Aluminum alloy mirror polishing equipment and polishing method

A mirror polishing and aluminum alloy technology, which is applied in the field of mechanical processing, can solve the problems of insufficient automation and poor commonality of aluminum alloy polishing machines, so as to improve stability and excellent rate, improve machine dynamic rate, and reduce company costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

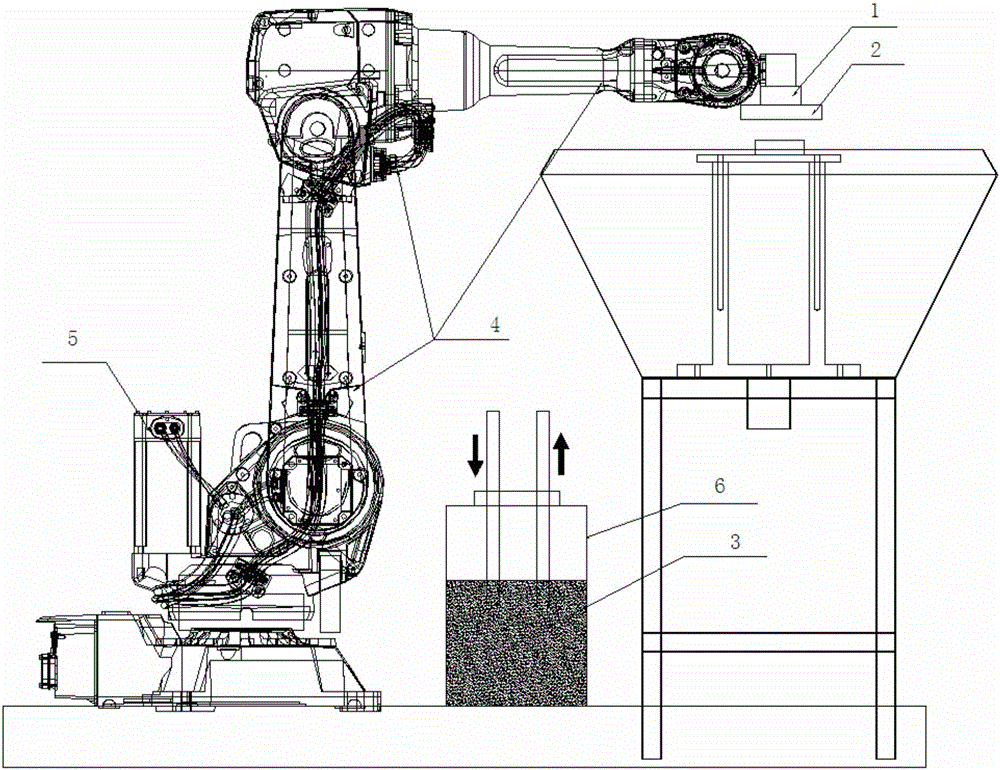

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

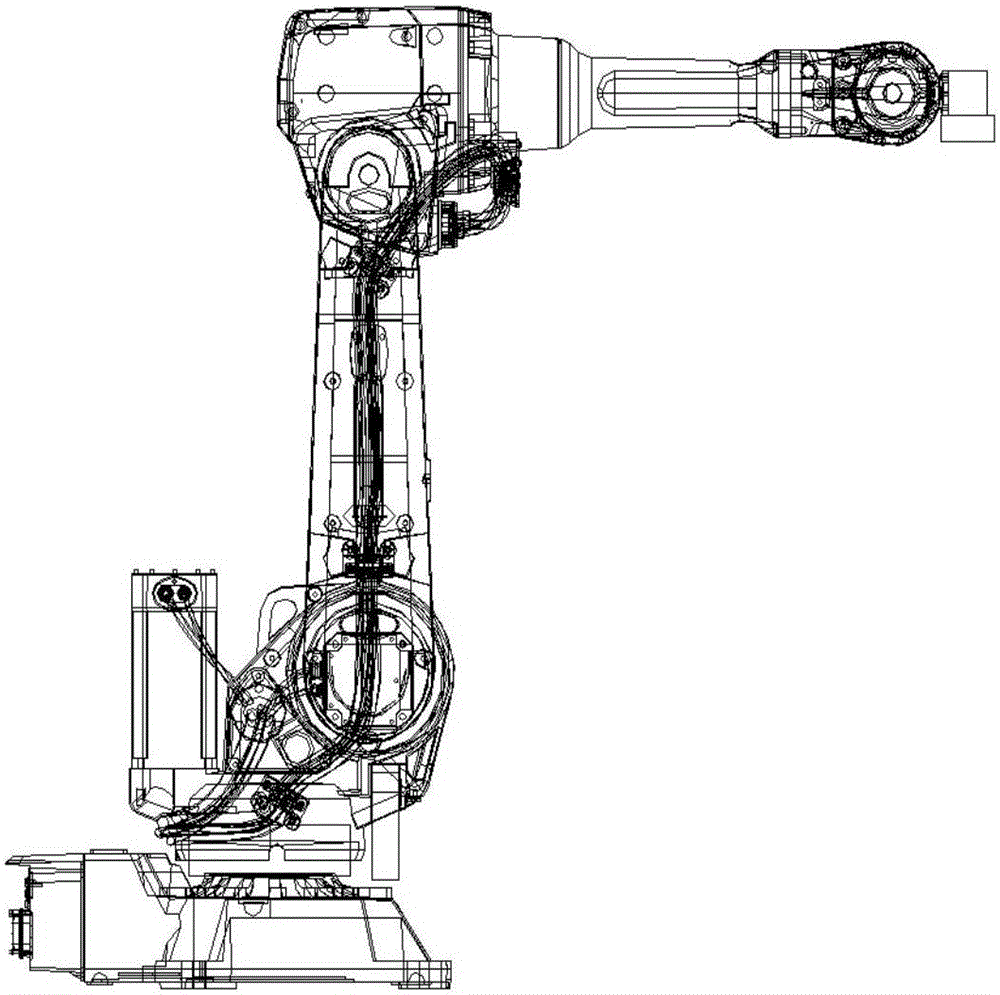

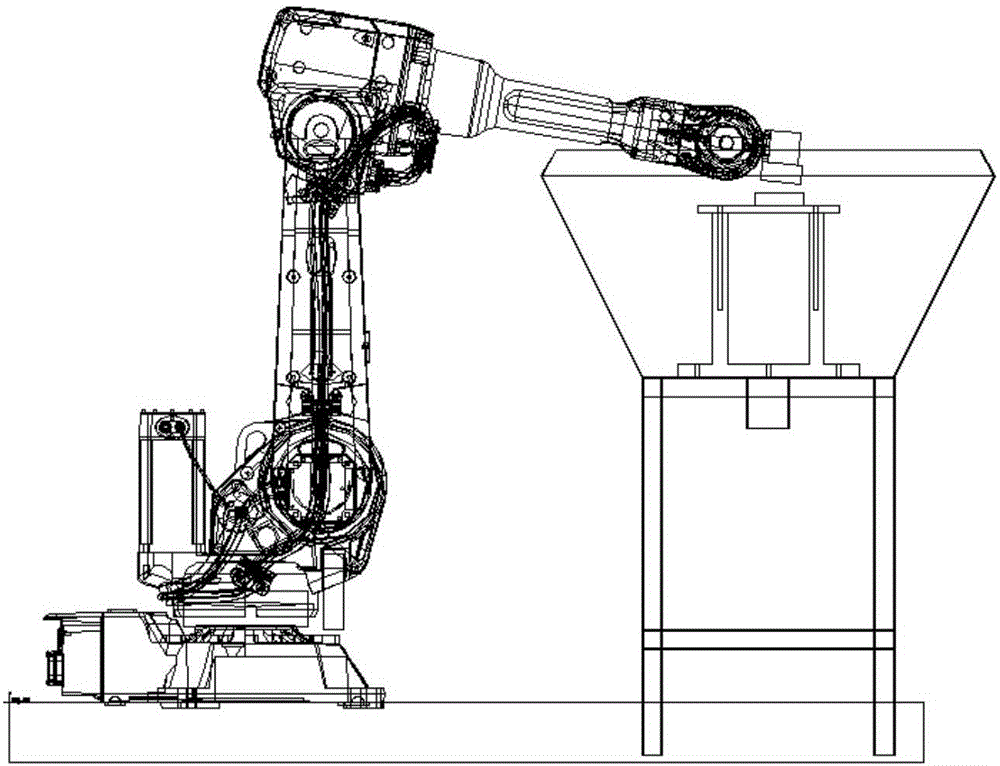

[0029] An aluminum alloy mirror polishing equipment, the aluminum alloy mirror polishing equipment includes a pneumatic grinder 1, a wool polishing sheet 2, a liquid polishing wax 3, a six-axis manipulator 4, a control mechanism 5, the pneumatic grinder and the six-axis Manipulator connection, the wool polishing sheet is arranged on the pneumatic grinding machine and connected with the six-axis manipulator, the control mechanism controls the six-axis manipulator and liquid polishing wax, and the liquid polishing wax is stored in the pressure tank 6 , the pressure tank 6 is controlled by the control mechanism 5, and the control mechanism 5 can write a program to control the movement of the manipulator according to the shape of the polished product, and the manipulator drives the wool polishing sheet and liquid polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com