Preparation method of cuco2s4 nanoparticles

A technology of nanoparticles and copper salts, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high heat treatment temperature, increased synthesis steps, etc., and achieve good supercapacitive performance, low cost, and cheap raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ①In a 100mL flask, add 0.2 mmol of copper acetate, 0.4 mmol of cobalt acetate, and 9.6 mmol of oleylamine into 20 mL of anisole, stir and heat to 60°C for 30 minutes until completely dissolved.

[0019] ②Put the reaction solution prepared in step ① into a 30mL polytetrafluoroethylene liner autoclave containing 0.8 mmol thioacetamide. After solvothermal heating at 180°C for 24 hours, the reaction kettle is naturally cooled to 60°C. After centrifugation, Wash several times with methanol and absolute ethanol, and dry the sample in vacuum to obtain CuCo 2 S 4 Nanoparticles.

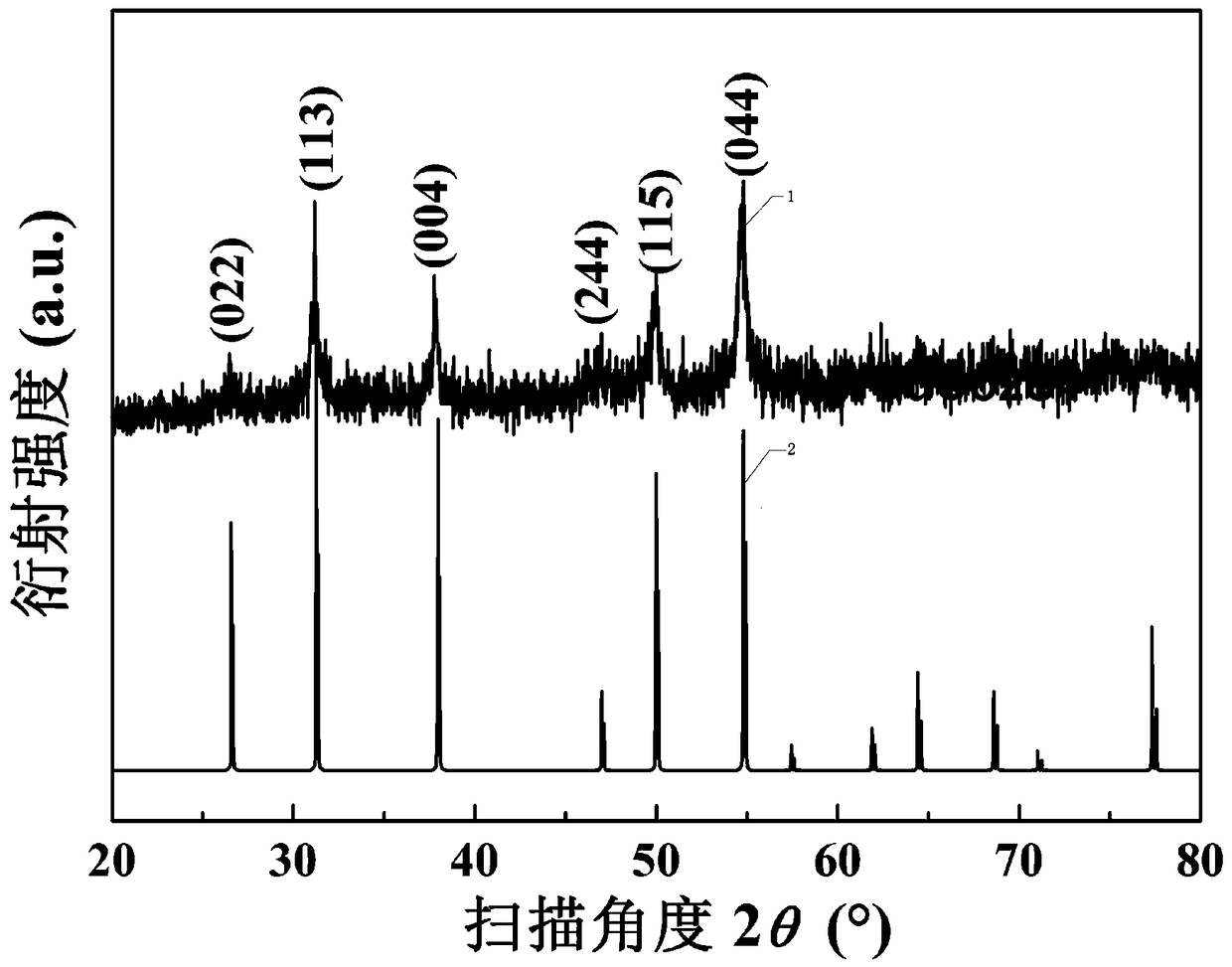

[0020] The resulting CuCo 2 S 4 The X-ray diffraction pattern of nanoparticles is attached figure 1 shown. Depend on figure 1 It can be seen that all the diffraction peaks are completely consistent with the standard cubic CuCo 2 S 4 Structure (JPCDS NO. 42-1450), genus Fd-3m space group, whose unit cell parameters are a = 0.9474 nm, no other impurities such as CoCu were detected 2 S 4 , C...

