Bone repair material and its preparation method and application

A bone repair and structure-directing agent technology, applied in the field of bioengineering, can solve the problems of epidermal growth factor metabolism speed cannot complete the bone repair process, poor adsorption and release ability of biological macromolecules, poor differentiation ability in the direction of osteogenesis, etc., to achieve long-term effect Rapid bone repair process, enhance repair effect and speed, promote proliferation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

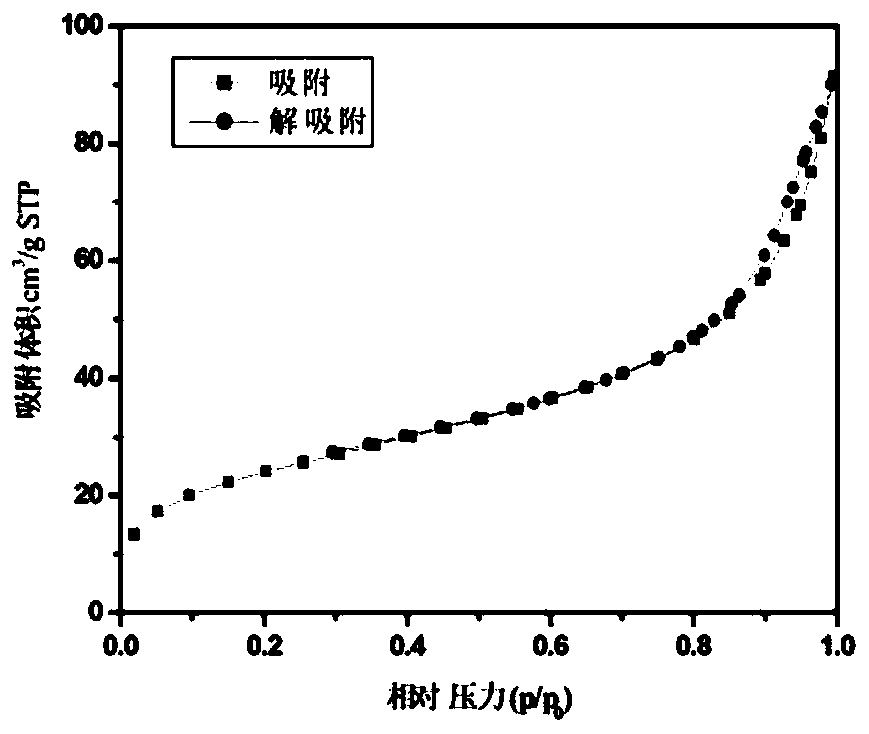

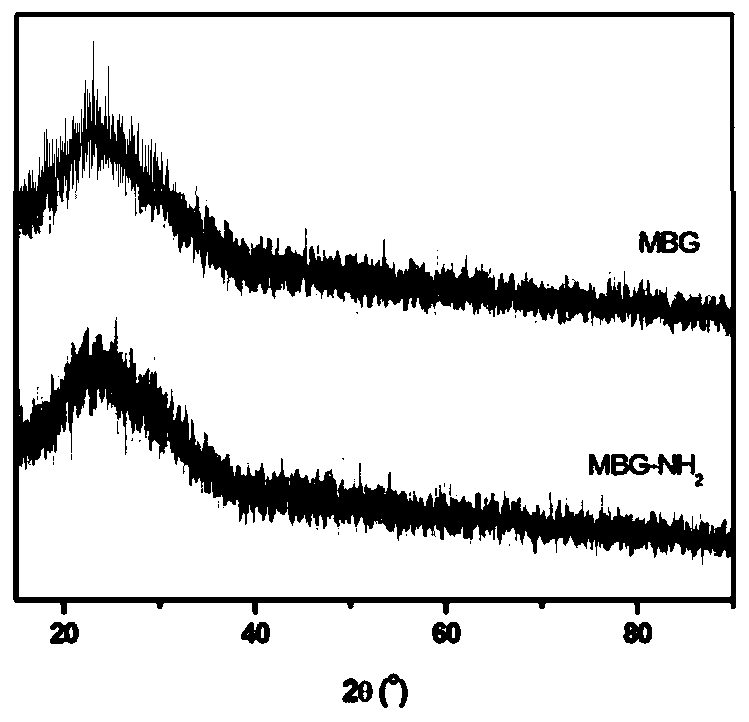

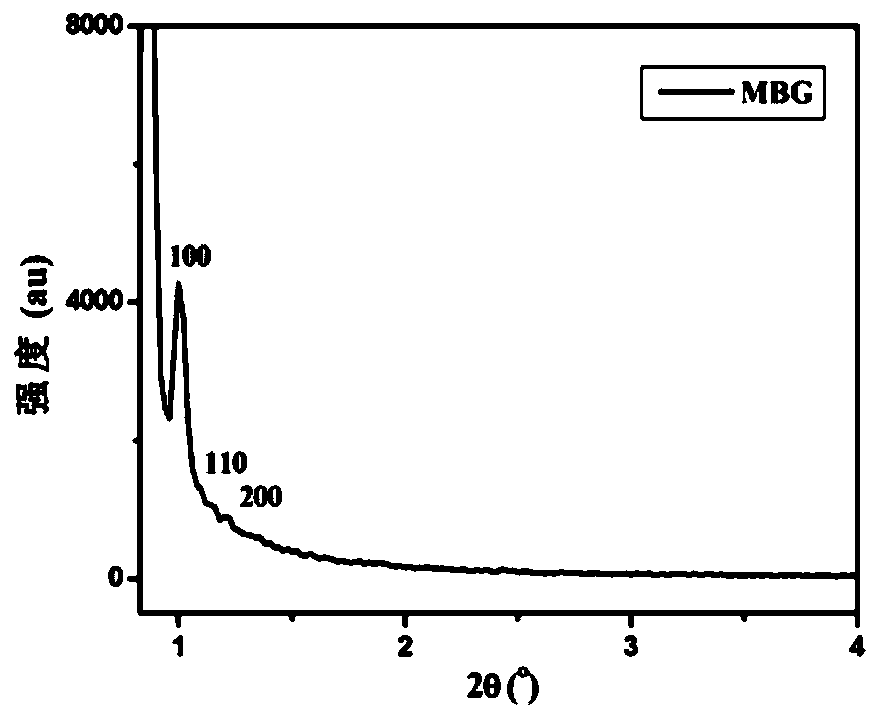

[0050] Bioactive glass (MBG) was synthesized by a combined approach of template induction and self-assembly. 4.5g structure directing agent nonionic block copolymer PEO 20 -PPO 70 -PEO 20 (P123) was dissolved in 240 ml of water, the pH value of the solution was adjusted to 1 with HCl, 6.5 g of pore-enlarging agent 1,3,5-mesitylene (TMB) was added, stirred for 3 hours until uniform, and then 7 ml of orthosilicic acid was added Ethyl ester (TEOS), 3.65g Ca(NO 3 ) 2 4H 2 O calcium source, 2.5g triethyl phosphate (TEP), after stirring at 40°C for 24 hours, adjust the pH to 10 with concentrated ammonia water, and let it stand at 110°C for 50 hours to obtain a precipitate. The obtained precipitate was washed several times with deionized water until the pH was 7, and fired at 550° C. for 10 hours to obtain a bioactive glass material. The bioactive glass material was mixed with 3-aminopropyltriethoxysilane (APTES, the molecular formula is C 9 h 23 NO 3 Si,), mixed for 20 hour...

Embodiment 2

