures, followed by substrate pretreatment, quaternary alloy immersion zinc process, copper plating, nickel plating, chrome plating several process procedures;

[0024]The first is the material pretreatment process, the purpose of which is to remove impurities on the surface of the aluminum plate. The material pretreatment consists of four steps: alumina acid removal, water washing, alkali roughening agent, and water washing. The concentration of the aqueous solution is 12%, the operating temperature is 20°C, and the treatment time is 20°C. The degreasing agent can use the common electroplating degreasing agent i...

Embodiment 2

[0031] Embodiment 2: Embodiment 1: a kind of continuous electroplating high-performance heat collector black chromium coating production process for metal strips, promptly takes metal sheets and strips as the base material, and selects the copper plate strip as the base material in the present embodiment , on which the black chrome coating is continuously plated. The specific process includes the following process procedures, which are followed by substrate pretreatment, quaternary alloy zinc-immersion process, copper plating, nickel plating, and chrome plating;

[0032] The first is the material pretreatment process, the purpose of which is to remove impurities on the surface of the aluminum plate. The material pretreatment consists of four steps: alumina acid removal, water washing, alkali roughening agent, and water washing. Alumina acid removal uses a degreasing agent. Aluminum acid degreasing solution treatment, the concentration of the aqueous solution is 31%, the operati...

Embodiment 3

[0037] Embodiment 3: Embodiment 1: a kind of continuous electroplating high-performance heat collector black chromium coating production process for metal strips, that is, taking metal sheets and strips as base materials, selects stainless steel strips as base materials in the present embodiment The black chrome coating is continuously plated on it. The specific process includes the following process procedures, which are followed by substrate pretreatment, quaternary alloy immersion zinc process, copper plating, nickel plating, and chrome plating;

[0038] The first is the material pretreatment process, the purpose of which is to remove impurities on the surface of the aluminum plate. The material pretreatment consists of four steps: alumina acid removal, water washing, alkali roughening agent, and water washing. , the concentration of the aqueous solution is 19%, the operating temperature is 26°C, and the treatment time is 40s. The degreasing agent can use the common electrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com