Embodiment 2

[0022] ①In a 100mL flask, add 0.4 mmol of copper acetate, 0.8 mmol of cobalt acetate, and 16 mmol of octadecylamine into 20 mL of anisole, stir and heat to 60°C, keep for 30 minutes until completely dissolved .

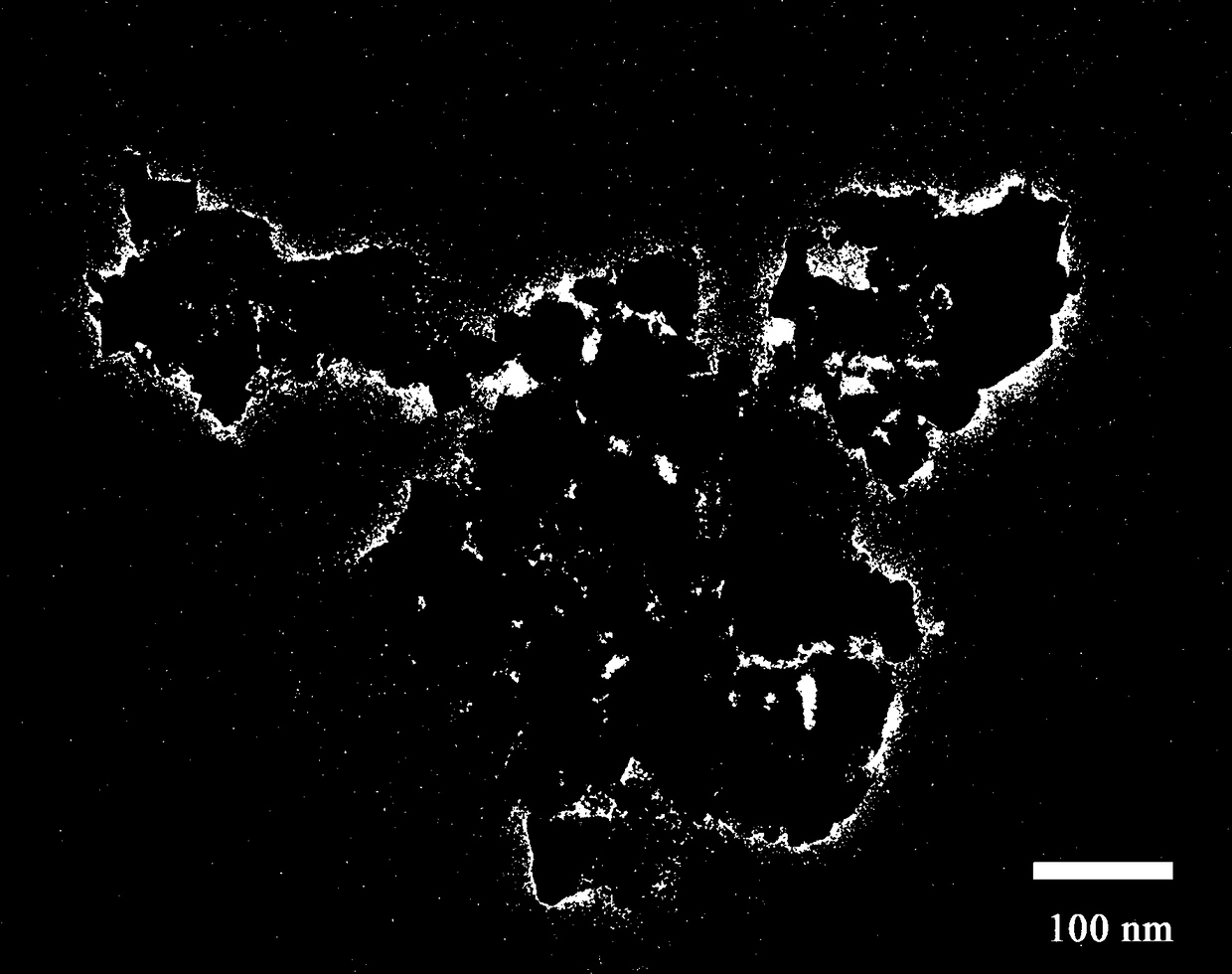

[0023] ②Transfer the reaction solution prepared in step ① into a 30mL polytetrafluoroethylene liner high-pressure reactor containing 1.6 mmol thioacetamide. , washed several times with absolute ethanol, and vacuum-dried the sample to obtain the same spherical CuCo 2 S 4 Nanoparticles, with an average size of 20-60 nanometers.

