Air sterilizing disinfectant

A disinfectant and raw material technology, applied in the direction of disinfectant, biocide, application, etc., can solve the problems of restricting the widespread use of chlorine dioxide, chlorine dioxide is acidic, and limited use range, etc., to achieve low production cost and less production equipment , high social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

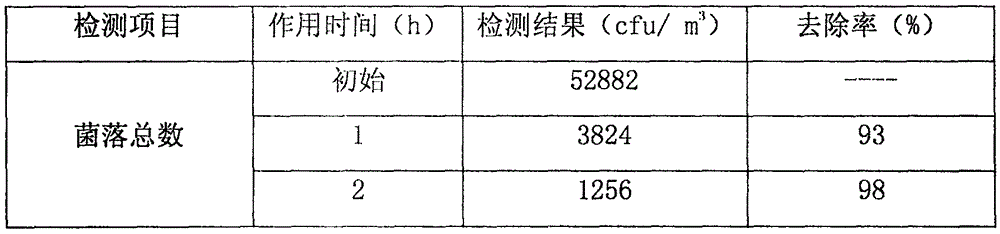

Examples

Embodiment 1

[0031] Weigh 20g of sodium chlorite, 20g of sodium dichloroisocyanurate, 5g of boric acid, 8g of sodium bicarbonate, 5g of sodium carboxymethyl starch, 30g of sodium bisulfate, 15g of anhydrous sodium sulfate, and 5g of polyethylene glycol 6000, Mix sodium chlorite with sodium bicarbonate and anhydrous sodium sulfate for 1 () minute, then add sodium dichloroisocyanurate, polyethylene glycol 6000 and sodium carboxymethyl starch into the above mixture and mix for 15 minutes, and finally add Boric acid and sodium bisulfate were mixed and left for 25 minutes, and the mixture was prepared into 100 tablets.

Embodiment 2

[0033] Weigh 25g of sodium chlorite, 12g of sodium dichloroisocyanurate, 5g of boric acid, 15g of sodium bicarbonate, 5g of sodium carboxymethyl starch, 30g of sodium bisulfate, 20g of anhydrous sodium sulfate, and 8g of polyethylene glycol 6000, Mix sodium chlorite with sodium bicarbonate and anhydrous sodium sulfate for 15 minutes, then add sodium dichloroisocyanurate, polyethylene glycol 6000 and sodium carboxymethyl starch into the above mixture and mix for 10 minutes, finally add boric acid and Sodium bisulfate was mixed therein and left for 30 minutes, and the mixture was prepared into 100 tablets.

Embodiment 3

[0035] Weigh 10g of sodium chlorite, 25g of sodium dichloroisocyanurate, 1g of citric acid, 15g of sodium carboxymethyl starch, 40g of sodium lauryl sulfate, 10g of anhydrous sodium sulfate, and 3g of polyethylene glycol 6000. Mix sodium chlorite with sodium bicarbonate and anhydrous sodium sulfate for 18 minutes, then add sodium dichloroisocyanurate, polyethylene glycol 6000 and sodium carboxymethyl starch into the above mixture and mix for 15 minutes, and finally add boric acid and sulfuric acid Sodium hydrogen was mixed therein and left for 20 minutes, and the mixture was prepared into 100 tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com