Printable flexible conductive paste as well as conductive line and preparation method thereof

A flexible conductive and paste technology, applied in the direction of printed circuits, printed circuit components, conductive materials dispersed in non-conductive inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

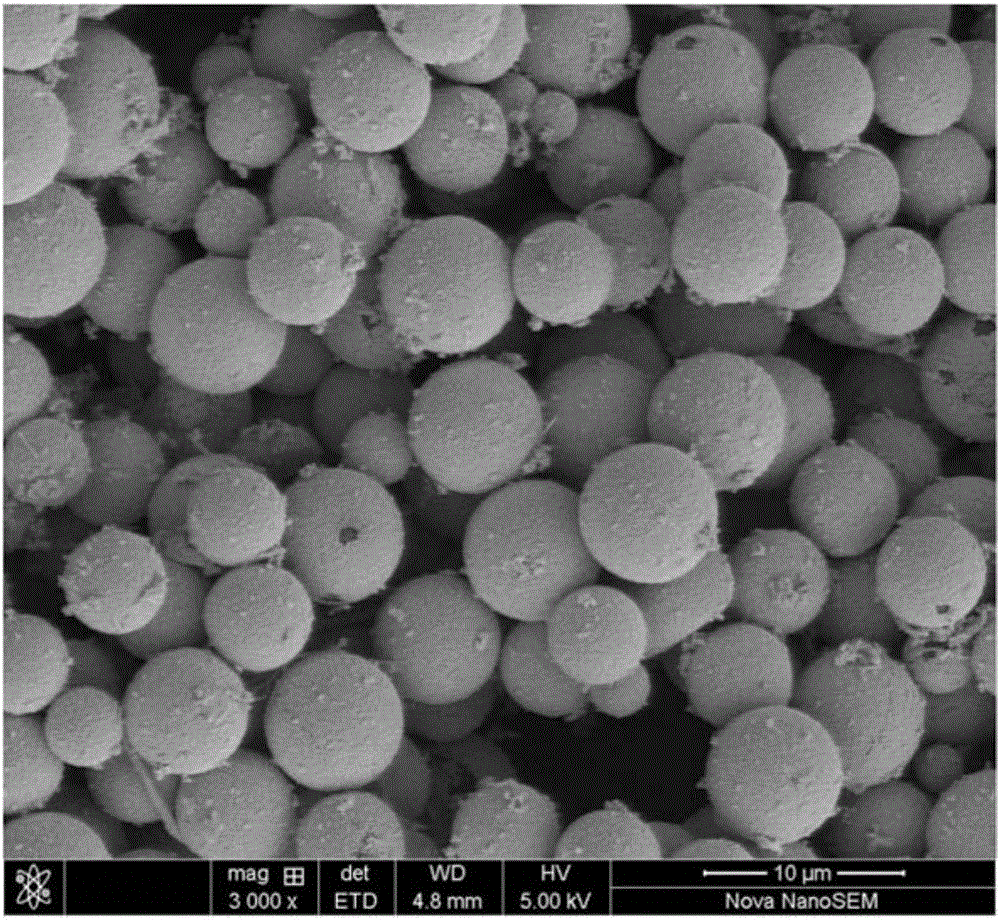

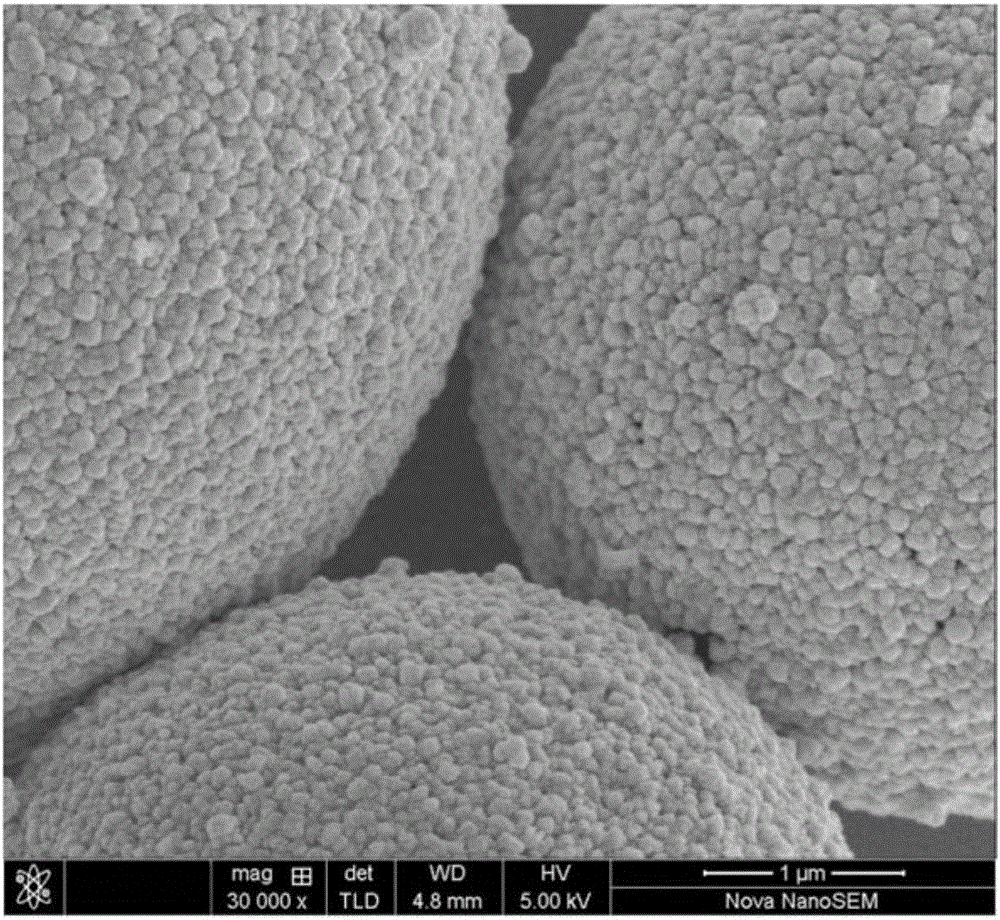

[0094] (1) Synthesis of composite conductive particles

[0095] With polystyrene microspheres with an average particle size of about 5.5 μm as the core, the surface is plated with silver by an electroless plating process to obtain silver-plated conductive particles (such as figure 1 and figure 2 shown). The preparation steps of silver-plated conductive particles are as follows: i) coarsening: 1 gram of styrene microsphere powder is added in a beaker, and 20 milliliters of concentration is added into the beaker as 98% concentrated sulfuric acid, and the beaker is placed in an ultrasonic device to ultrasonically make the polymer Styrene powder was uniformly dispersed in concentrated sulfuric acid, then the beaker was transferred to a water bath at 50°C, reacted for 4 hours under magnetic stirring, washed with deionized water, and then made into a 200mL 5mg / mL aqueous dispersion; ii) sensitive Chemicalization: Add 200mL 5mg / mL coarse polystyrene microsphere aqueous dispersion ...

Embodiment 2

[0100] (1) Synthesis of composite conductive particles

[0101] The polystyrene microsphere with an average particle diameter of about 1 μm is used as the core, and the surface is plated with silver by an electroless plating process to obtain silver-plated conductive particles.

