Sound-absorption sound-insulation needle-punched nonwoven fabric for automotive interiors and preparation method thereof

A technology of needle-punched non-woven fabrics and automotive interiors, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve the problem that the sound insulation effect cannot meet the requirements, reduce energy consumption, increase surface density, save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

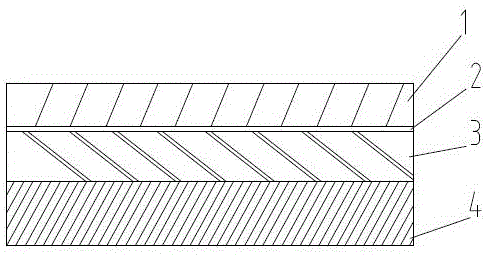

[0026] A sound-absorbing and sound-insulating needle-punched non-woven fabric for automobile interior decoration, characterized in that it includes a face cloth 1 and a base cloth, the face cloth 1 and the base cloth are connected by an adhesive layer 2, and the face cloth 1 is 1.5D-8D polyester fiber, the surface density is 250-400g / ㎡, the base fabric includes the first base fabric 3 and the second base fabric 4, the first base fabric 3 and the second base fabric 4 They all include a fineness of 1.5D-8D, 30-40 parts by mass of polyester fiber, 25-35 parts of waste cotton fiber, 15-20 parts of polypropylene fiber and 15-20 parts of low-melting fiber. The surface density of the first base cloth 3 is 500-600g / ㎡, and the acupuncture density is 150-200 needles / cm²; the surface density of the second base fabric 4 is 800-900g / ㎡, and the needle density is 350-500 needles / cm². cm²; the first base fabric 3 and the second base fabric 4 are needle-punched and composited, and the needle-p...

Embodiment 2

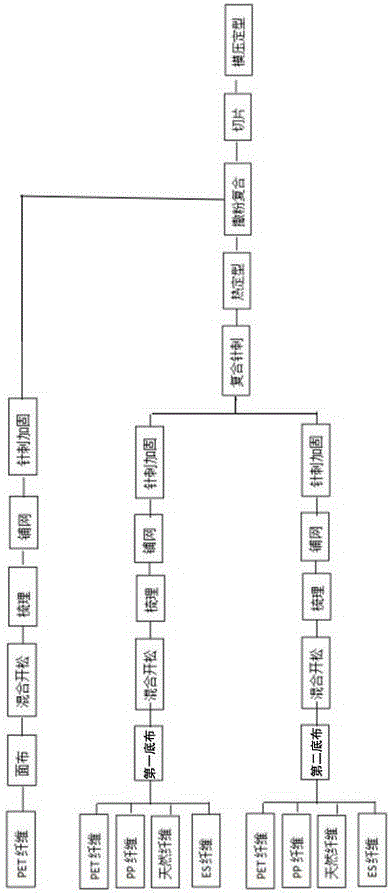

[0028] A preparation method of sound-absorbing and sound-insulating needle-punched nonwoven fabric for automotive interior:

[0029] Step 1: Mixing, opening, carding, laying, and needle-punching polyester fibers of 1.5D-8D to make face cloth 1;

[0030] Step 2: Mix 30-40 parts of polyester fiber, 25-35 parts of waste cotton fiber, 15-20 parts of polypropylene fiber, and 15-20 parts of low-melting point fiber according to the proportion, carding, laying, and acupuncture reinforcement to make the bottom cloth;

[0031] Step 3: The base fabric includes a first base fabric 3 and a second base fabric 4, and the first base fabric 3 and the second base fabric 4 are needle-punched and compounded;

[0032] Step 4: heat setting: heat and shape the compounded first base fabric 3 and second base fabric 4 through a setting machine, and the setting temperature is 160-180°;

[0033] Step 5: Powder compounding: the heat-set first base cloth 3 and the second base cloth 4 are bonded to the fa...

Embodiment 3

[0035] A sound-absorbing and sound-insulating needle-punched non-woven fabric for automobile interior decoration, characterized in that it includes a face cloth 1 and a base cloth, the face cloth 1 and the base cloth are connected by an adhesive layer 2, and the face cloth 1 is 1.5D-8D polyester fiber, the surface density is 250-400g / ㎡, the base fabric includes the first base fabric 3 and the second base fabric 4, the first base fabric 3 and the second base fabric 4 They all include a fineness of 1.5D-8D, 30-40 parts by mass of polyester fiber, 25-35 parts of waste cotton fiber, 15-20 parts of polypropylene fiber and 15-20 parts of low-melting fiber. The surface density of the first base cloth 3 is 500-600g / ㎡, and the acupuncture density is 150-200 needles / cm²; the surface density of the second base fabric 4 is 800-900g / ㎡, and the needle density is 350-500 needles / cm². cm²; the first base fabric 3 and the second base fabric 4 are needle-punched and composited, and the needle-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com