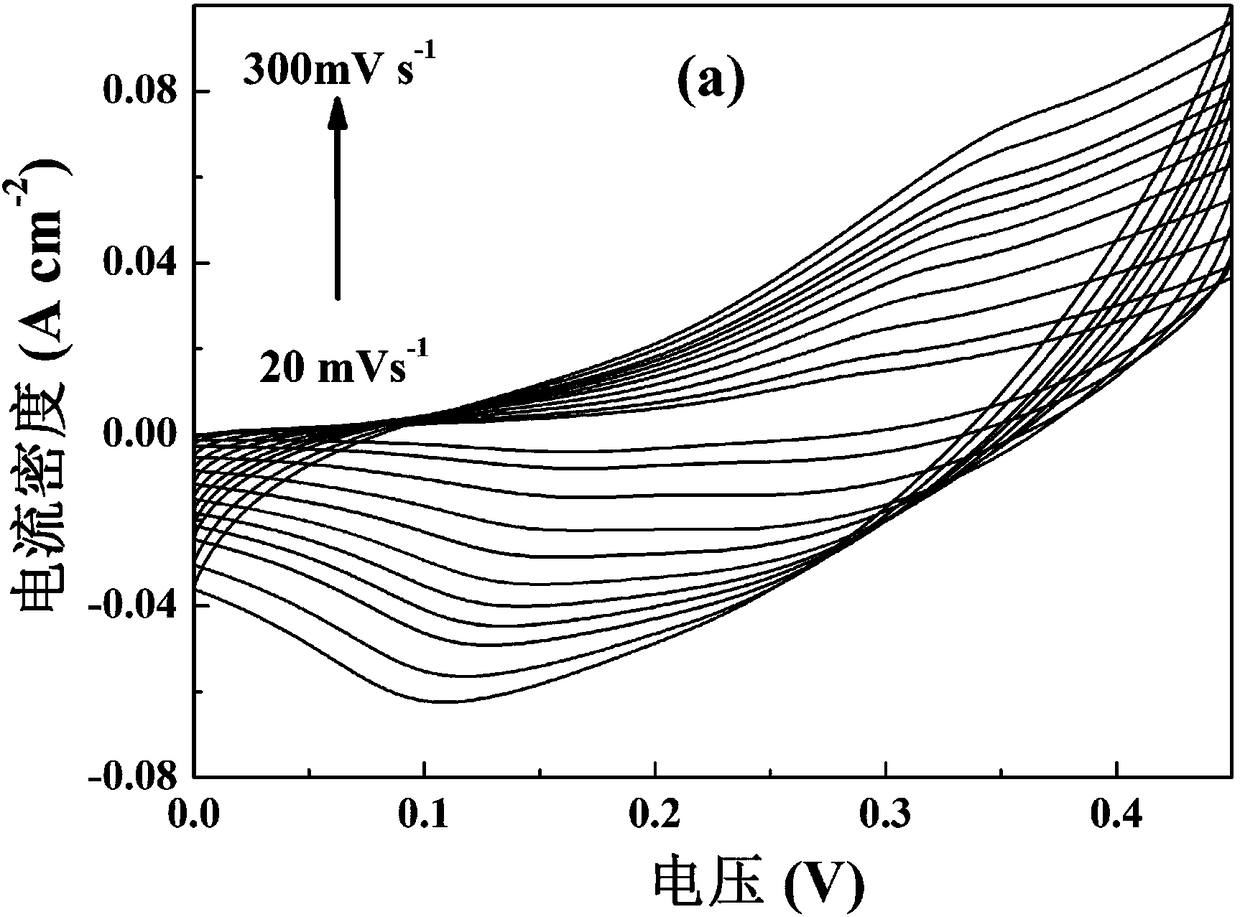

[0024] The obtained CuCo 2 S 4 Nanoparticles were made into supercapacitor working electrodes and their electrochemical properties were tested. Figure 3a is based on CuCo 2 S 4 Cyclic voltammograms of nanoparticle supercapacitor electrodes at different scan rates. It can be seen from the figure that the electrode exhibits a pair of obvious redox peaks, which indicates that CuCo 2 S 4 Nanoparticles are a typical pseudocapacitive materia...

Embodiment 3

[0026] ①In a 100mL flask, add 0.3 mmol of copper acetate, 0.6 mmol of cobalt acetate, and 13 mmol of oleylamine into 20 mL of anisole, stir and heat to 60°C, and keep for 30 minutes until completely dissolved.

[0027] ②Put the reaction solution prepared in step ① into a 30mL polytetrafluoroethylene liner autoclave containing 1.2 mmol thioacetamide. After 200°C solvent heating for 20 hours, the reaction kettle is naturally cooled to 60°C. After centrifugation, , washed several times with absolute ethanol, and vacuum-dried to obtain the same spherical CuCo as in Example 1. 2 S 4 Nanoparticles, with an average size of 20-60 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com