[0102] (2) Preparation of mixed slurry of silver-plated conductive particles and PDMS flexible polymer

[0103] Add silver-plated polystyrene conductive particles to the mixture of PDMS prepolymer and its curing agent (the mass ratio of conductive particles to PDMS is 7:3), rotate and mix at a high speed at room temperature, and then vacuumize and debubble for 30 minutes to obtain Flexible conductive paste. The above slurry was printed on substrates of different materials such as glass, polyethylene terephthalate (PET) film, A4 paper, etc. by metal mask scraping technology, and heated at 80°C for 4h to print The slurry is cured and formed to form a flexible conductive circuit. After testing and cal...

Embodiment 3

[0105] (1) Synthesis of composite conductive particles

[0106] The polystyrene microsphere with an average particle diameter of about 1 μm is used as the core, and the surface is plated with silver by an electroless plating process to obtain silver-plated conductive particles.

[0107] (2) Preparation of mixed slurry of silver-plated conductive particles and PDMS flexible polymer

[0108] Silver-plated polystyrene conductive particles were added to the mixture of PDMS prepolymer and its curing agent (the mass ratio of conductive particles to PDMS was 1:1), mechanically stirred and mixed evenly at room temperature, and then vacuumed to remove air bubbles for 30 minutes to obtain Flexible conductive paste. Print the above paste on substrates of different materials such as glass, stainless steel sheet, plastic, rubber, A4 paper, etc. by screen printing technology, and leave it at room temperature for 24 hours to cure the printing paste to form a flexible conductive circuit. . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com