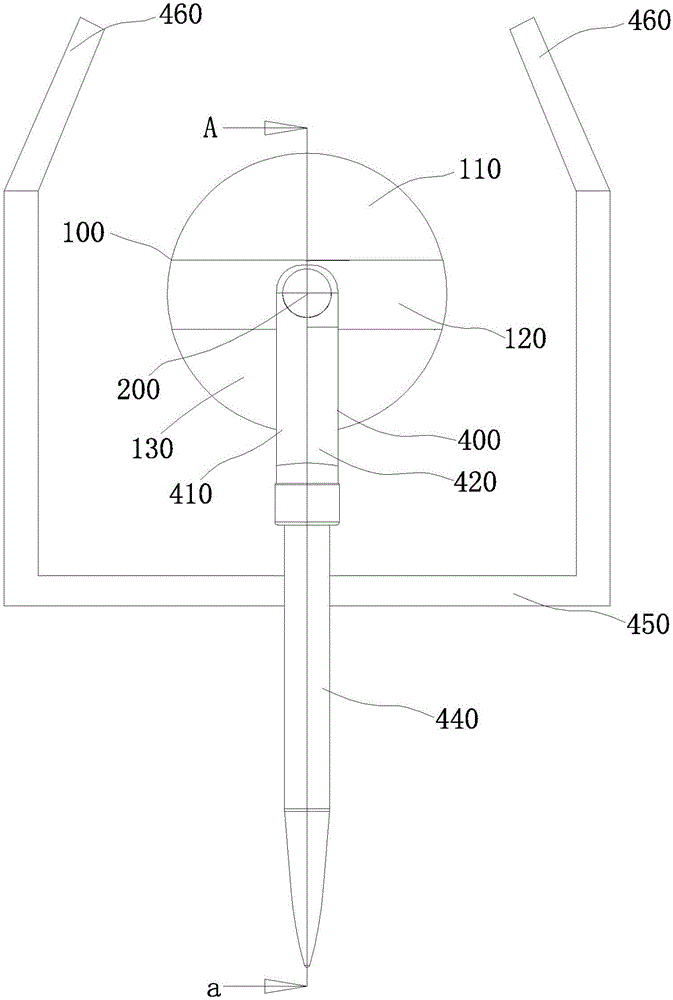

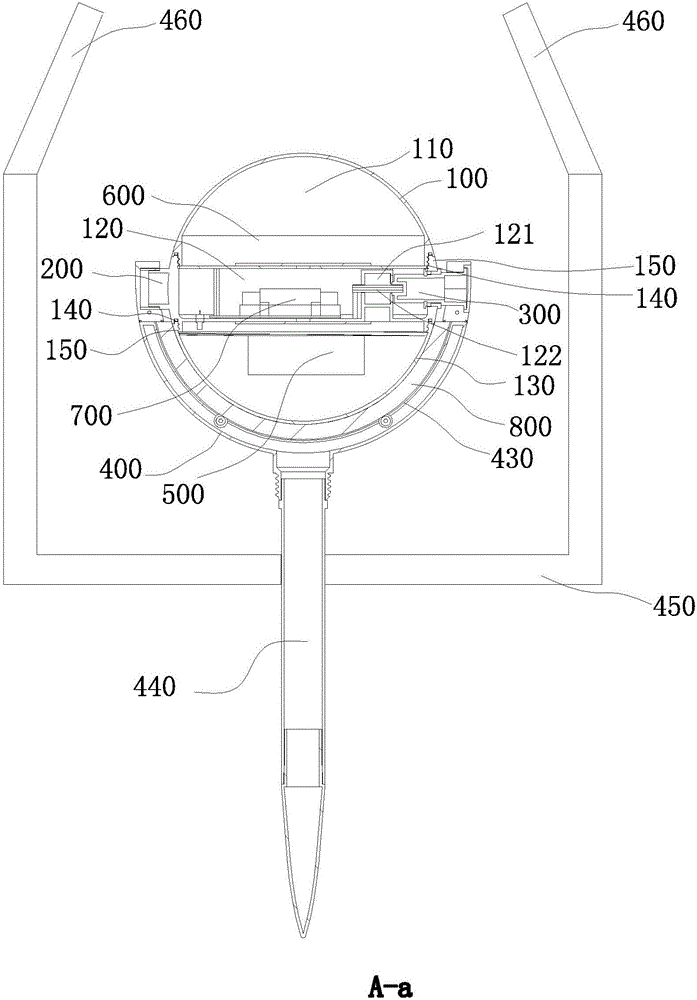

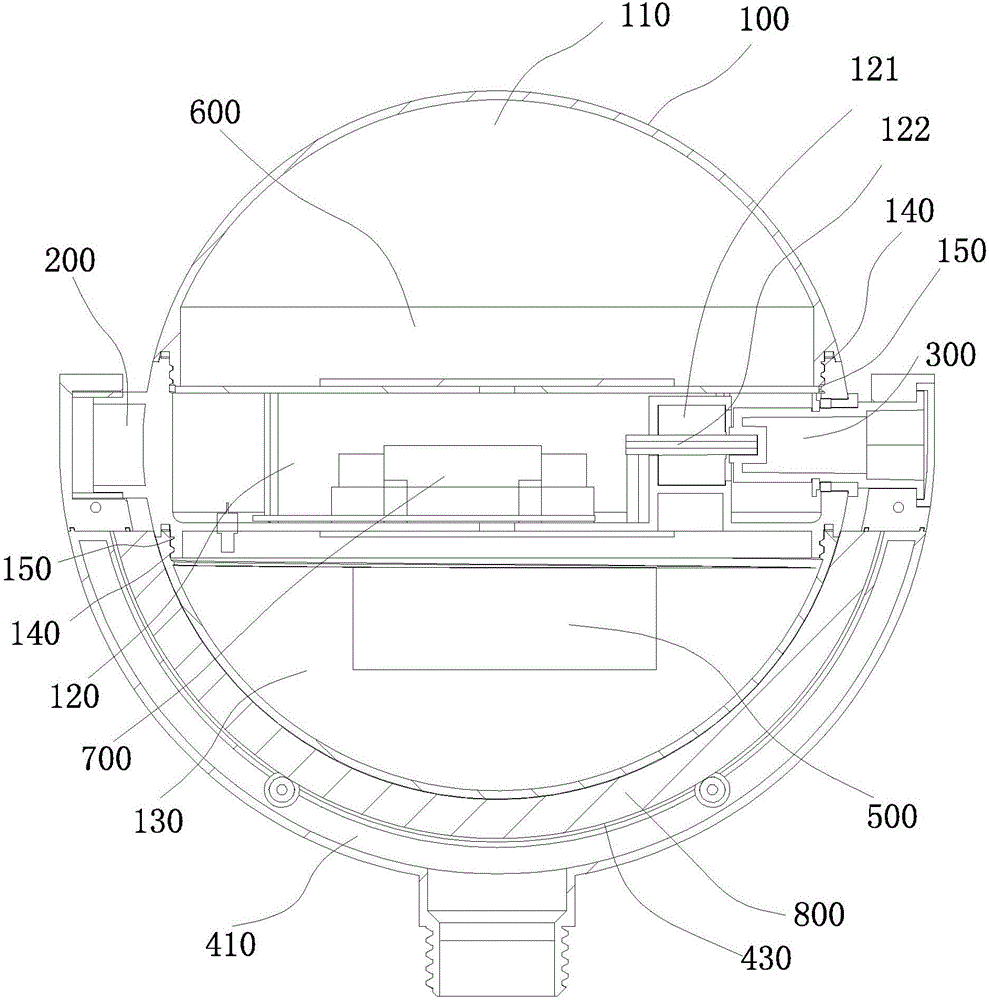

Spherical solar power lamp

A kind of solar energy and spherical technology, which is applied to the damage prevention measures of lighting devices, lighting and heating equipment, cleaning methods and appliances, etc., which can solve the problem of inability to take into account light efficiency and photoelectric conversion efficiency, and cannot conveniently and quickly convert photovoltaic panels and light sources and other problems, to achieve the effect of preventing oxidation, improving strength, and retarding matrix corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Prepare the copper alloy raw material of the photovoltaic battery panel, after melting, rough refining and refining, and then use the nitrogen powder spraying process to make copper powder under the conditions of nitrogen pressure 1.6Mpa, nozzle diameter 4 mm, and air inlet angle 45°; The composition and mass percentage of the copper alloy are: Mn: 0.18%, Al: 0.35%, Si: 0.55%, Sn: 0.42%, Ni: 0.2%, Cr: 0.22%; Zn: 3.3%, and the balance is Cu and unavoidable impurities; the particle size distribution of copper powder is: the content of particles below 50 μm is 10%, the content of 50-100 μm particles is 50%, and the balance is 100-150 μm particles.

[0070] Screen copper powder, mix copper powder with graphite powder and then grind; the particle size of graphite powder is 40-60 μm.

[0071] Sinter the powder at 810°C and process it into a photovoltaic panel blank;

[0072] The finished photovoltaic cell panel can be obtained by heat-treating the blank of the photovoltaic c...

Embodiment 2

