A kind of polyvinyl chloride flame retardant board and its production process

A technology of polyvinyl chloride and flame retardant board is applied in the field of production technology of polyvinyl chloride flame retardant board, which can solve the problems of low impact strength, poor processing performance, limited types, etc., and achieves good impact resistance performance and low processing temperature. , The effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

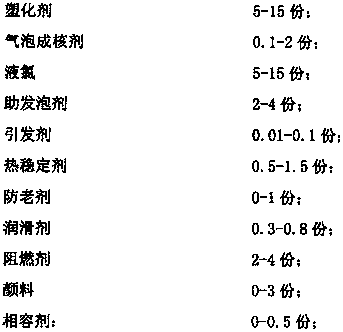

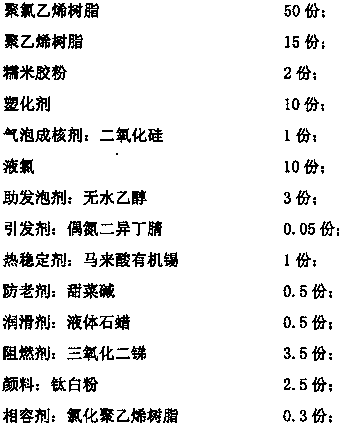

[0042] A polyvinyl chloride flame retardant board, comprising the following raw material components by weight:

[0043]

[0044]

[0045] The chlorine content of the chlorinated polyethylene resin is 35%; the plasticizer is compounded from dichloromethane, absolute ethanol and acetone in a weight ratio of 4.5:4.5:1.

[0046] Its production process is:

[0047] Step 1: Weigh each raw material according to the above weight for later use, first add polyvinyl chloride resin, polyethylene resin, glutinous rice glue powder, plasticizer, bubble nucleating agent, initiator, heat stabilizer, anti-aging agent into the mixing kettle , lubricant, flame retardant, pigment and compatibilizer, mix at 115°C at 1400r / min for 15min to mature the material; then cool down to 30°C, add plasticizer, and continue to mix at 1400r / min for 15min to make a prefabricated mix;

[0048] Step 2: Add the premix into the hopper of the twin-screw foaming extruder, set the barrel temperature of the twin...

Embodiment 2

[0051] A polyvinyl chloride flame retardant board, comprising the following raw material components by weight:

[0052]

[0053] The chlorine content of the chlorinated polyethylene resin is 35%; the plasticizer is compounded from dichloromethane, absolute ethanol and acetone in a weight ratio of 4.5:4.5:1.

[0054] Its production process is:

[0055] Step 1: Weigh each raw material according to the above weight for later use, first add polyvinyl chloride resin, polyethylene resin, glutinous rice glue powder, plasticizer, bubble nucleating agent, initiator, heat stabilizer, anti-aging agent into the mixing kettle , lubricant, flame retardant, pigment and compatibilizer, mix at 115°C at 1400r / min for 15min to mature the material; then cool down to 30°C, add plasticizer and continue to mix at 1400r / min for 15min to make a pre- mix;

[0056] Step 2: Add the premix into the hopper of the twin-screw foaming extruder, set the barrel temperature of the twin-screw foaming extrude...

Embodiment 3

[0059] A polyvinyl chloride flame retardant board, comprising the following raw material components by weight:

[0060]

[0061] The plasticizer is compounded from dichloromethane, absolute ethanol and acetone in a weight ratio of 4.5:4.5:1.

[0062] Its production process is:

[0063] Step 1: Weigh each raw material by weight for later use, first add polyvinyl chloride resin, polyethylene resin, glutinous rice glue powder, plasticizer, bubble nucleating agent, initiator, heat stabilizer, anti-aging agent, After lubricant, flame retardant and pigment, mix at 117°C at 1400r / min for 15min to mature the material; then cool down to 40°C, add plasticizer and continue mixing at 1400r / min for 15min to make a premix;

[0064] Step 2: Add the premix into the hopper of the twin-screw foaming extruder, set the barrel temperature of the twin-screw foaming extruder to 110-120°C, and the pressure inside the twin-screw foaming extruder to be 10MPa~ 15MPa, after the mixture is fully mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com