A kind of method that utilizes steel slag to prepare the cement mortar with photocatalytic degradation NOX

A technology of cement mortar and photocatalysis, applied in the field of cement mortar, to achieve the effects of promoting sustainable development, solving the problem of solid waste recycling, and important social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Heat treatment of steel slag to obtain high content of α-Fe 2 o 3

[0019] (1) Take 100kg of steel slag, put it in a ball mill and grind it until the average particle size is less than 0.2mm, and the fineness modulus is 0.6-1.3;

[0020] (2) Heat-treat the ground steel slag at 850°C for 5 hours to make Fe 3 o 4 Phase change to α-Fe 2 o 3 .

Embodiment 2

[0022] The photocatalytic NOx degradation cement mortar is prepared by using steel slag, which is suitable for engineering plastering construction.

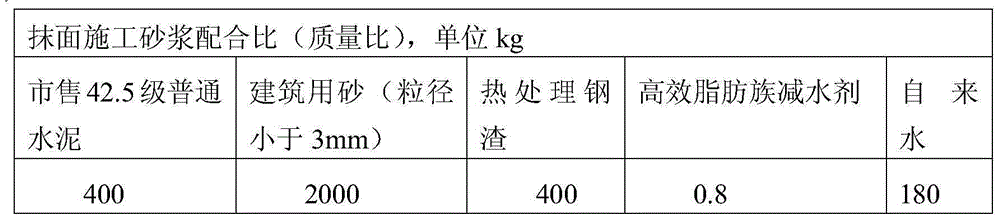

[0023] The heat-treated steel slag obtained by the method of Example 1 is used as raw material, and the specific raw material mixing ratio is shown in Table 1.

[0024] Table 1:

[0025]

Embodiment 3

[0027] The photocatalytic NOx degradation cement mortar is prepared by using steel slag, which is suitable for engineering plastering construction.

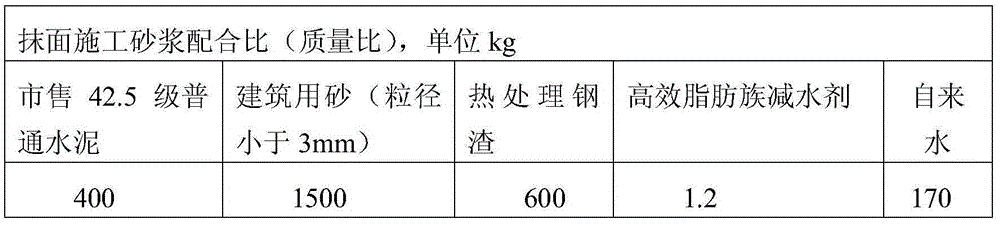

[0028] The heat-treated steel slag obtained by the method of Example 1 is used as a raw material, and the specific raw material mixing ratio is shown in Table 2.

[0029] Table 2:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com