Method for preparing Nano nickelous diselenide in hexagon

A nickel diselenide and hexagonal technology, which is applied in nanostructure manufacturing, binary selenium/tellurium compounds, nanotechnology, etc., can solve the problems of unfavorable product shape control and large size, and achieve controllable shape and operation Simple, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ①In a 100ml beaker, add 0.4mmol of nickel acetylacetonate and 1ml of oleic acid to 39ml of anisole, stir magnetically for 30 minutes and then add 0.8mmol of selenium powder to prepare the reaction of nickel diselenide liquid.

[0019] ② Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 50ml polytetrafluoroethylene liner. After solvent heating at 180°C for 24 hours, the reactor was naturally cooled to room temperature, centrifuged, and washed with absolute ethanol for several Once, the sample was vacuum-dried to obtain nickel diselenide nanostars with a hexagonal shape.

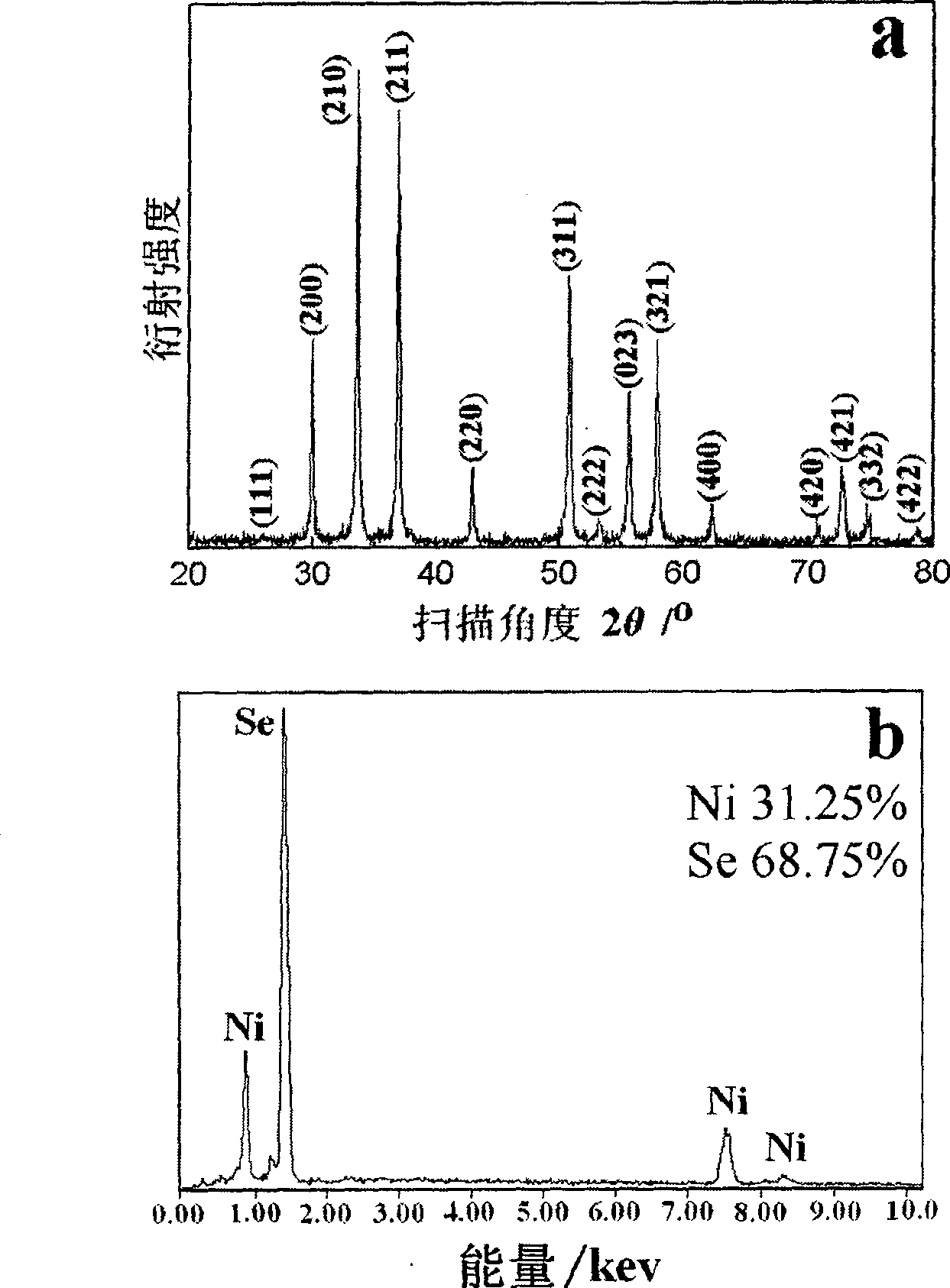

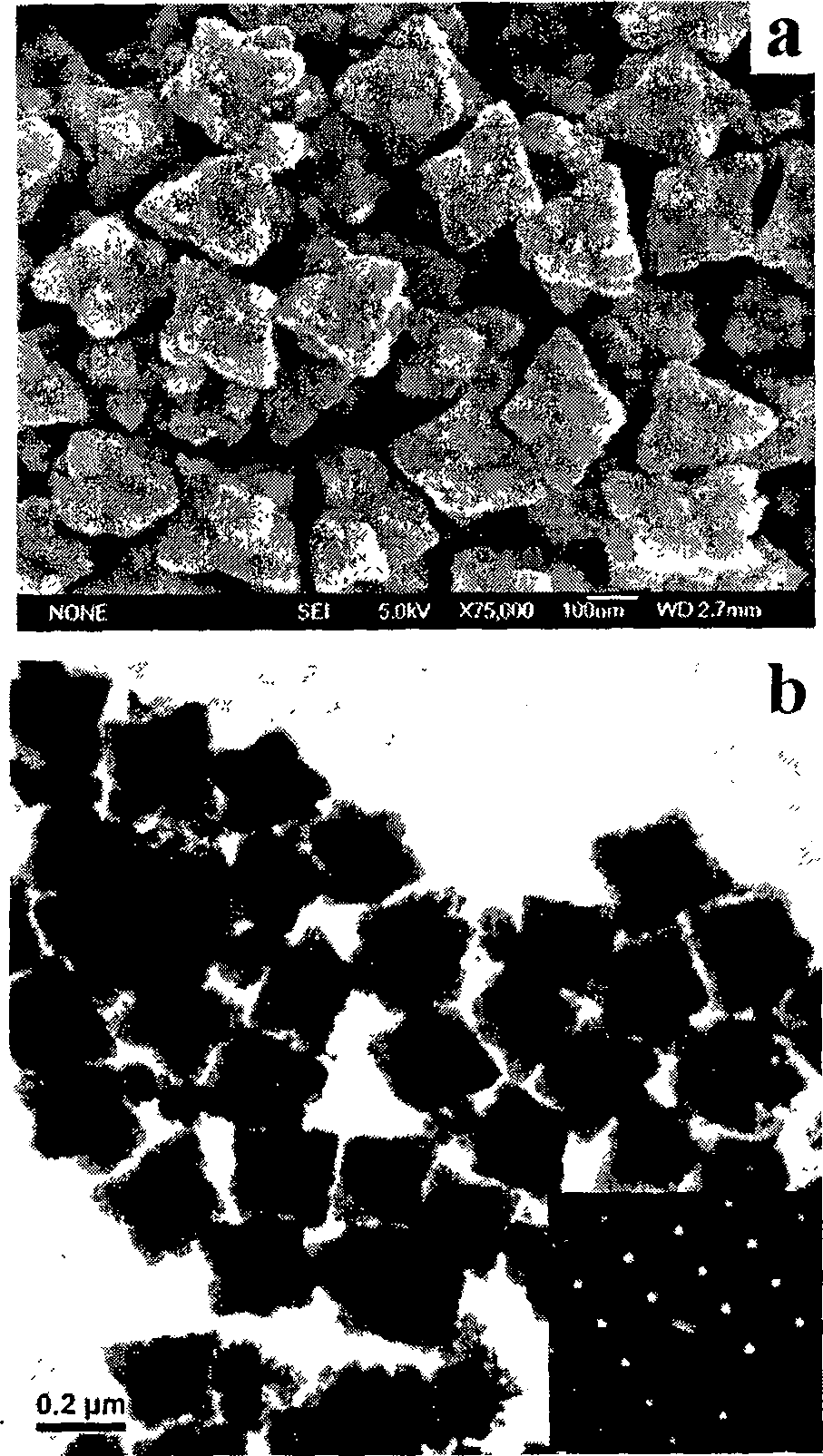

[0020] The X-ray diffraction pattern of the nickel diselenide nanostar of the obtained hexagonal shape is as follows figure 1 a. Depend on figure 1 a It can be seen that the prepared material is nickel diselenide in cubic crystal form. figure 1 b is the energy dispersive X-ray analysis spectrum of the hexagonal nickel diselenide nanostar. It can be seen ...

Embodiment 2

[0022] ①In a 100ml beaker, add 1mmol of nickel acetylacetonate and 5ml of oleic acid into 35ml of anisole, stir magnetically for 30 minutes and then add 2mmol of selenium powder to prepare a reaction solution of nickel diselenide.

