Preparation method of aptamer sensor for pesticide detection

An aptamer sensor and aptamer technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems affecting the stability, sensitivity and selectivity of aptamer sensors, and it is difficult to meet low residue and quantitative detection, enzyme inhibition The recovery rate of the method is low, and the effect of promoting the transfer of electrons, wide detection range and high sensitivity is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 conductive carbon black-chitosan nanocomposite liquid

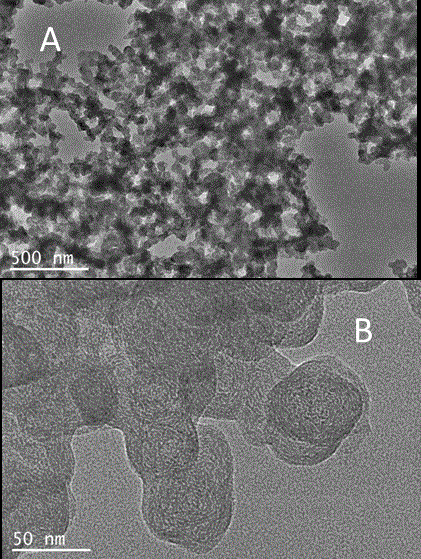

[0044] Dissolve chitosan (CS) in 1.0% acetic acid solution, prepare 0.5% CS solution, stir magnetically at room temperature until chitosan is completely dissolved, dissolve 1.0 mg conductive carbon black powder in 1.0 mL of the above CS solution, and ultrasonically Disperse until a uniformly dissolved composite solution is obtained, figure 1 It is the transmission electron microscope image of the conductive carbon black-chitosan composite, A is a low-magnification scanning image, and B is a high-magnification projection image;

Embodiment 2

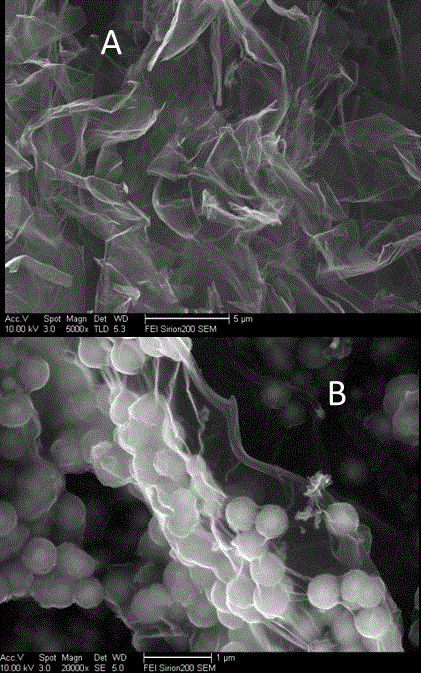

[0045] Example 2 Preparation of graphene oxide-ferric oxide composite

[0046] Graphene oxide is prepared by the improved Hummers method, and the specific preparation steps are as follows: adding graphite powder to H 2 SO 4 (12mL), K 2 S 2 o 8 (2.5 g), P 2 o 5 (2.5 g) in a mixed solution at 80°C for 4.5 h, then diluted with 0.5 L of water, filtered and washed to remove excess acid, and the resulting pre-product was dried overnight at room temperature, and then the pre-oxidized graphite was added to H 2 SO 4 (120 mL), gradually add KMnO 4 (15 g), the mixture was stirred and reacted at 35°C for 30 min, and reacted at 90°C for 90 min, diluted with 250 mL of water, allowed to boil for 25 min, stirred for another 2 hours, added 0.7 L of water and 20 mL of 30%H 2 o 2 solution to terminate the reaction, the mixture was filtered and rinsed several times with 1:10 dilute hydrochloric acid, and then rinsed with water to neutrality, and then the resulting product was furth...

Embodiment 3

[0047] Example 3 Cleaning, activation and testing of glassy carbon electrodes

[0048] Before modification, the glassy carbon electrode was immersed in hot "piranha" solution (H 2 SO 4 : H 2 o 2 = 3:1) for 15 min, rinsed with water, and then 0.3 µm, 30 nm Al 2 o 3 Polish the slurry on the suede to a mirror surface, wash with deionized water after polishing to remove surface dirt, and then use 6 mol / L HNO 3 , absolute ethanol, and deionized water were ultrasonically cleaned for 5 min, and dried under nitrogen atmosphere.

[0049] Activation of the glassy carbon electrode: After thorough cleaning, the electrode was heated at 0.5 mol / L H 2 SO 4 The solution was activated by cyclic voltammetry, the scanning range was 1.0 V~-1.0 V, and the scanning was repeated until a stable cyclic voltammetry was achieved.

[0050] Test of pretreated glassy carbon electrodes: in the presence of 1×10 -3 mol / L K 3 Fe(CN) 6 0.20 mol / L KNO 3 Run the cyclic voltammetry curve in the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com