White polyolefin glue film with good water resistance performance, and preparation method thereof

A technology for encapsulating adhesive films and polyolefins, which can be used in adhesives, film/sheet adhesives, photovoltaic power generation, etc., which can solve the problem of prolonging the power generation cycle of solar double-glass modules, reducing the service life of double-glass modules, and increasing potential-induced attenuation. Probability and other issues, to achieve excellent anti-ultraviolet performance, reduce water vapor transmission rate, difficult to move and diffuse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

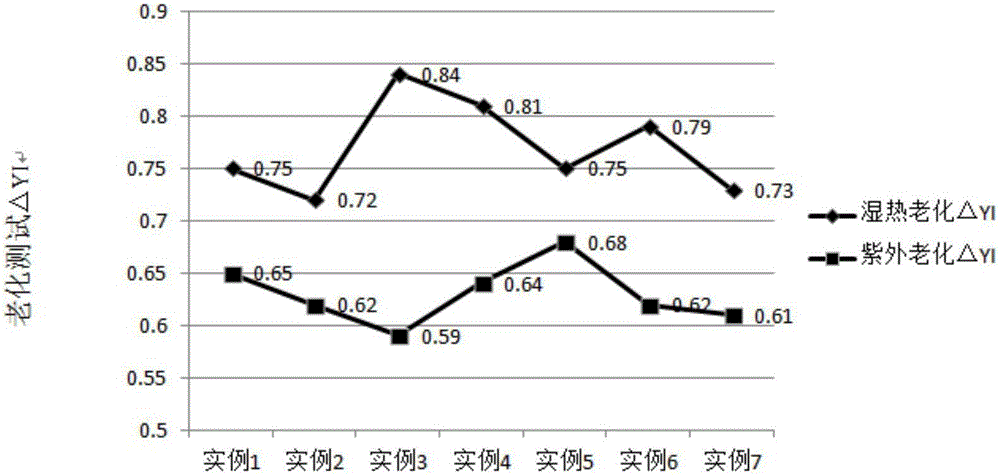

Examples

Embodiment 1

[0039] A white polyolefin encapsulating adhesive film with good water-blocking performance, comprising the following components in parts by weight: 100 parts of polyolefin resin A with a melt index of 3 g / 10 min and a melting point of 115°C; 20 parts of a melt index of 10 g / 10 min , polyolefin resin B with a melting point of 100°C; 2.0 parts of carbaperoxyacid-O,O-(1,1-dimethylethyl)-O-(2-ethylhexyl) ester, 0.6 parts of triallyl Base isocyanurate, 0.8 parts of vinyltriethoxysilane, 25 parts of color masterbatch, 0.4 parts of bis(2,2,6,6-tetramethyl-4-piperidinol) sebacate, 0.6 parts of [2-hydroxy-4-(octyloxy)phenyl] phenyl ketone, mix the above components evenly through the mixing tank, put them into the casting machine and set the parameters, after plasticizing extrusion, casting , traction, and winding to make a white polyolefin encapsulation film for solar cells with high water resistance.

[0040]Wherein, the color masterbatch is a mixture of 40% titanium dioxide and 60% ...

Embodiment 2

[0042] A white polyolefin encapsulating adhesive film with good water blocking performance, comprising the following components in parts by weight: 100 parts of polyolefin resin A with a melting index of 10 g / 10 min and a melting point of 105°C; 25 parts of a polyolefin resin A with a melting index of 15 g / 10 min , polyolefin resin B with a melting point of 90°C; 1.5 parts of tert-butyl peroxycarbonate-2-ethylhexyl, 0.8 parts of triallyl isocyanurate, 0.7 parts of ethylene triethoxysilane, 22 1 part of masterbatch, 0.1 part of bis(2,2,6,6-tetramethyl-4-piperidinol) sebacate, 0.5 part of [2-hydroxy-4-(octyloxy)phenyl]benzene Base ketone, mix the above components evenly through the mixing tank, put them into the tape casting machine and set the parameters, after plasticizing extrusion, casting, pulling, and winding, it is made into a white high-resistance polyolefin for solar cells Packaging film.

[0043] Wherein, the color masterbatch is a mixture of 46% titanium dioxide and ...

Embodiment 3

[0045] A white polyolefin encapsulating adhesive film with good water-blocking performance, comprising the following components in parts by weight: 100 parts of polyolefin resin A with a melt index of 15 g / 10 min and a melting point of 95°C; 30 parts of a melt index of 25 g / 10 min , polyolefin resin B with a melting point of 80°C; 1.2 parts of tert-butyl peroxy 2-ethylhexyl carbonate, 1.0 parts of 1,3,5-tri-2-propenyl-1,3,5-triazine -2,4,6(1H,3H,5H)-trione, 0.6 parts of triethoxyethylene silane, 20 parts of masterbatch, 0.3 parts of bis(2,2,6,6-tetramethyl-4- Piperidinol) sebacate, 0.4 parts of [2-hydroxy-4-(octyloxy) phenyl] phenyl ketone, mix the above components evenly through the mixing tank, put them into the casting machine and set the parameters , after plasticizing extrusion, casting, pulling, and winding, it is made into a white polyolefin encapsulation film for solar cells with high water resistance.

[0046] Wherein, the color masterbatch is a mixture of 52% titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com