[0023] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50ml polytetrafluoroethylene liner. After solvent heating at 200°C for 12 hours, the reactor is naturally cooled to room temperature, centrifuged, and washed with absolute ethanol for several Once, the samples were vacuum-dried. Then hexagonal nickel diselenide nanostars with slightly larger size can be obtained.

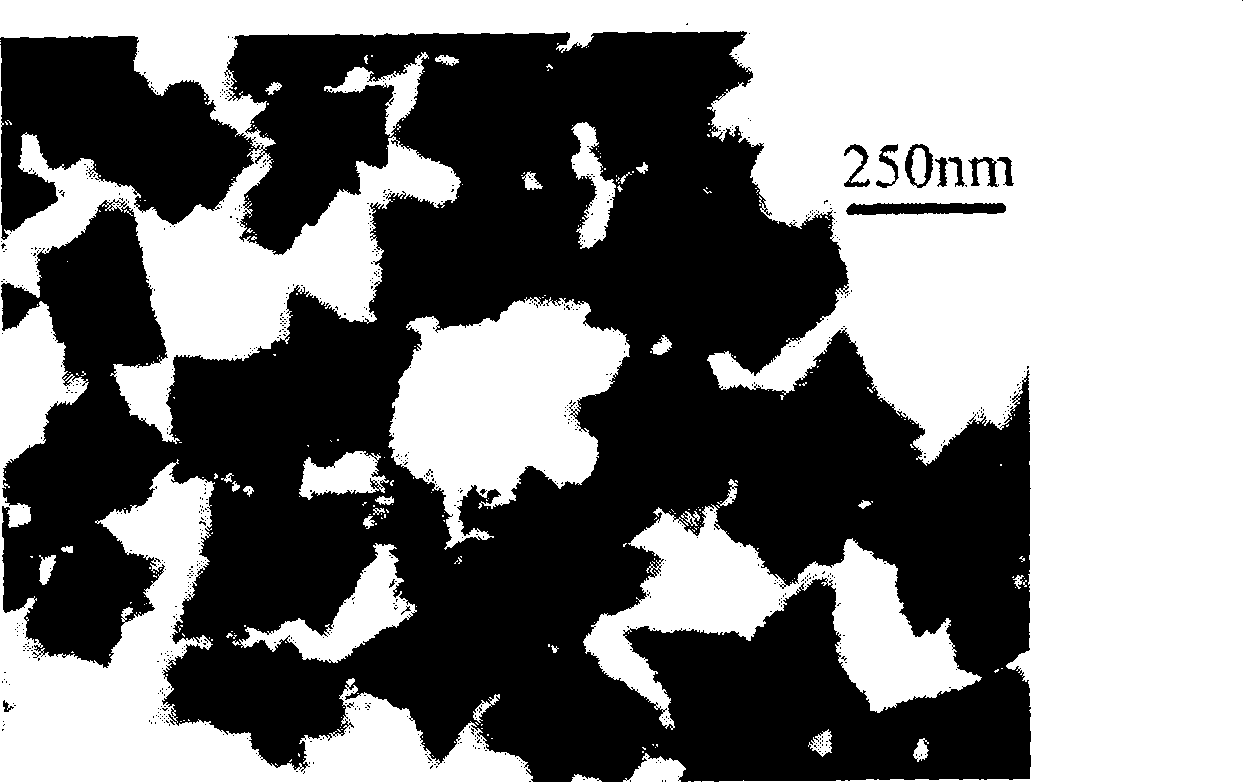

[0024] image 3 It is a transmission electron microscope photo of the hexagonal nickel diselenide nanostar obtained under the condition of solvent heat treatment at 200°C for 12 hours. It can be seen from the figure that the distance between the two symmetrical corners of the hexagonal nickel diselenide nanostar increases to 300nm.

Embodiment 3

[0026] ①In a 100ml beaker, add 0.4mmol of nickel acetylacetonate and 2ml of oleic acid to 38ml of anisole, stir magnetically for 30 minutes and then add 0.8mmol of selenium powder to prepare the reaction of nickel diselenide liquid.

[0027] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50ml polytetrafluoroethylene liner, heat it in a solvent at 160°C for 8 hours, then cool the reactor to room temperature naturally, centrifuge, and wash with absolute ethanol for several Once, the samples were vacuum-dried. The nickel diselenide nanostars with hexagonal shape can be obtained. Figure 4 It is the field emission scanning electron micrograph of the hexagonal nickel diselenide nanostar obtained in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com