A kind of electroforming preparation method of silver solder with high indium content

A silver brazing material and content technology, applied in the field of welding materials, can solve the problems of large wetted area, low melting point of brazing material, low indium content, etc., and achieve the effects of fast thermal diffusion, firm bonding and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

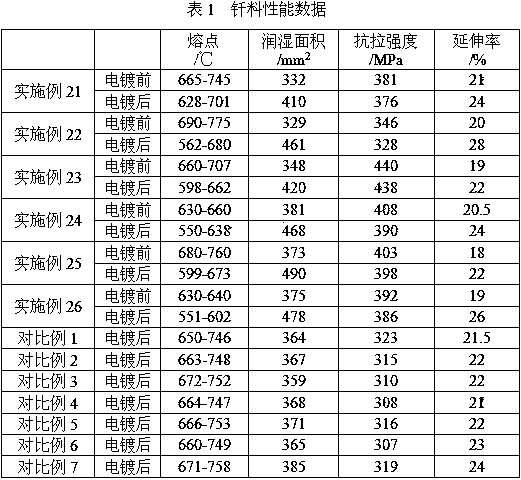

Examples

Embodiment 1

[0021] A preparation method for electroforming of silver solder with high indium content, the specific steps are as follows:

[0022] (1) Electroplating is carried out with silver solder as the cathode and indium plate as the anode. The composition of the electroplating solution is: In 2+ Metal salt 20-130g / L, strong acid 40-120ml / L or medium strong acid 35-65 g / L, additive 2-80 g / L, current density: 2-5A / dm 2 , temperature 30-60°C, pole spacing 15-20mm, stirring speed 350-500r / min, pH=0.6-0.8, electroplating time: 4-15min;

[0023] (2) Diffusion treatment is carried out on the silver solder containing the indium electroplating layer on the surface after electroplating. The diffusion treatment method is as follows: firstly, the solder containing the indium electroplating layer is placed in a high-temperature pipeline at 350-450°C under an argon protective atmosphere, The time is 30-50min; then placed in a tube furnace at 160-180°C, diffused for 6-10h; finally annealed at 450-...

Embodiment 2

[0030] A preparation method for electroforming of silver solder with high indium content, the specific steps are as follows:

[0031] (1) Electroplating is carried out with silver solder as the cathode and indium plate as the anode. The composition of the electroplating solution is: In 2+ Metal salt 20g / L, strong acid 40ml / L, additive 2g / L, current density: 2A / dm 2 , temperature 30°C, pole spacing 15mm, stirring speed 350r / min, pH=0.6, electroplating time: 4min;

[0032] (2) Diffusion treatment is carried out on the silver solder containing indium electroplating layer on the surface after electroplating. The diffusion treatment method is as follows: firstly, the solder containing indium electroplating layer is placed in a high-temperature pipeline at 350°C under an argon protective atmosphere for a time of 30min; then placed in a tube furnace at 160°C, diffused for 6h; finally annealed at 450°C, and then rolled or drawn.

[0033] In step (1), the thickness of the indium plat...

Embodiment 3

[0036] A preparation method for electroforming of silver solder with high indium content, the specific steps are as follows:

[0037] (1) Electroplating is carried out with silver solder as the cathode and indium plate as the anode. The composition of the electroplating solution is: In 2+ Metal salt 30g / L, strong acid 45ml / L, additive 5g / L, current density: 2.2A / dm 2, temperature 32°C, pole spacing 15.5mm, stirring speed 360r / min, pH=0.62, electroplating time: 5min;

[0038] (2) Diffusion treatment is carried out on the silver solder containing indium electroplating layer on the surface after electroplating. The diffusion treatment method is as follows: firstly, the solder containing indium electroplating layer is placed in a high-temperature pipeline at 360°C in an argon protective atmosphere for a time of 32min; then placed in a tube furnace at 162°C, diffused for 6.2h; finally annealed at 455°C, and then rolled or drawn.

[0039] In step (1), the thickness of the indium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com