Low-temperature synthesis method of molybdate fluorescent powder

A synthesis method and fluorescent powder technology, applied in chemical instruments and methods, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

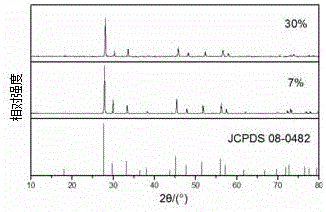

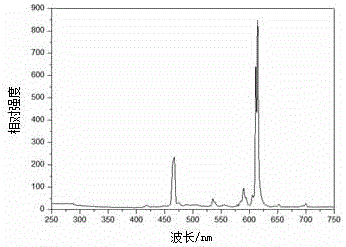

[0049] A method for synthesizing molybdate fluorescent powder at low temperature, comprising the following steps: accurately weighing SrCO3, H2MoO4, Eu2O3 and a certain amount of NH4F, NaF, H3BO3, BaF2, NH4Cl, Li2CO3, Na2CO3 and K2CO3 are used as starting materials, add a small amount of absolute ethanol, and grind for 35-45 minutes in an agate mortar washed with deionized water to fully mix the raw materials, transfer the evenly ground medicine to a crucible and place it in a muffle furnace Calcined in the furnace, after the sample is cooled to room temperature with the furnace, grind it evenly in the agate mortar again.

[0050] Following is the composition of each raw material among the embodiment 1-9:

[0051] The weight percent of each raw material in the sample of Table 1 Example 1-9 (wherein the main material is SrCO3, H2MoO4 and Eu2O3):

[0052]

[0053] Raw material mol SrCO 3

h 2 MoO 4

Eu 2 o 3

Example 1 0.7 1 0.3 Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com