Method for preparing vasopressin deamidization impurities

A technology for deamidation and impurities, applied in the field of biopharmaceuticals, can solve the problems of dilute sample concentration, low yield and large volume, and achieve the effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 (HPLC method to detect the crude product of vasopressin deamidation impurity precursor and the purity of the purified product solution)

[0031] Instrument: Waters 2695 / 2489 high performance liquid chromatography

[0032] Separation column: Agilent XDB-C18 4.6×250mm, 5μm

[0033] Mobile phase: A is 0.1% TFA aqueous solution in volume percentage, B is 0.1% TFA-50% acetonitrile aqueous solution in volume percentage (TFA is trifluoroacetic acid)

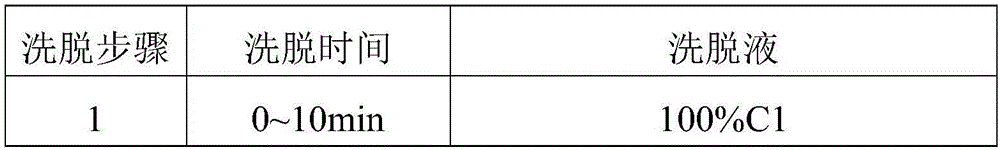

[0034] The flow rate is 1.0mL / min, the detection wavelength is 214nm, and it is detected at room temperature. The elution gradient is shown in the table below, and the percentages are volume percentages.

[0035] Elution step Elution time eluent 1 0~5min 95%A+5%B 2 5~25min 95%A+5%B→50%A+50%B 3 25~30min 100%B 4 30~35min 95%A+5%B

Embodiment 2

[0036] Embodiment 2 (75mm inner diameter L&L4003 preparative column packing)

[0037] Using Load&Lock dynamic axial compression and static locking technology, the filler is styrene-divinylbenzene copolymer (reversed phase packing Agilent PLRP-S), the pore size is 10nm, the particle size is 10μm, and the column packing density is 0.33g / mL. Bed pressure 650psi, using Varian chromatography packing system, 370g dry powder filler, 2L methanol after stirring and homogenizing, poured into the L&L4003 preparative column with an inner diameter of 75mm, the compression ratio is 3:1, and the carrier gas is N 2 , adjust the carrier gas pressure so that the pressure of the oil pressure gauge is 2000psi, and the dynamic axial compression reaches a column bed height of 26cm.

Embodiment 3

[0038] Example 3 Reverse-phase cyclization, reverse-phase purification and reverse-phase desalting of vasopressin deamidation impurity precursor crude raw material

[0039] Instrument: Varian SD-1 high pressure liquid phase preparation system

[0040] Chromatographic column: self-packed preparative column Load&Lock4003 75×260mm in Example 2, PLRP-S 10μm 10nm

[0041] The crude product of vasopressin deamidation impurity precursor is the crude product of vasopressin deamidation impurity precursor obtained by cleavage and drying by solid phase synthesis method, and its structural formula is Cys-Tyr-Phe-Gln-Asn-Cys-Pro-Arg-Gly of trifluoroacetate.

[0042] The crude vasopressin deamidation impurity precursor solution is a 5 g / L solution formed by dissolving the crude vasopressin deamidation impurity precursor in 5% acetonitrile aqueous solution.

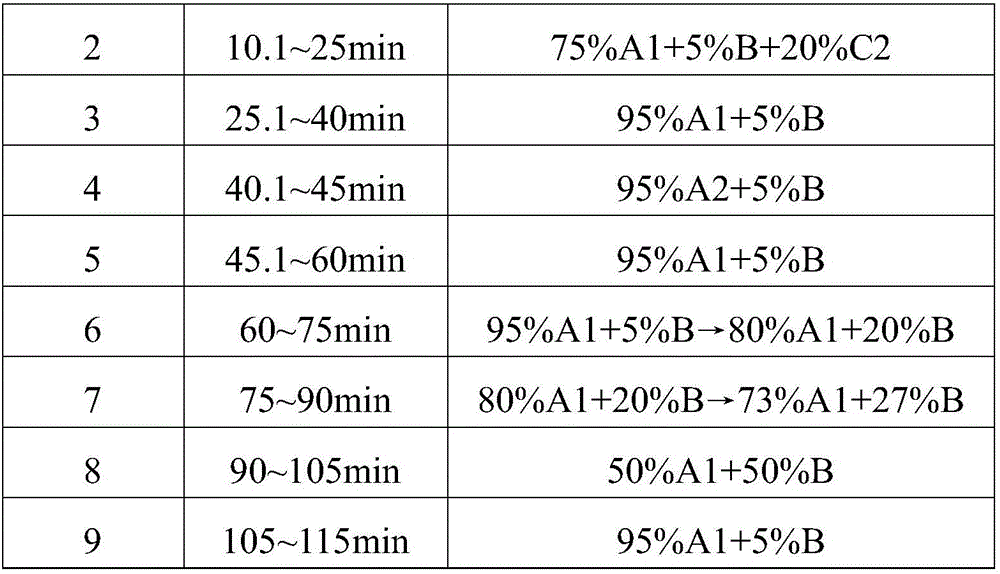

[0043] Mobile phase A1 is purified water, A2 is 0.03 volume percent H 2 o 2pH is 7.5 NaOH aqueous solution, the mobile phase B is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com