Porcelain tile surface treatment process

A technology of surface treatment and porcelain tiles, which is applied in the direction of manufacturing tools, metal processing equipment, explosion generating devices, etc., to improve processing efficiency, optimize production technology, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

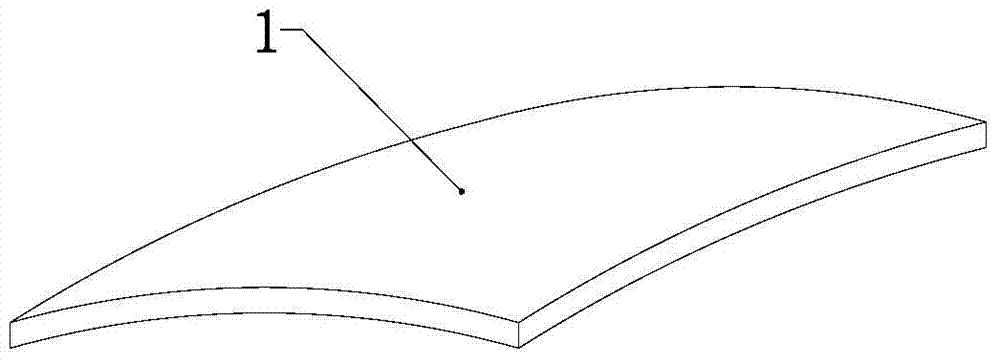

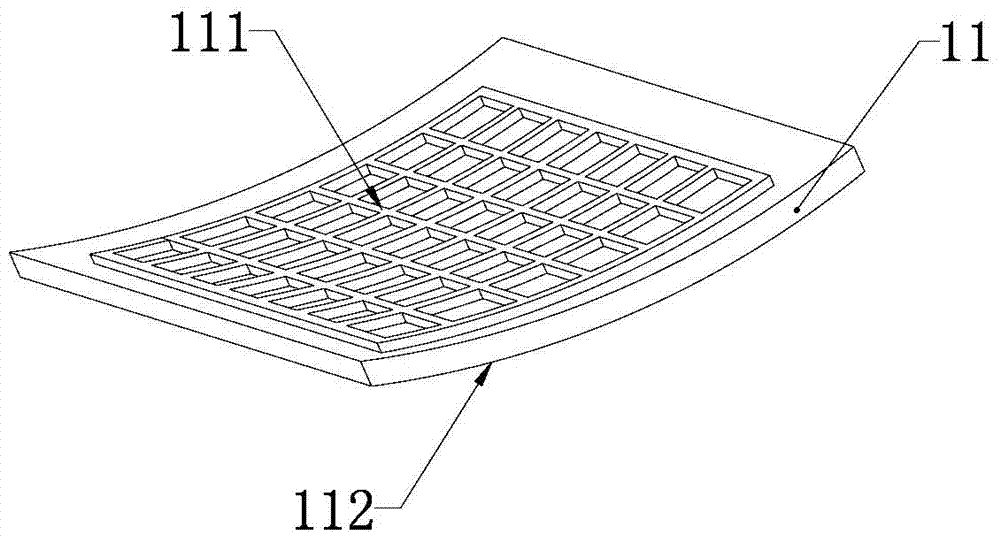

[0024] Now take the deformed ceramic tile 11 processed by the kiln process by the shot blasting process as an example to illustrate the present invention, the structure of the deformed ceramic tile 11 is as follows image 3 As shown: the front side 112 of the deformed ceramic tile 11 is a smooth surface, which is the decorative surface that needs to be further processed in the future, and a series of sunken small grids are arranged on the back side 111, which are mainly used for matching with the ground or wall when used in the future. The reverse surface 111 is deformed into a turtle-back shape with a low middle circumference and a high side.

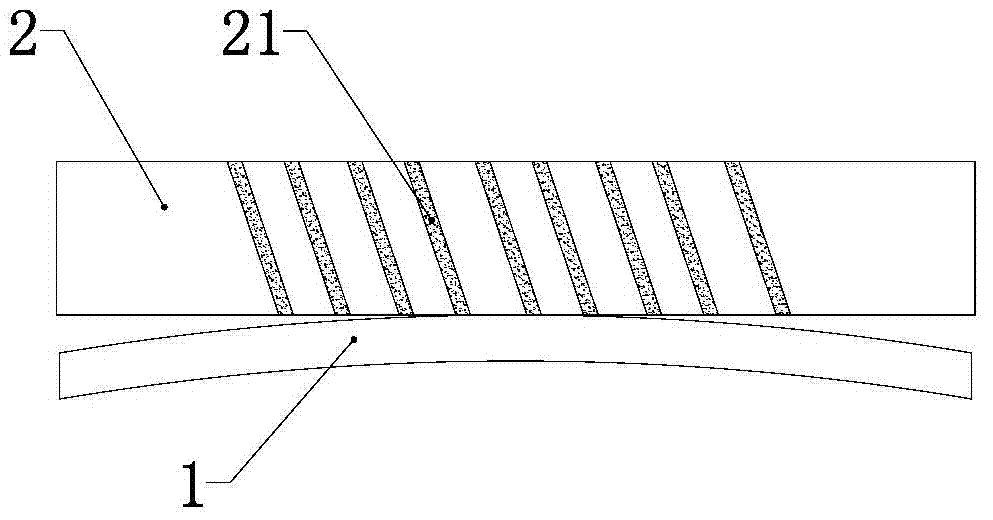

[0025] Such as Figure 5 with Image 6 As shown, the present invention uses a shot blasting device to perform the shot blasting process. The shot blasting device is mainly composed of a transmission bracket 3 and a shot blaster: the deformed ceramic tile 11 is placed on the transmission bracket 3 with the reverse side 111 facing upwar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com