PVC (polyvinyl chloride) coating cured by using UV (ultraviolet)-LED (light-emitting diode) light source and preparation method of PVC coating

A UV-LED, light source technology, used in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of short service life of high-pressure mercury lamps, substrate deformation, equipment corrosion, etc., and achieve broad market application prospects , The effect of preventing oxygen inhibition and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

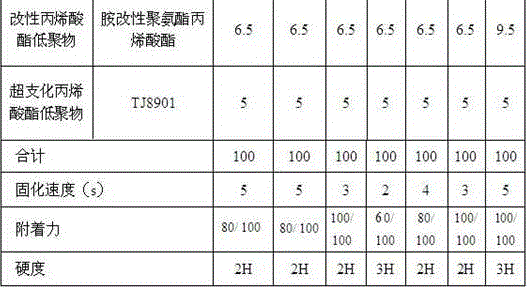

[0025] The invention will be further illustrated by the following non-limiting examples.

[0026] The present invention also provides a kind of preparation method of the PVC coating composition cured by UV-LED light source, comprises the following steps:

[0027] Step 1, under the condition of avoiding sunlight or ultraviolet light, mix polyurethane acrylate, hyperbranched acrylate oligomer, some monomers, and photoinitiator in sequence according to the ratio, and control the temperature of the mixed material during the stirring process When the temperature is less than 50°C, the stirring speed is 500-8000 rpm for 5 minutes;

[0028] Step 2: Add fillers and pigments according to the above ratio, fully disperse at a stirring speed of 800-1000 rpm, then add additives to disperse evenly, and finally add amine-modified acrylate oligomer and remaining monomers and stir at room temperature and adjust the viscosity. After uniform dispersion, the PVC coating cured by UV-LED light so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com