[0074] Prepare the copper alloy raw material of the photovoltaic battery panel, after melting, rough refining and refining, and then use the nitrogen powder spraying process to make copper powder under the conditions of nitrogen pressure 1.7Mpa, nozzle diameter 3.5 mm, and air inlet angle 48°; The composition and mass percentage of the copper alloy are: Mn: 0.22%, Al: 0.52%, Si: 0.52%, Sn: 0.36%, Ni: 0.18%, Cr: 0.18%; Zn: 2.8%, and the balance is Cu and unavoidable impurities; the particle size distribution of copper powder is: the content of particles below 50 μm is 12%, the content of 50-100 μm particles is 46%, and the balance is 100-150 μm particles.

[0075] Screen copper powder, mix copper powder with graphite powder and then grind; the particle size of graphite powder is 40-60 μm.

[0076] Sinter the powder at 815°C and process it into a photovoltaic panel blank;

[0077] The finished photovoltaic cell panel can be obtained by heat-treating the blank of the photovoltai...

Embodiment 3

[0079] Prepare the copper alloy raw material of the photovoltaic battery panel, after melting, rough refining and refining, and then use the nitrogen powder spraying process to make copper powder under the conditions of nitrogen pressure 1.8Mpa, nozzle diameter 5 mm, and air inlet angle 50°; The composition and mass percentage of the copper alloy are: Mn: 0.25%, Al: 0.05%, Si: 0.6%, Sn: 0.3%, Ni: 0.25%, Cr: 0.15%; Zn: 3.8%, and the balance is Cu and unavoidable impurities; the particle size distribution of copper powder is: the content of particles below 50 μm is 15%, the content of 50-100 μm particles is 40%, and the balance is 100-150 μm particles.

[0080]The copper powder is screened, and the copper powder and graphite powder are mixed and ground; the particle size of the graphite powder is 60 μm.

[0081] The powder is sintered at 820°C and processed into photovoltaic cell panel blanks.

[0082] The finished photovoltaic cell panel can be obtained by heat-treating the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com