Novel ultralight high-strength and high-plasticity magnesium lithium alloy and preparation method thereof

A magnesium-lithium alloy and ultra-light technology, which is applied in the field of new ultra-light, high-strength and high-plastic magnesium-lithium alloy and its preparation, can solve the problem that magnesium alloy cannot have high-strength, high-plasticity and room temperature molding at the same time, and achieves the advantage of reducing subsequent processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Ⅰ), alloy composition

[0023] Configure 10 kilograms of lithium-containing magnesium alloy materials according to the following proportions, and the weights of the alloy elements taken out are respectively: 1.2 kilograms of lithium (Li), 0.2 kilograms of zinc (Zn), 0.4 kilograms of yttrium (Y) and the rest of magnesium (Mg). In terms of weight percentage, the alloy composition is Mg-12%Li-2%Zn-4%Y.

[0024] Ⅱ), alloy smelting

[0025] Alloy smelting is divided into two steps:

[0026] 1) In a crucible with a capacity of 10 kg and a resistance furnace, fully stir, alloy elements Y and Zn are melted, and a Mg-2%-4%Y alloy is prepared.

[0027] 2) Put Mg-2%-4%Y alloy and pure lithium in a vacuum furnace for remelting. When the alloy is completely melted, it is kept at 720°C for 30 minutes and poured in a vacuum furnace.

[0028] Ⅲ), homogenization and deformation processing

[0029] 1) Peel the ingot.

[0030] 2) Wrap the peeled ingot tightly with aluminum foil, an...

Embodiment 2

[0037] Ⅰ), alloy composition

[0038] According to the following proportions, 10 kilograms of lithium-containing magnesium alloy materials are weighed to take out elements: 1.4 kilograms of lithium (Li), 0.3 kilograms of zinc (Zn), 0.6 kilograms of yttrium (Y) and the rest of magnesium (Mg). In terms of weight percentage, the alloy composition is Mg-14%Li-3%Zn-6%Y.

[0039] Ⅱ), alloy smelting

[0040] The smelting of reference example 1. The difference is that the zinc (Zn) and yttrium (Y) contents of the two are different.

[0041] Ⅲ), homogenization and deformation processing

[0042] Refer to the homogenization and rolling procedure of Example 1.

