Method for preparing cement mortar with photocatalysis function from red mud solid wastes

A technology of cement mortar and photocatalysis, which is applied in the field of cement mortar to achieve important social and economic benefits, reduce pollution, and improve air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Granular Red Mud

[0024] (1) Weigh 100kg of red mud solid waste and sinter at 550°C for 3.5 hours;

[0025] (2) Pulverize the red mud solid waste sintered in step (1), and pass through a 100-120-mesh sieve, so that the particle size is 0.12mm-0.15mm to obtain granular red mud.

Embodiment 2

[0027] The photocatalytic functional cement mortar is prepared by using red mud, which is suitable for engineering plastering construction.

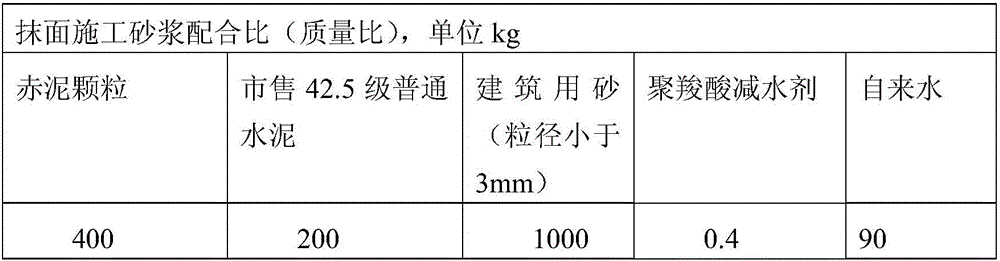

[0028] The heat-treated red mud prepared by the method in Example 1 is used as raw material, and the specific raw material mixing ratio is shown in Table 1.

[0029] Catalyst performance evaluation is achieved by the following devices:

[0030] Reactor: airtight ventilation pipe, filled with 2 pieces of cement mortar in the middle, and an ultraviolet lamp is installed on the top of the device. Take formaldehyde, benzene, toluene, and nitric oxide as simulated gas pollutants, collect air samples at the inlet and outlet sampling points every 30 minutes, test the concentration of pollutants, calculate the average value, and calculate the primary purification efficiency of the photocatalyst for gas pollutants .

[0031] The gas flow rate is 1.00L / min and 2.00L / min, the temperature is room temperature, and the air humidity is 50±5%.

[003...

Embodiment 3

[0036] The photocatalytic functional cement mortar is prepared by using red mud, which is suitable for engineering plastering construction.

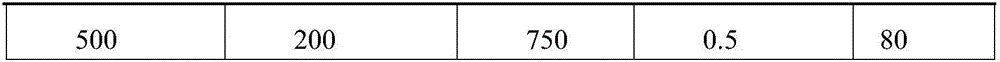

[0037] The heat-treated red mud prepared by the method in Example 1 was used as raw material, and the specific raw material mixing ratio is shown in Table 2.

[0038] The photocatalytic functional mortar was tested as in Example 2, and the catalytic effect evaluation is shown in Table 7.

[0039] Table 2:

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com