[0063] Bioactive glass (MBG) was synthesized by a combined approach of template induction and self-assembly. 6 g of structure directing agent nonionic block copolymer PEO 20 -PPO 70 -PEO 20 (P123) was dissolved in 240 ml of water, the pH value of the solution was adjusted to 1 with HCl, 10 g of pore-enlarging agent 1,3,5-mesitylene (TMB) was added, stirred at 40°C for 6 hours until uniform, and then 10 ml of Orthoethyl silicate (TEOS), 4.55g Ca(NO 3 ) 2 4H 2 O, 2.5g of triethyl phosphate (TEP), stirred at 45°C for 24 hours, adjusted the pH to 11 with concentrated ammonia water, and allowed to stand at 90°C for 56 hours to obtain a precipitate. The obtained precipitate was washed several times with deionized water until the pH was 7.4, and fired at 550° C. for 10 hours to obtain a bioactive glass material. The bioactive glass material was mixed with 3-aminopropyltriethoxysilane (APTES, the molecular formula is C 9 h 23 NO 3 Si,), mixed for 14 hours, baked at 150°C for ...

Embodiment 3

[0065] Bioactive glass (MBG) was synthesized by a combined approach of template induction and self-assembly. 4 g of structure directing agent nonionic block copolymer PEO 20 -PPO 70 -PEO 20 (P123) was dissolved in 240 ml of water, the pH of the solution was adjusted to 2 with HCl, 6 g of pore-enlarging agent 1,3,5-mesitylene (TMB) was added, stirred for 3 hours until uniform, and then 6 ml of ethyl orthosilicate was added Ester (TEOS), 2.75g calcium chloride, 2.5g triethyl phosphate (TEP), stirred at 50°C for 20 hours, adjusted the pH to 9 with concentrated ammonia water, and allowed to stand at 110°C for 80 hours to obtain a precipitate. The obtained precipitate was washed several times with deionized water until the pH was 7, and fired at 600° C. for 6 hours to obtain a bioactive glass material. The bioactive glass material was mixed with 3-aminopropyltriethoxysilane (APTES, the molecular formula is C 9 h 23 NO 3 Si,), mixed for 20 hours, baked at 80°C for 30 hours, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com