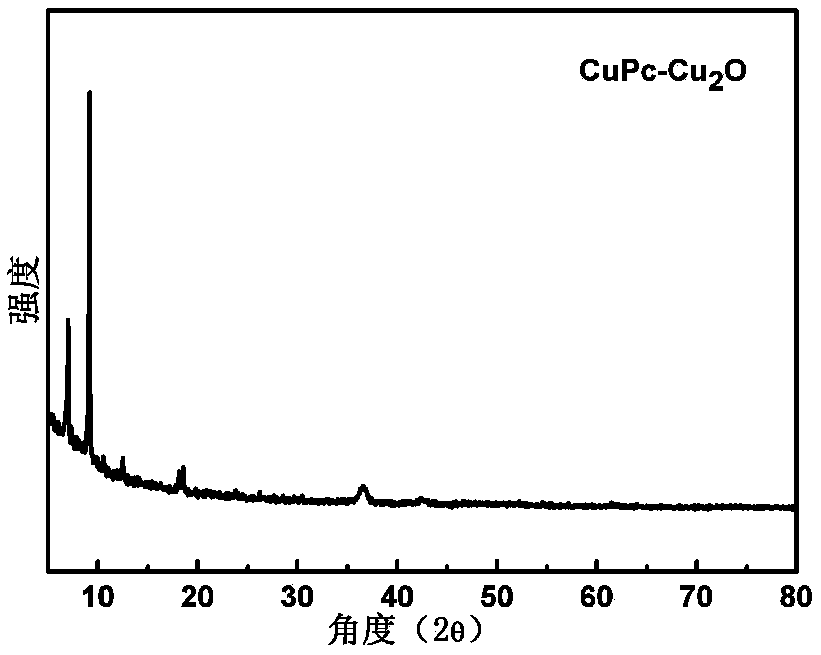

Copper phthalocyanine-cuprous oxide composite gas sensor and preparation method thereof

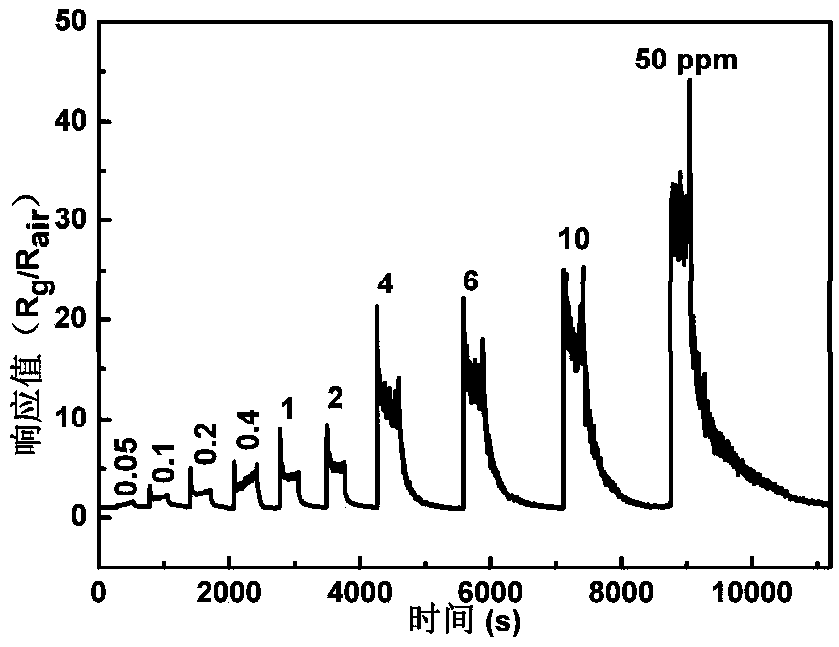

A cuprous oxide and gas sensor technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to accurately control the film thickness of gas-sensitive materials, inability to obtain trimethylamine detection sensitivity, and low product detection sensitivity. Accurate control of film thickness, fast response and recovery time, good reversibility and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete steps of preparation are:

[0045] In step 1, copper phthalocyanine is first placed in a sulfuric acid solution with a mass fraction of 99% at 30°C and stirred until it is completely dissolved to obtain a copper phthalocyanine sulfuric acid solution. Then, according to the volume ratio of copper phthalocyanine sulfuric acid solution and deionized water of 1:8, the copper phthalocyanine sulfuric acid solution was added into deionized water at 90° C., stirred for 5 hours, and then filtered to obtain a filter cake.

[0046]In step 2, first place the filter cake in 0.08 mol / L acid solution and alkali solution to disperse and then suction filter; wherein, the acid solution is hydrochloric acid solution, and the alkali solution is sodium hydroxide solution to obtain purified copper phthalocyanine. Then, the purified copper phthalocyanine was washed with deionized water until the filtrate was neutral, and then dried at 60° C. to obtain copper phthalocyanine nanoro...

Embodiment 2

[0050] The concrete steps of preparation are:

[0051] In step 1, copper phthalocyanine is first placed in a sulfuric acid solution with a mass fraction of 98% at 40°C and stirred until it is completely dissolved to obtain a copper phthalocyanine sulfuric acid solution. According to the volume ratio of copper phthalocyanine sulfuric acid solution and deionized water of 1:9, the copper phthalocyanine sulfuric acid solution was added to deionized water at 93° C., stirred for 4.5 hours, and then filtered to obtain a filter cake.

[0052] In step 2, first place the filter cake in 0.09 mol / L acid solution and alkali solution to disperse and then suction filter; wherein, the acid solution is hydrochloric acid solution, and the alkali solution is sodium hydroxide solution to obtain purified copper phthalocyanine. Then, the purified copper phthalocyanine was washed with deionized water until the filtrate was neutral, and then dried at 70° C. to obtain copper phthalocyanine nanorods. ...

Embodiment 3

[0056] The concrete steps of preparation are:

[0057] Step 1, first place copper phthalocyanine in a sulfuric acid solution with a mass fraction of 97% at 50° C. and stir until it is completely dissolved to obtain a copper phthalocyanine sulfuric acid solution. According to the volume ratio of copper phthalocyanine sulfuric acid solution and deionized water of 1:10, the copper phthalocyanine sulfuric acid solution was added into deionized water at 95° C., stirred for 4 hours, and then filtered to obtain a filter cake.

[0058] In step 2, first place the filter cake in 0.1 mol / L acid solution and alkali solution to disperse and then suction filter; wherein, the acid solution is hydrochloric acid solution, and the alkali solution is sodium hydroxide solution to obtain purified copper phthalocyanine. Then, the purified copper phthalocyanine was washed with deionized water until the filtrate was neutral, and then dried at 80° C. to obtain copper phthalocyanine nanorods.

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com