[0043] Ⅳ), microstructure characterization

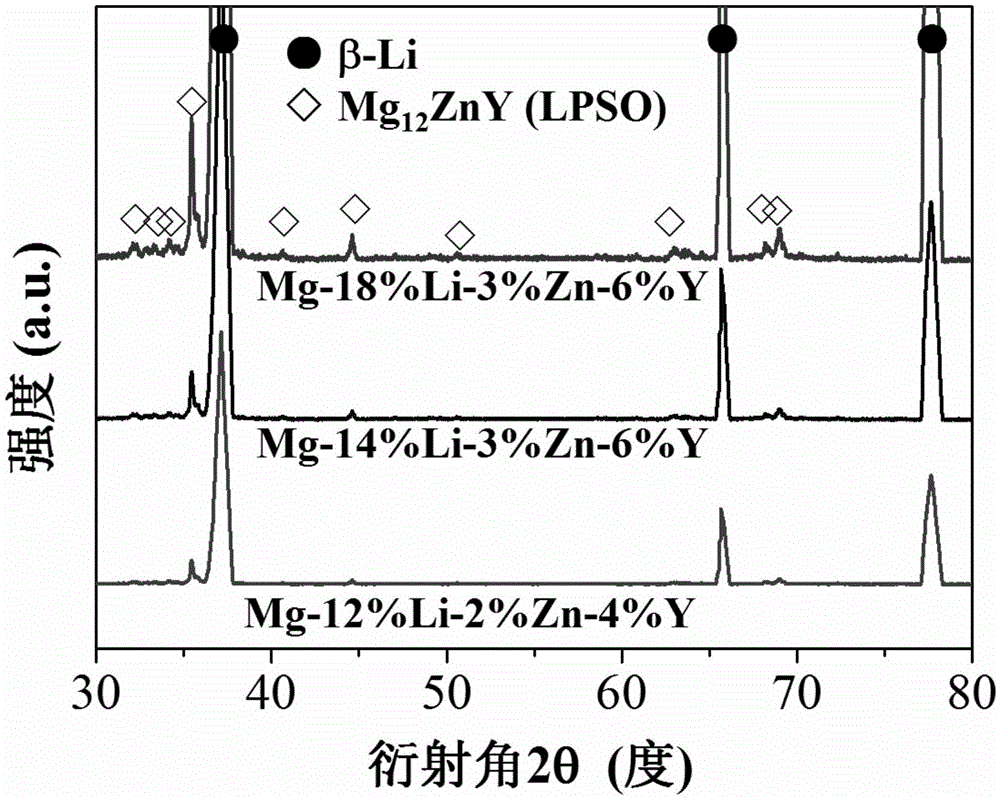

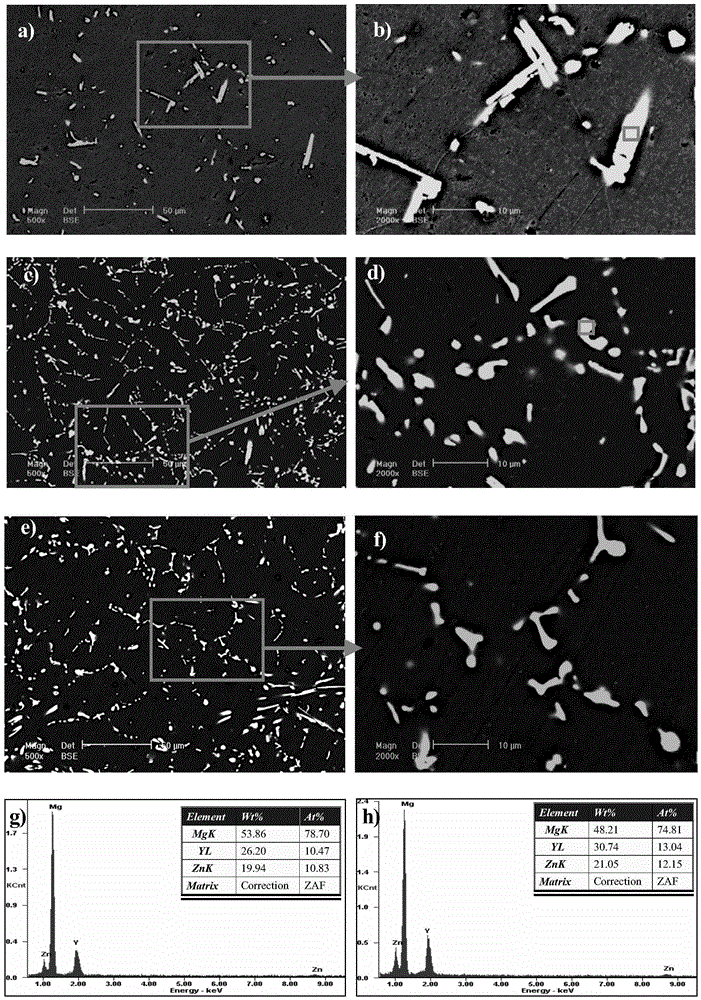

[0044] Refer to the microstructure characterization of Example 1. The main phases in the alloy are β-Li and Mg 12 ZnY (LPSO phase), the corresponding X-ray spectrum is shown in the attached figure 1 ; Compared with the alloy in Example 1, the amount of the LPSO phase in this al...

Embodiment 3

[0048] Ⅰ), alloy composition

[0049] According to the following proportions, 10 kilograms of lithium-containing magnesium alloy materials are weighed to take out elements: 1.8 kilograms of lithium (Li), 0.3 kilograms of zinc (Zn), 0.6 kilograms of yttrium (Y) and the rest of magnesium (Mg). In terms of weight percentage, the alloy composition is Mg-18%Li-3%Zn-6%Y.

[0050] Ⅱ), alloy smelting

[0051] The smelting of reference example 1. The difference is that the zinc (Zn) and yttrium (Y) contents of the two are different.

[0052] Ⅲ), homogenization and deformation processing

[0053] Refer to the homogenization and rolling procedure of Example 1.

[0054] Ⅳ), microstructure characterization

[0055] Refer to the microstructure characterization of Example 1. The main phases in the alloy are β-Li and Mg 12 ZnY (LPSO phase), the corresponding X-ray spectrum is shown in the attached figure 1 Compared with the alloy in Example 2, the amount of the LPSO phase in the alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com